Multifunctional modified asphalt and preparation method thereof

A modified asphalt, multi-functional technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of high equipment requirements, complex production process, increased costs, etc., to achieve strong coating ability, high softening point, saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

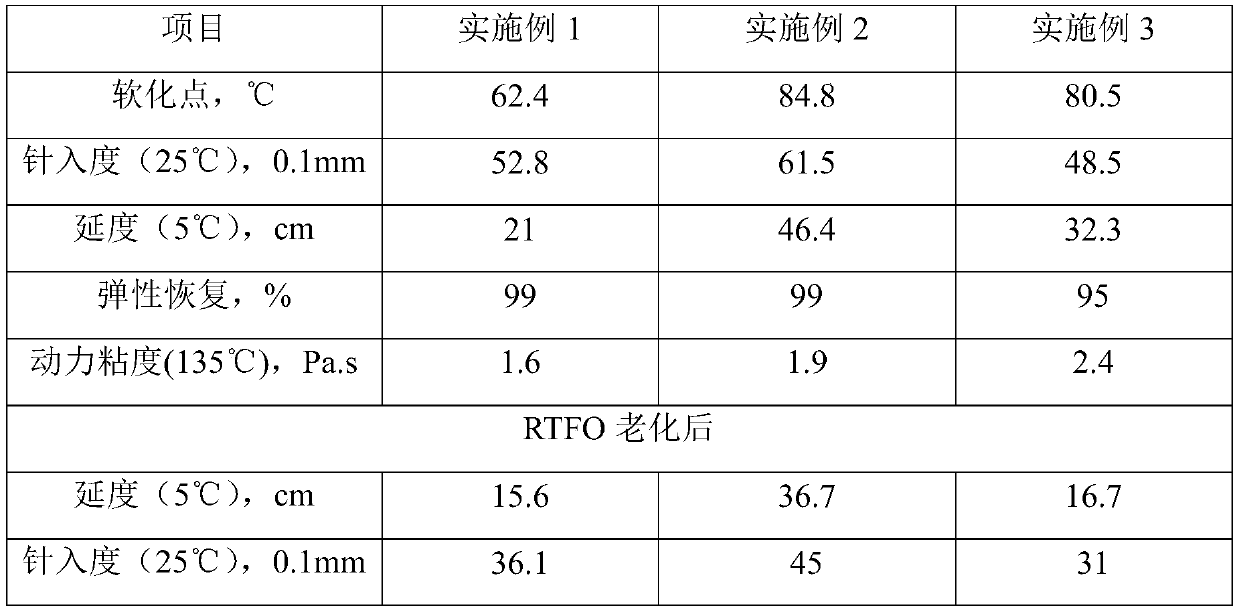

Embodiment 1

[0036] A multi-functional modified asphalt, composed of 15% modified materials, 2% SBS, 1% SBR, 5% modified tackifier, 2% polymer surfactant, 10% APAO, 10% The filler and the balance are base asphalt, which are uniformly mixed.

[0037] The preparation method of the above-mentioned multifunctional modified asphalt, the specific operation steps are:

[0038] (1) Weigh 15% of modified material, 2% of SBS, 1% of SBR, 5% of modified tackifier, 2% of polymer surfactant, 10% of APAO, 10% of filler, the balance is base asphalt;

[0039] (2) Preheat the base asphalt taken in proportion to 120°C;

[0040] (3) Add the modified material in proportion to the preheated base asphalt and stir until uniform, and keep the temperature at 120°C;

[0041] (4) Raise the temperature to 170°C, add SBS, SBR, modified viscosifier, polymer surfactant, APAO and fillers to the above mixture in proportion, and shear at a constant temperature for 45 minutes to obtain a multifunctional modification asph...

Embodiment 2

[0044] A multi-functional modified asphalt, composed of 30% modified materials, 3% SBS, 2% SBR, 10% modified tackifier, 5% polymer surfactant, 15% APAO, 15% The filler and the balance are base asphalt, which are uniformly mixed.

[0045] The preparation method of the above-mentioned multifunctional modified asphalt, the specific operation steps are:

[0046] (1) Weigh 30% of modified material, 3% of SBS, 2% of SBR, 10% of modified tackifier, 5% of polymer surfactant, 15% of APAO, 15% of filler, the balance is base asphalt;

[0047] (2) Preheat the base asphalt taken in proportion to 140°C;

[0048] (3) Add the modified material in proportion to the preheated base asphalt and stir until uniform, and keep the temperature at 140°C;

[0049] (4) Raise the temperature to 180°C, add SBS, SBR, modified viscosifier, polymer surfactant, APAO and fillers to the above mixture in proportion, and shear at constant temperature for 50 minutes to obtain multifunctional modification asphal...

Embodiment 3

[0052] A multi-functional modified asphalt, composed of 35% modified materials, 3% SBS, 3% SBR, 12% modified tackifier, 7% polymer surfactant, 16% APAO, 20% The filler and the balance are base asphalt, which are uniformly mixed.

[0053] The preparation method of the above-mentioned multifunctional modified asphalt, the specific operation steps are:

[0054] (1) Weigh 35% of modified material, 3% of SBS, 3% of SBR, 12% of modified tackifier, 7% of polymer surfactant, 16% of APAO, 20% of filler, the balance is base asphalt;

[0055] (2) Preheat the base asphalt taken in proportion to 110°C;

[0056](3) Add the modified material in proportion to the preheated base asphalt and stir until uniform, and keep the temperature at 110°C;

[0057] (4) Raise the temperature to 160°C, add SBS, SBR, modified viscosifier, polymer surfactant, APAO and fillers to the above mixture in proportion, and shear at constant temperature for 30 minutes to obtain multifunctional modification asphalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com