Method for quantitatively detecting alkylphenol polyoxyethylene in daily chemical products

A technology for alkylphenol polyoxyethylene ether and chemical products is applied in the field of quantitative determination of alkylphenol polyoxyethylene ether in daily chemical products, which can solve the problem of large difference in molecular weight, qualitative deviation, and inconsistent relative abundance of fragment ions and other problems, to achieve the effect of simple pre-processing, high accuracy, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

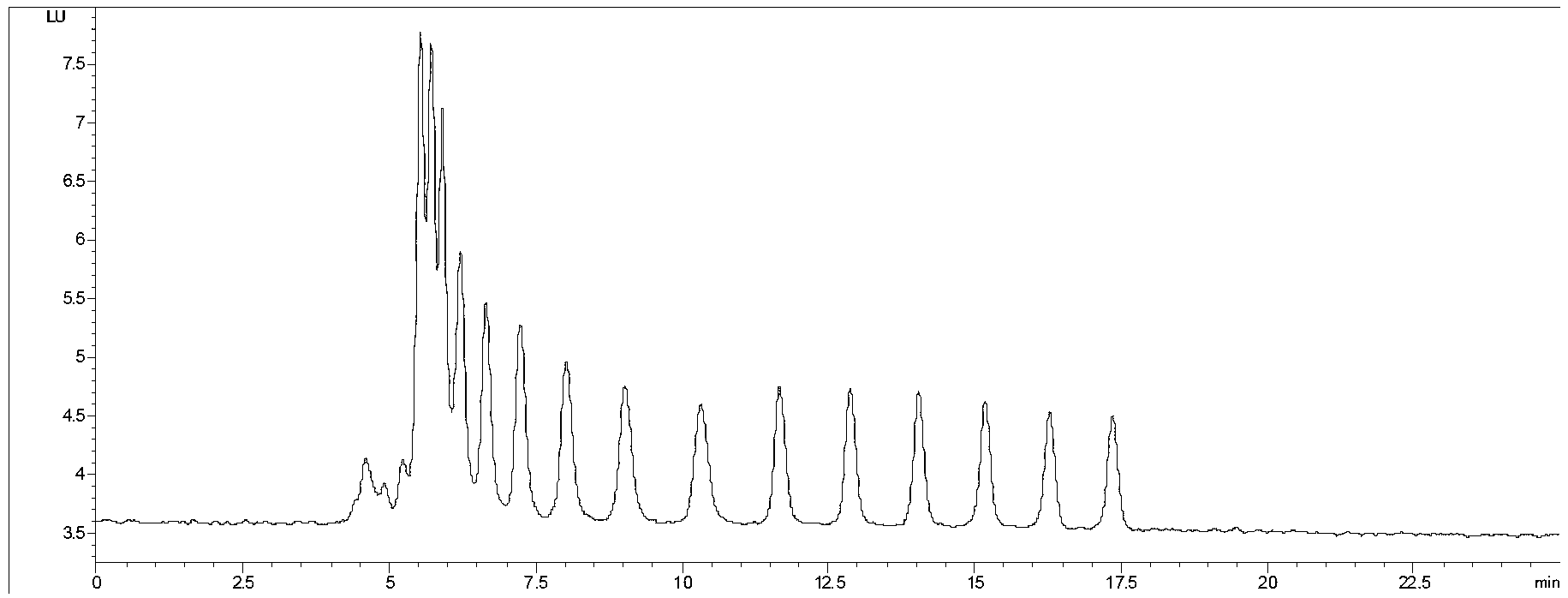

[0041] Nonylphenol polyoxyethylene ether (NP) in the laundry liquid sample of embodiment 1 n EO) and octylphenol ethoxylates (OP n Determination of EO) content

[0042] 1. Preparation of samples

[0043] Accurately weigh 0.5g (accurate to 0.001g) of laundry detergent sample, put it into a 10mL stoppered centrifuge tube, add about 9mL of acetonitrile aqueous solution (8:2, v / v), mix on a vortex oscillator to disperse the sample, Place in an ultrasonic generator for extraction for 15 minutes, and dilute to the mark with aqueous acetonitrile. The extract was centrifuged at 15000r / min for 5min and filtered with a 0.45μm membrane to obtain the test sample.

[0044]Pipette nonylphenol ethoxylates (Nippon Hayashi Junyaku, 100 μg / mL) and octylphenol ethoxylates (Nippon Hayashi Junyaku, 100 μg / mL), and use acetonitrile aqueous solution as a solvent to dissolve the above nonyl Dilute phenol ethoxylates and octylphenol ethoxylates to 2.0mg / L, 4.0mg / L, 10.0mg / L, 20.0mg / L, 50.0mg / L to ...

Embodiment 2

[0083] Example 2 Nonylphenol polyoxyethylene ether (NP) in cream cosmetic sample 1 n EO) and octylphenol ethoxylates (OP n Determination of EO) content

[0084] 1. Preparation of samples

[0085] Same as Example 1

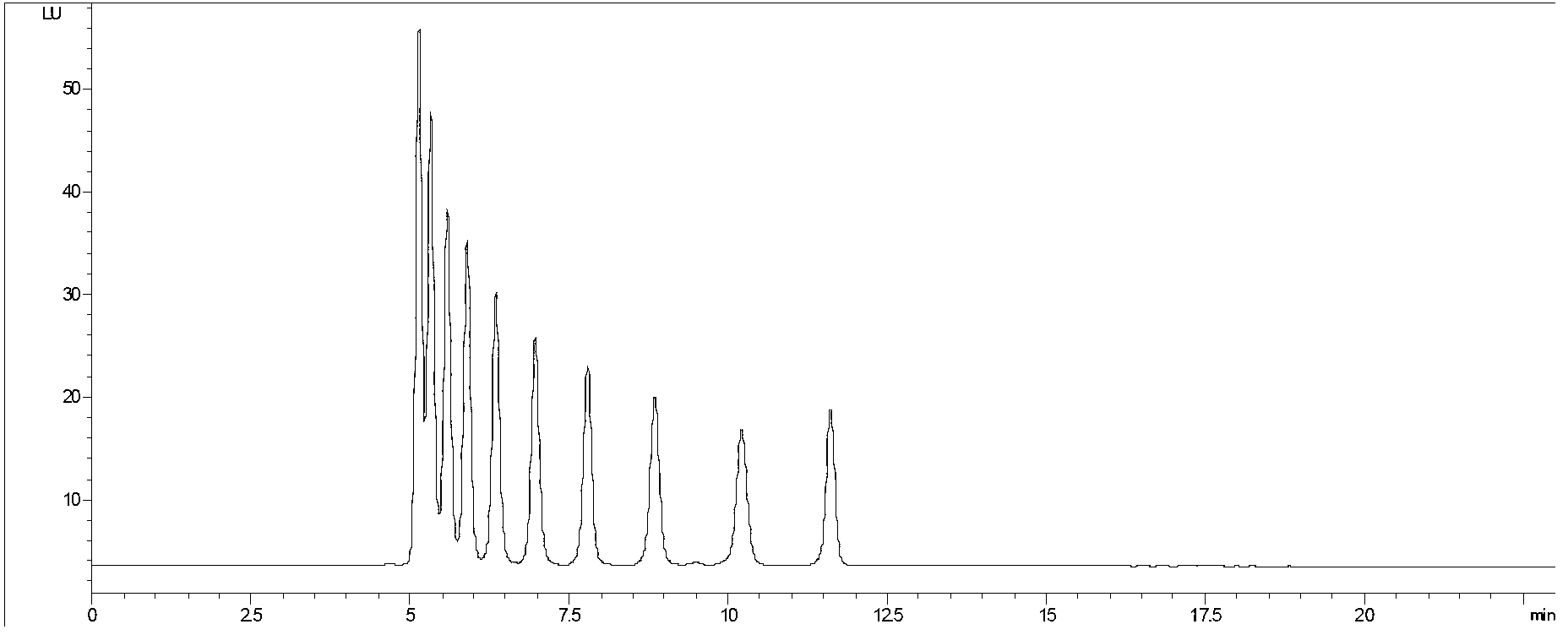

[0086] 2. Determination by HPLC

[0087] With embodiment 1, obtain test sample chromatogram, as Figure 4 Shown, and judging from the peak time that the added substance is NPEO.

[0088] 3. Quantitative calculation

[0089] 3.1 Calculation of fluorescence molar absorption coefficient (ε)

[0090] Same as the fluorescence molar absorption coefficient ε obtained in Table 2 in Example 1.

[0091] 3.2 Calculate the average molecular weight (M 平均 )

[0092] In this case, under the same instrument and research conditions, taking cream cosmetic 1 as a sample, the following Figure 4 Shown liquid chromatogram, its average molecular weight calculating method is with embodiment 1, specifically following table 5:

[0093] Table 5 Nonylphenol polyoxyethylene ether (...

Embodiment 3

[0100] Example 3 Nonylphenol polyoxyethylene ether (NP) in cream cosmetic sample 2 n EO) and octylphenol ethoxylates (OP n Determination of EO) content

[0101] 1. Preparation of samples

[0102] Same as Example 1

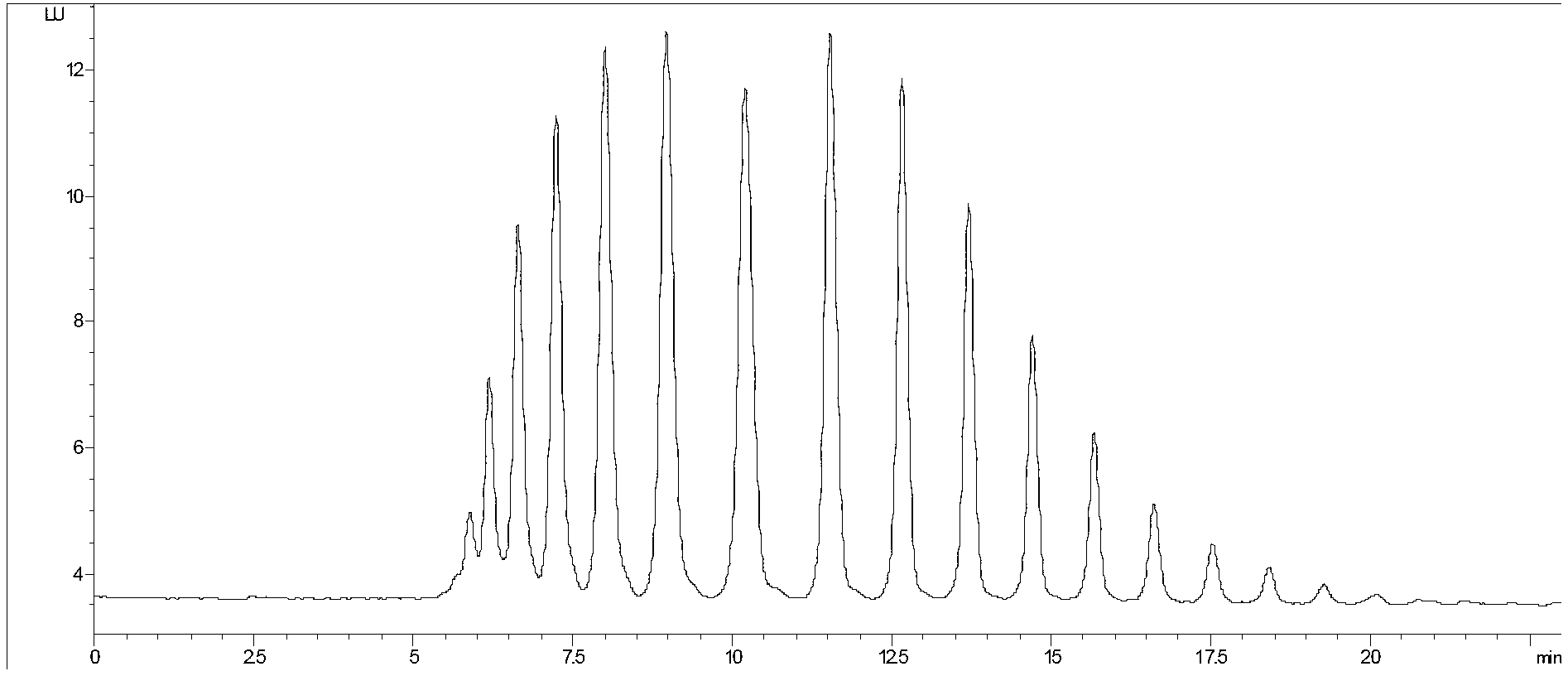

[0103] 2. Determination by HPLC

[0104] With embodiment 1, obtain test sample chromatogram, as Figure 5 Shown, and judging from the peak time that the added substance is OPEO.

[0105] 3. Quantitative calculation

[0106] 3.1 Calculation of fluorescence molar absorption coefficient (ε)

[0107] Same as the fluorescence molar absorption coefficient ε obtained in Table 2 in Example 1.

[0108] 3.2 Calculate the average molecular weight (M 平均 )

[0109] In this case, under the same instrument and research conditions, taking cream cosmetic 2 as a sample, the following Figure 5 Shown liquid chromatogram, its average molecular weight calculating method is the same as embodiment 1, specifically following table 6:

[0110] Table 6 Octylphenol polyoxyethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com