Lubrication system of piston ring of internal-combustion engine and upper portion scraper ring of adjacent cylinder sleeve

A lubrication system and scraper ring technology, applied to piston rings, mechanical equipment, engine components, etc., can solve problems such as increased wear and exhaust emissions of automobile engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0034] While wiper rings are suitable for many types of internal combustion engines, the one shown here is installed on a two-stroke opposed cylinder opposed piston (OPOC) engine.

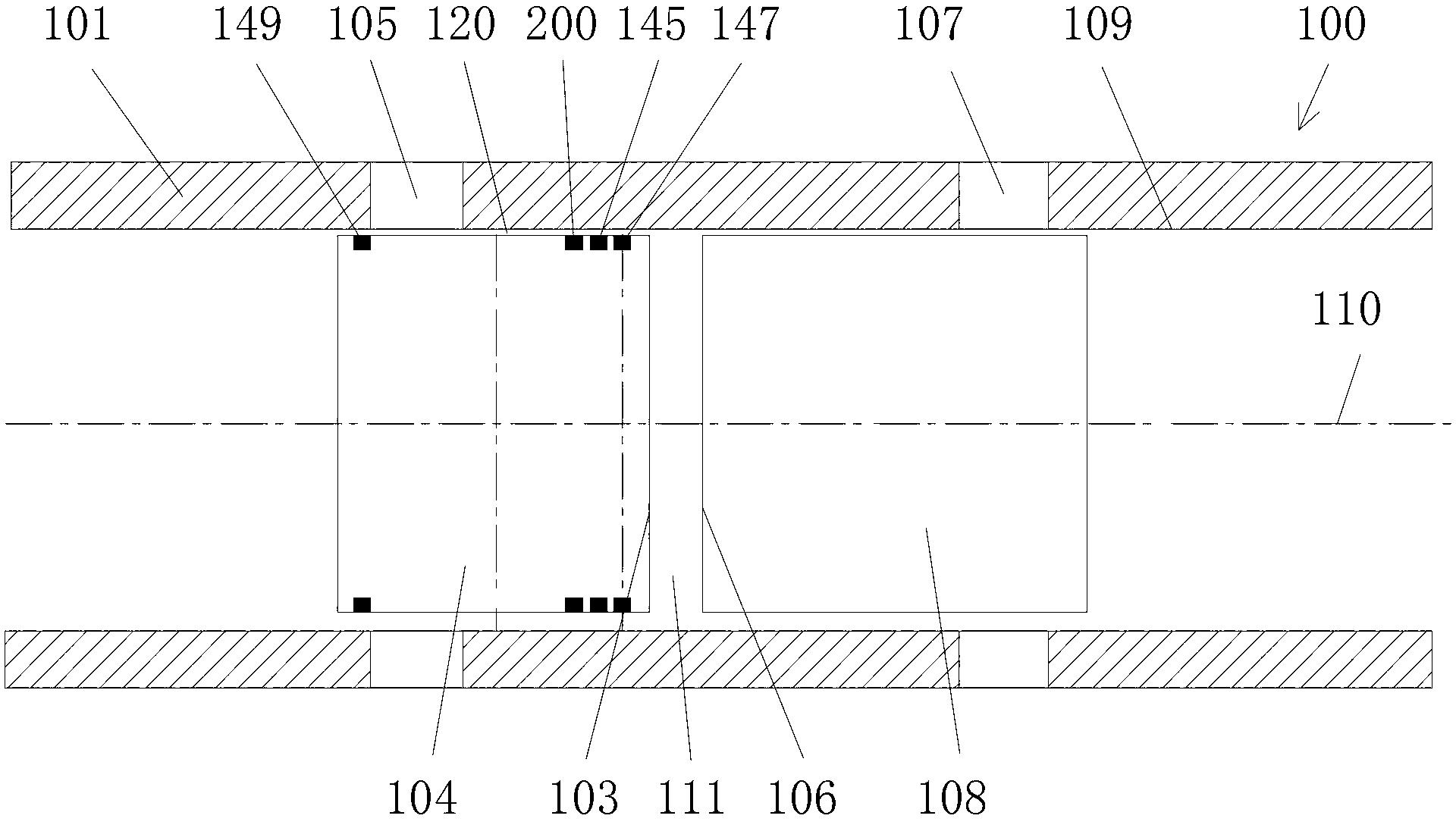

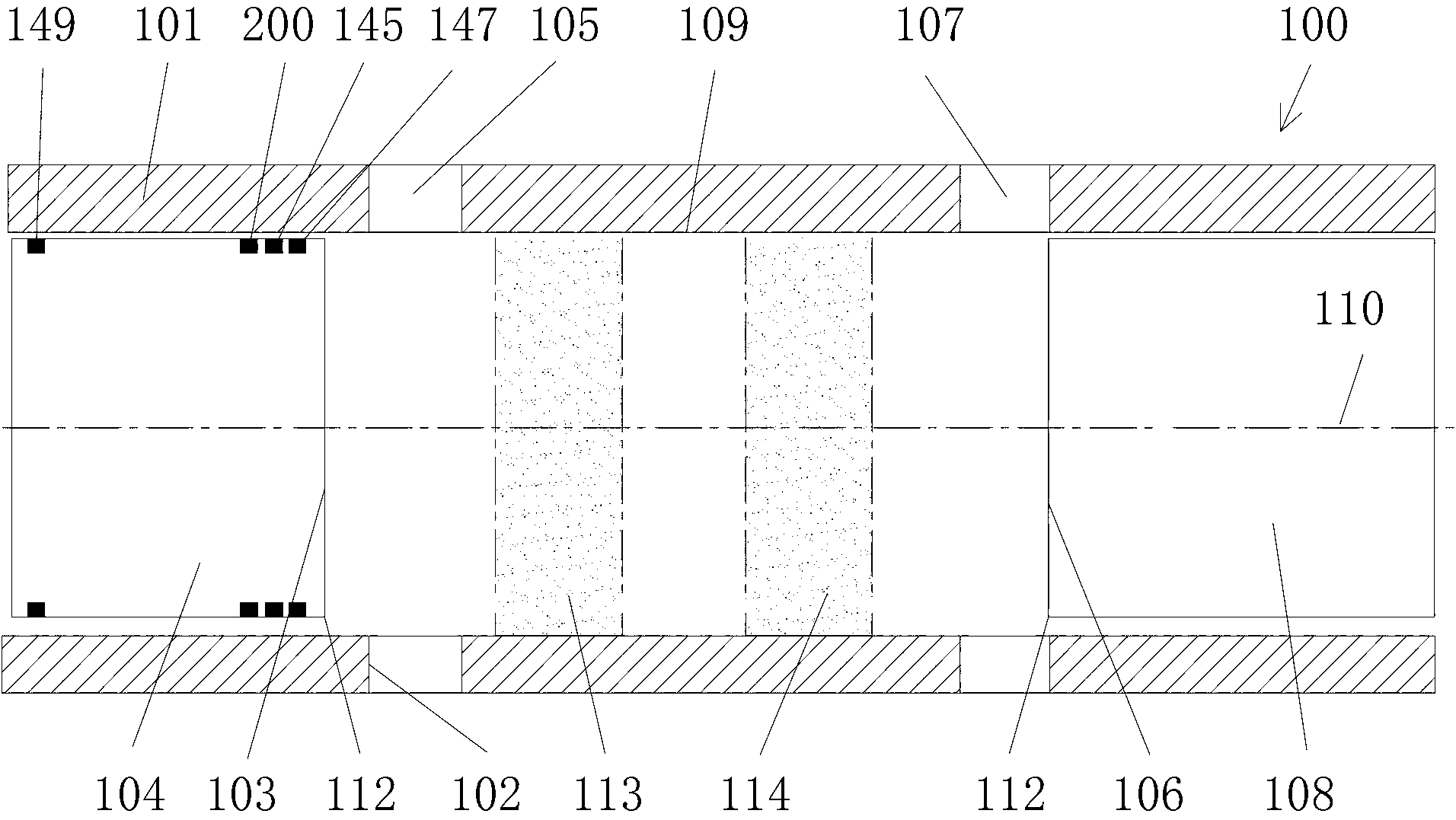

[0035] Figure 1 (a) is a schematic diagram of the piston ring of an internal combustion engine of the present invention and the upper scraper ring lubrication system of the adjacent cylinder liner when the outer piston is close to the top dead center, and Figure 1 (b) is a piston ring of an internal combustion engine of the present invention Schematic diagram of the outer piston approaching bottom dead center in the upper wiper ring lubrication system with the adjacent cylinder liner, see Fig. 1(a) and Fig. 1(b), in the left Side single cylinder 100 , outer piston 104 , inner piston 108 . In FIG. 1( a ), the two pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com