Process and for producing Jinlun Non-wowen cloth by spinning-bonding method its device and jinlun non-woven cloth products

A technology of polyamide and non-woven fabrics, applied in the field of manufacturing nylon non-woven fabrics, can solve the problems of inability to manufacture nylon non-woven fabrics, failure to achieve one-step fabric formation, complicated equipment and processes, etc., and achieves high elastic recovery rate and dimensional stability. Strong and versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

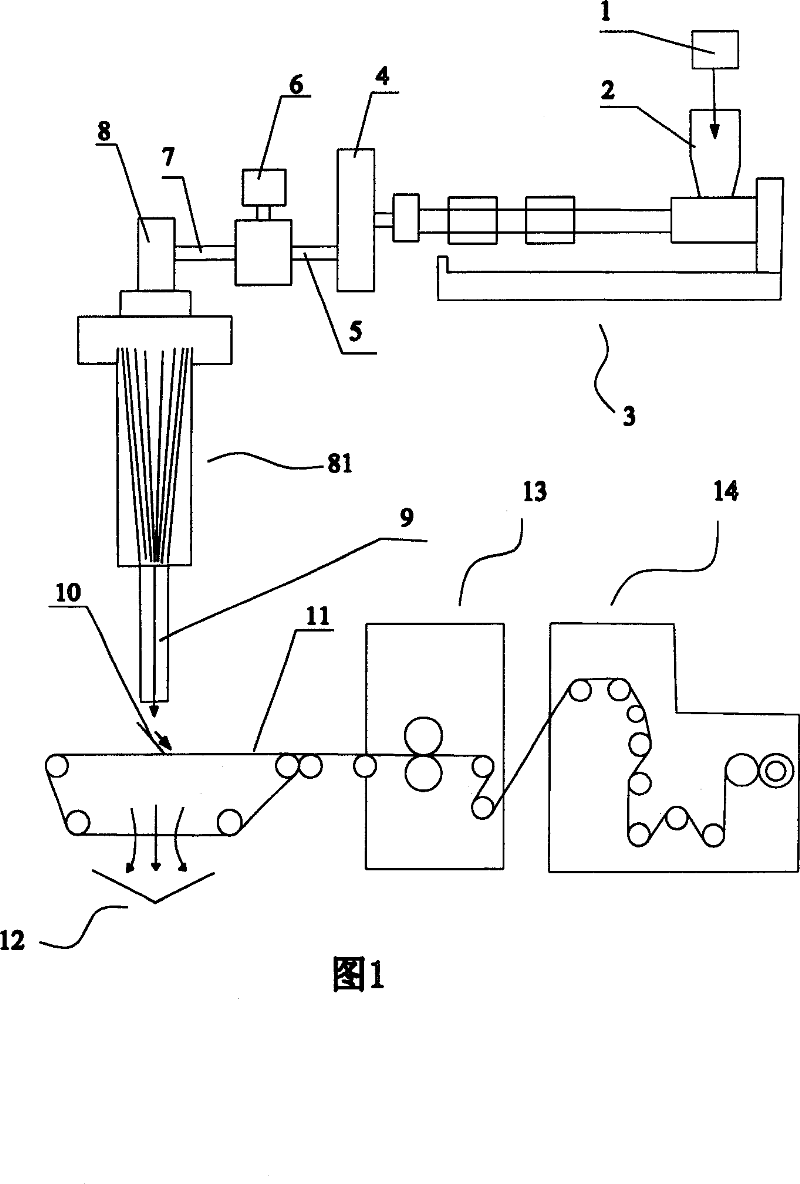

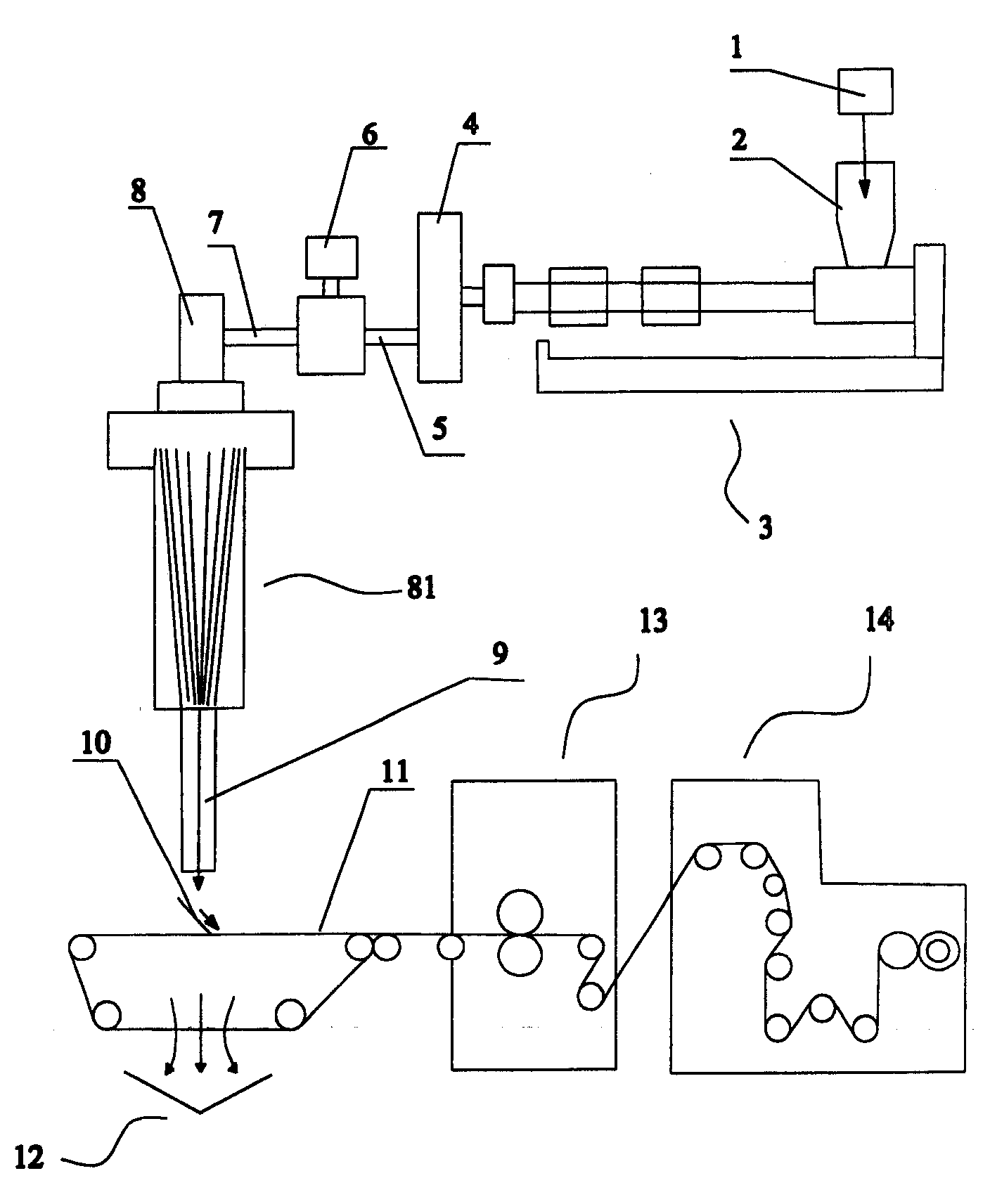

[0033] As shown in Figure 1, the polyamide 6 (PA6) slices are placed in the drying system 1 and dried with hot air at 130°C, and sent to the hopper 2 through the air conveying device, where the PA6 slices are mixed with various additives (such as brighteners, coloring additives and various additives) are fully mixed and sent to the screw extruder 3 for extrusion and melting. The temperature of the extruder is 250°C. After several stages of feeding, compression and metering, the materials are fully melted and mixed Finally, it is sent to the filter 4, where the impurities in the material, such as carbon, ash, etc., are filtered out, and the material enters the metering pump 6 through the melt pipeline 5, and the metering pump evenly and accurately melts the molten material through the distribution pipeline 7. Distributed to each spinning position, the temperature of the melt pipe and the distribution pipe is kept at about 250°C.

[0034] Spinning is carried out in the spinning ...

Embodiment 2~4

[0037] Technological process and equipment are basically the same as embodiment 1, and technological conditions are shown in Table 1:

[0038] Table 1 Nylon non-woven fabric process conditions

[0039] screw extrusion

[0040] The nylon non-woven fabric products obtained by the above process have the characteristics of soft hand feeling, high strength, high elastic recovery rate and bending resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com