Automatic switchover shuttle valve

A technology of automatic switching and shuttle valves, applied in the direction of sliding valves, valve details, multi-way valves, etc., can solve the problems of increasing processing difficulty and achieve the effects of good exhaust effect, simple structure, and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

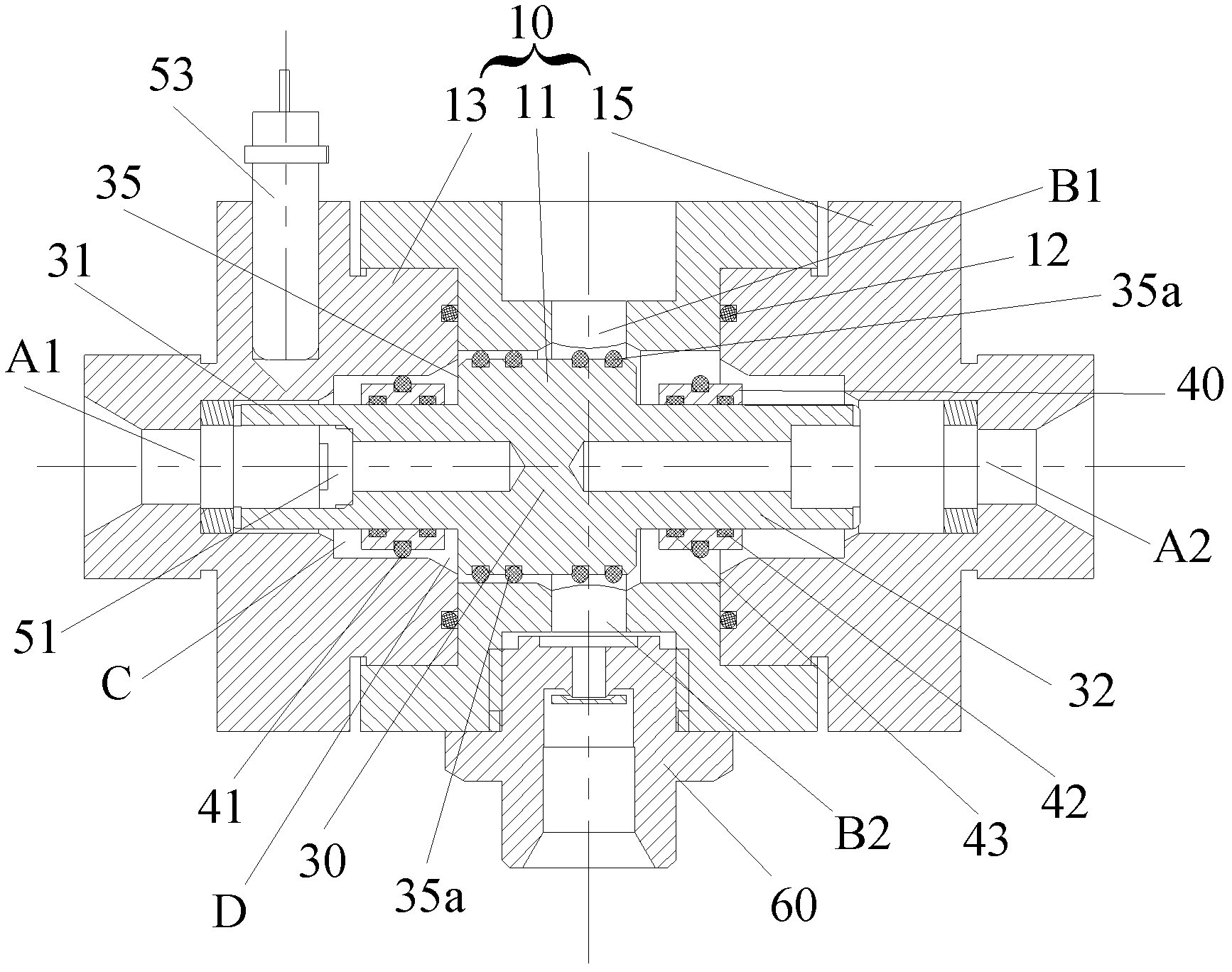

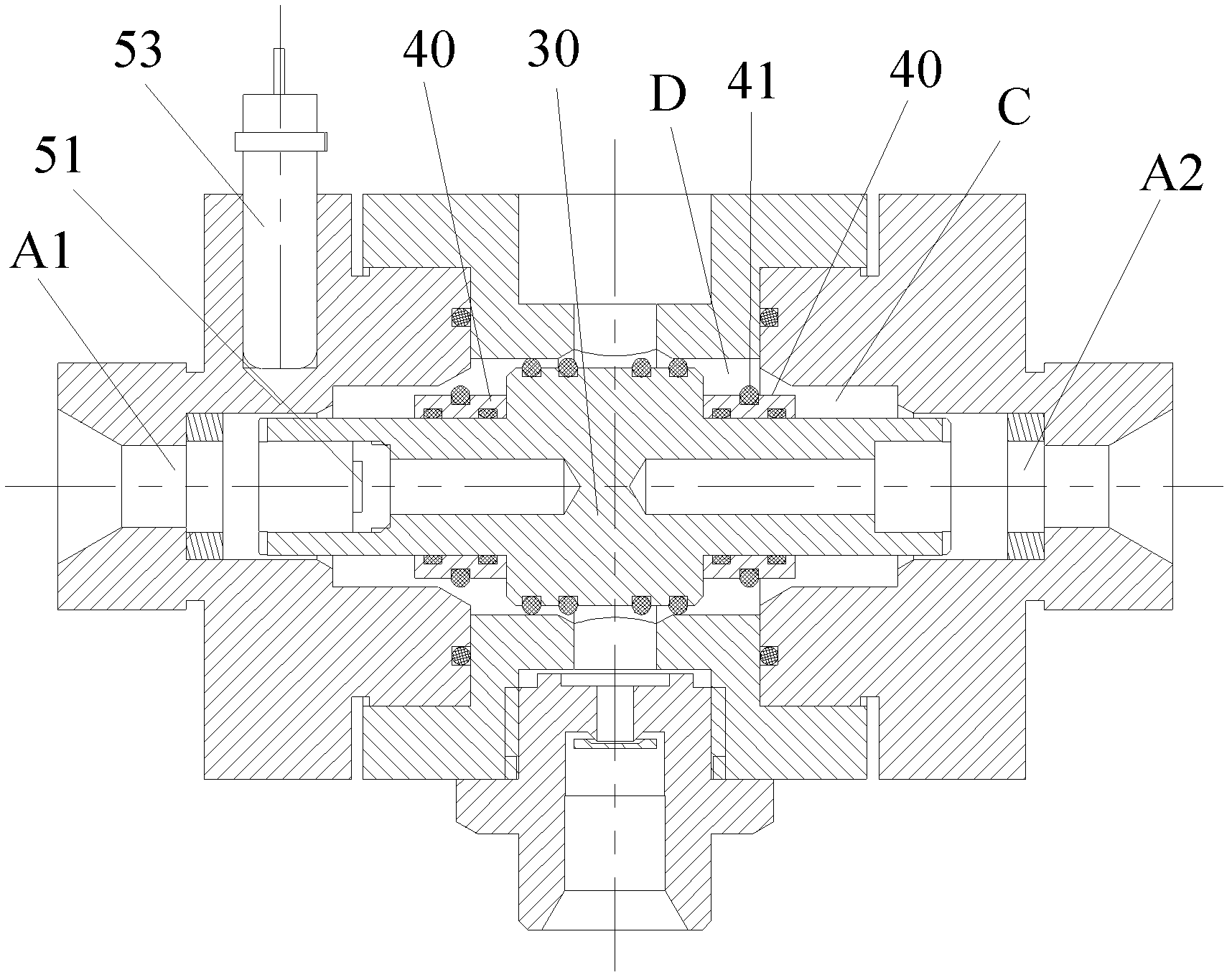

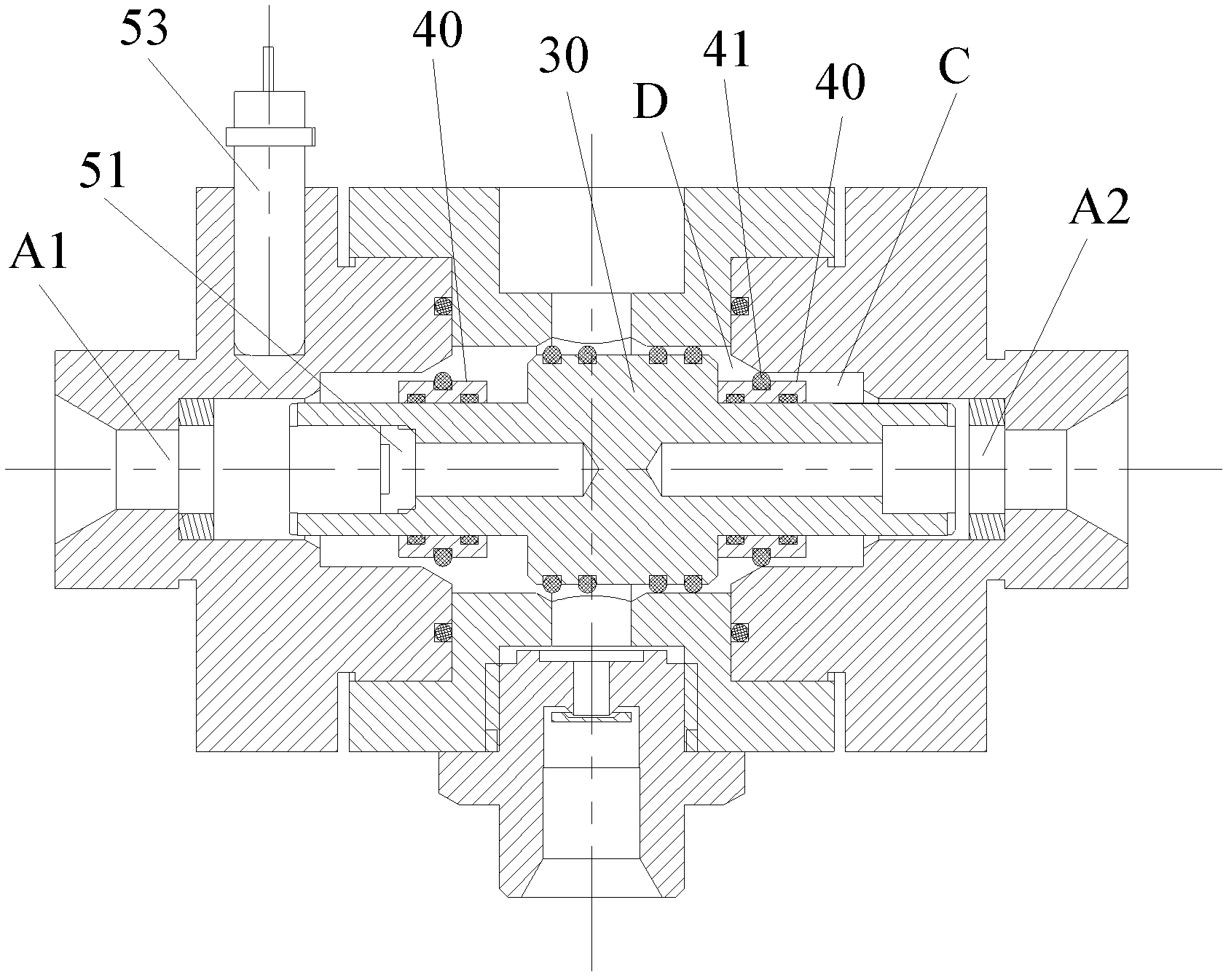

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0029] like figure 1 As shown, the present invention provides an automatic switching shuttle valve, including: a valve body 10 having a valve core moving chamber, and a first air inlet A1 and a second air inlet are formed on the side wall of the valve core moving chamber. Port A2 and the first air outlet B1, wherein the first air inlet A1 and the second air inlet A2 are oppositely arranged; the valve core 30 is located in the valve core moving cavity and has a first extension pointing to the first air inlet A1 The arm 31 and the second arm 32 pointing to the second air inlet A2, between the first arm 31 and the second arm 32 is provided with radially outwardly protruding and connected to the first air outlet B1 The opposite boss 35, wherein the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com