A kind of bendable PVC rigid-flexible composite board and its preparation method

A composite board, rigid-flex technology, applied in the field of foldable PVC rigid-flex composite board and its preparation, can solve the problems of poor connection stability of the board, cumbersome construction process, affecting the decorative effect, etc., to achieve beautiful decorative effect, simple and convenient splicing, Easy to operate effect

Active Publication Date: 2022-06-03

GREENTOWN DECORATION ENG GRP CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

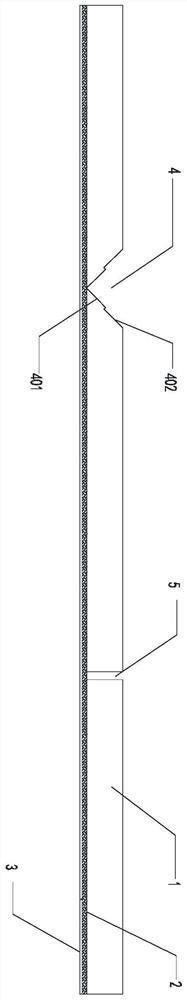

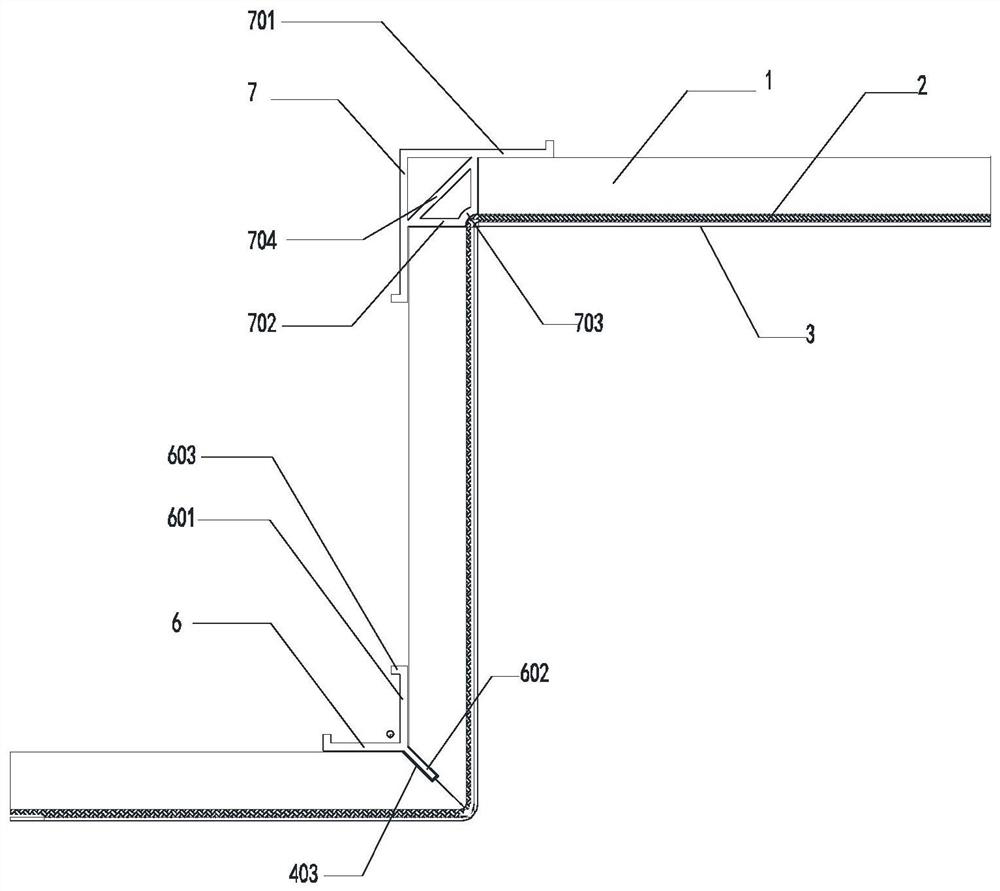

[0005] The purpose of the present invention is to overcome the poor bending resistance and easy breakage of the composite boards in the prior art. When they are used for wall or floor decoration, when corners are encountered, the boards must be sawed and then spliced through internal corner lines or external corner lines. , the construction process is cumbersome, the connection stability of the boards is poor, and the decorative effect is affected. A PVC rigid-flexible composite board with bendable angles and its preparation method are provided. Layer compounding, so that the PVC rigid-flexible composite board has good mechanical properties, not easy to break and deform, and at the same time, it can be bent at the corner without cutting and connecting with male and female corners, which simplifies the construction process , to ensure the decorative effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0040] A kind of foldable PVC rigid-flexible composite board, in terms of mass fraction, the rigid layer raw materials include: 14% PVC resin, 18%

Embodiment 2

[0047] A foldable angle PVC rigid-flexible composite board, in terms of mass fraction, the rigid layer raw materials include: 13% PVC resin, 15%

Embodiment 3

[0054] An angle-foldable PVC rigid-flex composite board, in terms of mass fraction, the rigid layer raw materials include: 15% PVC resin, 20%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a bendable PVC rigid-flexible composite board and a preparation method thereof. It comprises a rigid layer, a flexible layer and a facing layer. The rigid layer is provided with male corner grooves and female corner grooves. The raw materials of the rigid layer include: PVC resin, Calcium zinc composite stabilizer, stearic acid, polyethylene wax, polyacrylate, chlorinated polyethylene, bamboo wood powder, calcium carbonate stone powder, azodicarbonamide, antibacterial filler and sodium iodide; flexible layer raw materials include: PVC Resin, PVC softener, calcium zinc complex stabilizer, stearic acid, polyethylene wax, calcium carbonate stone powder, azodicarbonamide, antibacterial filler and sodium iodide. The invention adopts a rigid-flexible composite structure, which has good impact resistance; it can be bent along the yin and yang corner grooves, and the yin and yang corners can be seamlessly spliced; antibacterial fillers are added to improve the mechanical properties of the board and make the board waterproof and mildew-proof; the rigid layer , The flexible layer and the decorative layer are hot-pressed and compounded together, the process is simple, the use of glue is avoided, and it is more energy-saving and environmentally friendly.

Description

A kind of foldable PVC rigid-flex composite board and preparation method thereof technical field The present invention relates to building material technical field, especially relate to a kind of foldable angle PVC rigid-flexible composite board and preparation thereof method. Background technique PVC is a thermoplastic polymer material, which is often combined with wood (wood cellulose, plant cellulose), stone Powder and other mixtures are processed into new composite decorative materials such as wood-plastic panels and stone-plastic panels, because they have both wood and plastic or stone powder and plastic. Its performance and characteristics have been widely used in interior decoration and other fields. [0003] The traditional wood-plastic board or stone-plastic board has poor bending resistance and is easy to break. When used for wall or ground decoration, it encounters a corner, The board must be sawed and then spliced through the inner corner or the outer c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B32B37/10B32B27/30B32B27/08B32B27/06B32B27/32B32B27/10B32B27/12B32B15/082C08L27/06C08L23/06C08L33/04C08L23/28C08L97/02C08K13/06C08K9/06C08K3/22C08K3/26C08K5/09C08J9/10E04F13/073E04F13/075E04F13/076E04F13/08

CPCB32B37/10B32B27/304B32B27/08B32B27/06B32B27/32B32B27/10B32B27/12B32B15/082C08J9/103C08J9/0061C08J9/0023C08J9/0066C08J9/009E04F13/073E04F13/0866E04F13/0875E04F13/0892C08K2003/265C08K13/06C08K9/08C08K9/06C08K2201/011C08K2003/2241C08K3/26C08K5/09C08J2327/06C08J2423/06C08J2433/04C08J2423/28C08J2497/02C08J2203/04B32B2307/558B32B2307/7145B32B2307/7265B32B2307/306

Inventor 王永根朱快赖圣场杨大平曹晓花陈子豪裴旭徐廷博岳朔颐

Owner GREENTOWN DECORATION ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com