Vision monitoring method for full encapsulation process

A whole-process, visual technology, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problems of discarded finished products, increased scrap rate of finished products, and difficulty in quality monitoring, etc., and achieve comprehensive effects of controlling scrap rate and quality monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

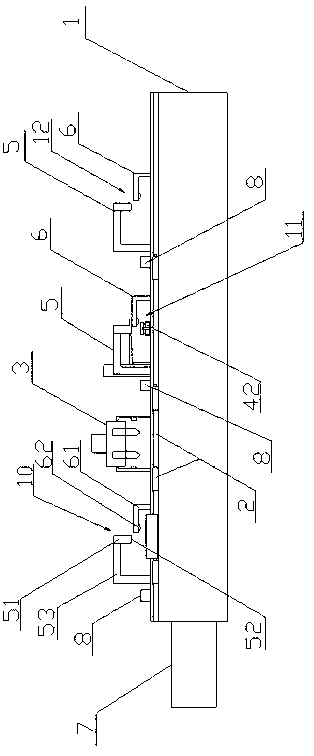

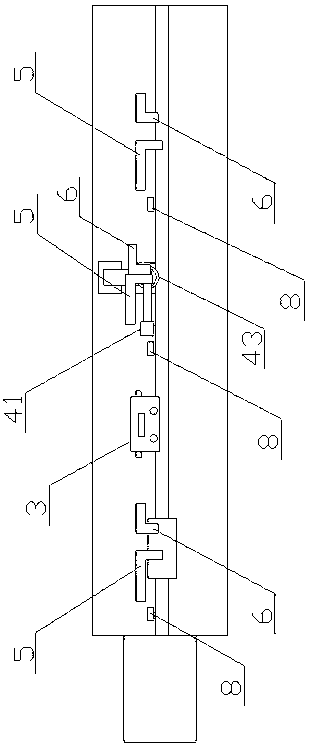

[0036] In this embodiment, the packaging of sensors is taken as an example for introduction. combine figure 1 , figure 2 As shown, the encapsulation whole process visual monitoring method in this embodiment includes the following steps:

[0037] 1) Three camera mechanisms 5 are installed on the three packaging stations of the packaging equipment, and the three camera mechanisms 5 are then electrically connected to an industrial computer 7. The electrical connection can be connected through USB lines, communication lines, etc. Three light sources 6 are also arranged corresponding to the three camera mechanisms 5;

[0038] 2) Set a template picture without defects in the industrial computer 7 for comparison with the actual picture;

[0039] 3) The light source 6 shines on the materials on the station, and the camera mechanism 5 takes pictures of the materials on the station, and the images obtained from the photos are input into the industrial computer 7 and compared with th...

Embodiment 2

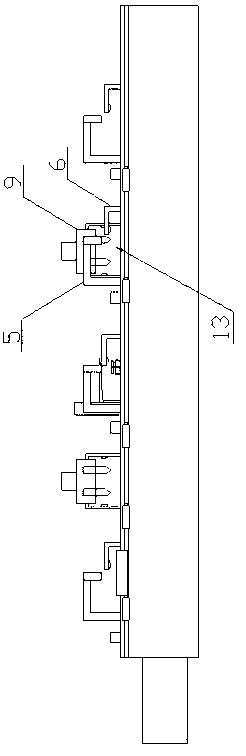

[0059] This embodiment is introduced by taking the packaging process of diodes as an example. It is roughly the same as the content of embodiment 1, the difference is: as image 3 , Figure 4 As shown, it also includes a second dispensing mechanism 9 for dispensing glue to the chip, which constitutes a fourth station 13, which is arranged between the second station and the third station. This fourth station 13 is also equipped with a camera mechanism 5 and a light source 6 . An alarm module 8 may also be included.

[0060] When monitoring the above-mentioned fourth station 13:

[0061] 2) In the step, a picture of a material that has been dispensed with glue on the grain without defects is set in the industrial computer 7;

[0062] In step 3), the camera mechanism takes pictures of the material pictures on the third station 14, and the images obtained from the pictures are input into the industrial computer for comparison with the predetermined material pictures.

[0063]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com