Over-positioning elastic push-pull cable flexible shaft

An over-positioning and elastic technology, applied in the direction of the linear motion axis and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

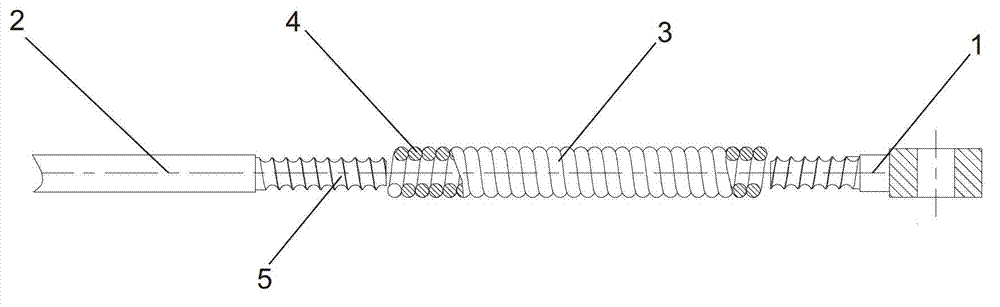

[0021] Such as figure 1 As shown, an over-positioning elastic push-pull cable flexible shaft is used for the gear selection of the transmission, including a cable head 1, a cable rod 2 and a spring 3, the cable head 1 is connected with the gear selection fork 8 of the transmission, and the cable The rod 2 is connected with the gear lever at the operating end, the cable head 1 and the cable rod 2 are split structures, and the two ends of the spring 3 are respectively provided with a spring coil fixed section 4, and the spring 3 in the spring coil fixed section 4 is in phase. Each adjacent turn is welded to each other to form a spiral tube with certain rigidity. One end of the cable head 1 and the cable rod 2 is respectively fixed with a connecting screw 5 adapted to the fixed section 4 of the spring coil, and the spring coils at both ends of the spring 3 are fixed. The segment 4 is screwed and connected with the connecting screw 5 of the cable head 1 and the cable rod 2 re...

Embodiment 2

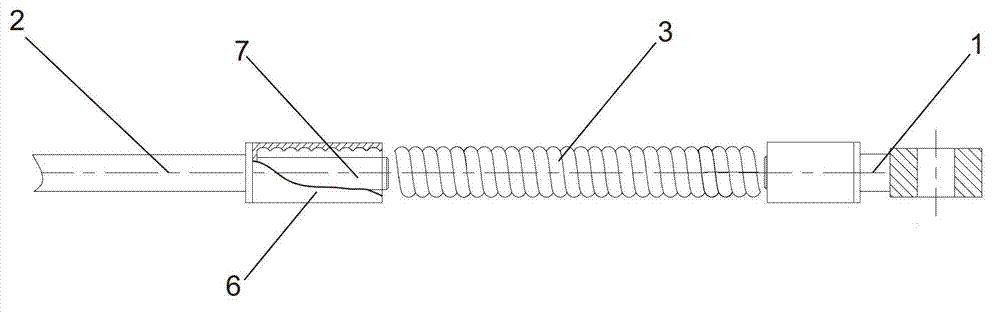

[0024] Such as figure 2 As shown, one end of the cable head 1 and the cable rod 2 is respectively fixed with a steel spiral sleeve 6, and one end of the cable head 1 and the cable rod 2 is respectively provided with a flange, and the flange and the spiral sleeve 6 The end face of the bottom plate is connected by four bolts. The spiral sleeve 6 is cylindrical, one end of which is open, and the other end is closed by a bottom plate. The inner wall of the spiral sleeve 6 is provided with a spiral groove matching the spring 3 in the natural state. The inner diameter of the spring 3 in the state is adapted to the core rod 7, and the two ends of the spring 3 are respectively screwed and connected with the spiral sleeve 6 of the cable head 1 and the cable rod 2 in a thread-like manner and sleeved on the core rod 7. The core rod radially limits the spring turns, combined with the axial limit of the spiral grooves on the spring turns, so as to realize the fast and firm connecti...

Embodiment 3

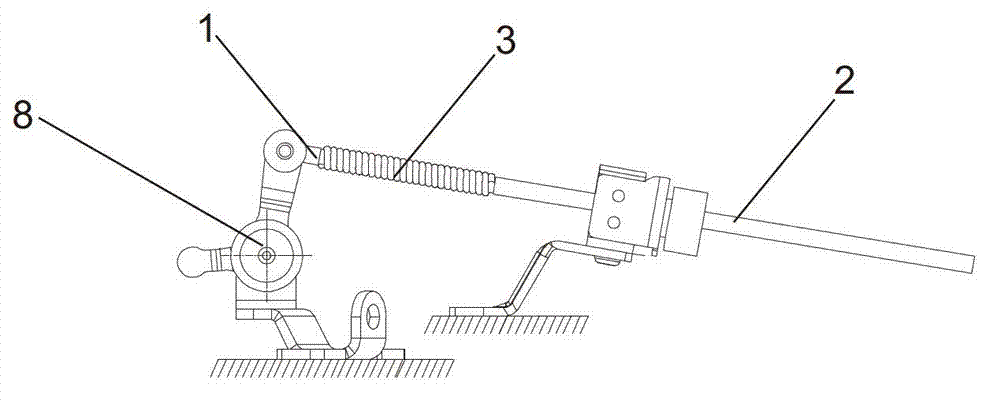

[0026] Such as Figure 6 As shown, an over-positioning elastic push-pull cable flexible shaft includes a cable head 1, a cable rod 2 and a spring 3, and is simultaneously applied to the gear selection and shifting of the transmission, the gear selection fork 8 and the shift fork of the transmission The 9 is respectively connected with a root through positioning elastic push-pull cable flexible shaft, and two cross-position elastic push-pull cable flexible shafts are connected in parallel on the shift lever again. The plane of rotation of the shift fork 9 is perpendicular to the plane of rotation of the selector fork 8 . The process of driving the shift fork 9 through the flexible shaft of the positioning elastic push-pull cable is the same as the process of driving the shift fork 8, except that the plane where the movement is located is different. , that is, in the first, third and fifth gears, the shift fork 9 is pushed to the limit positioning position at one end by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com