Mine air conditioner

An air-conditioning and mine technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve the problems of different lengths of heat dissipation circulation channels, difficult control, uneven heat transfer of heat dissipation circulation channels, etc., to achieve refrigeration The position is easy to control, the installation and maintenance are convenient, and the cooling effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

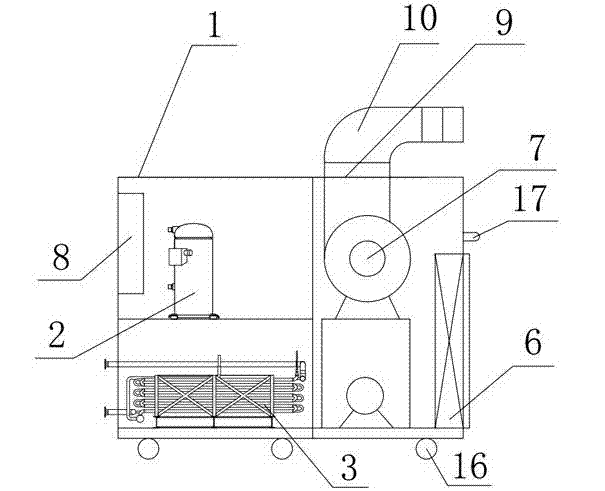

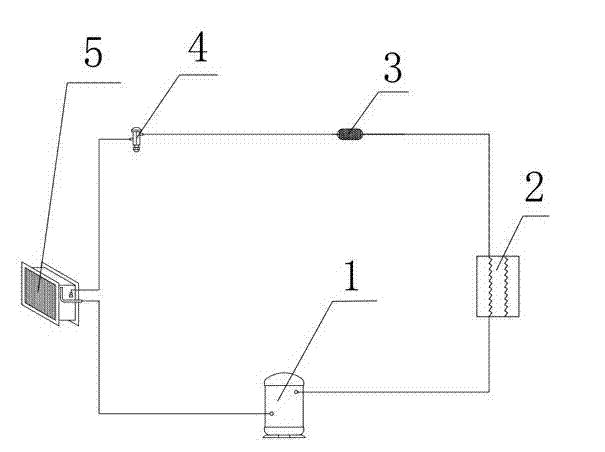

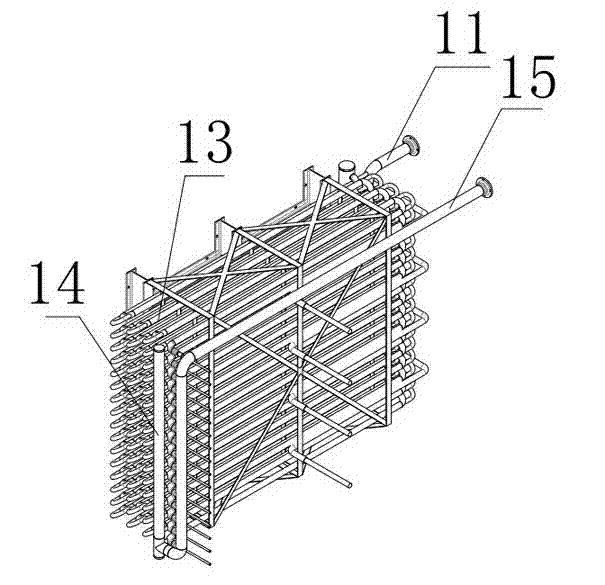

[0018] As shown in the figure: a mine air conditioner, including a box 1, a compressor 2, a condenser 3, a dry filter 4, a throttling device 5, an evaporator 6, a blower 7 and a control box 8, the box 1 is An air outlet 9 is provided, and an air supply pipe 10 is arranged on the air outlet 9, and the compressor 2, the condenser 3, the dry filter 4, the throttling device 5 and the evaporator 6 are connected by pipelines to form a closed circulation loop , the condenser 3 includes a water inlet pipe 11, a water guide pipe 12, a plurality of heat exchange tubes 13, a water collection pipe 14 and a water outlet pipe 15, and a plurality of sets of heat exchange pipes 13 are arranged in parallel between the water guide pipe 12 and the water collection pipe 14 , the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com