Straightening machine for electronic component lead

A technology of electronic components and straightening machines, which is applied in the field of electronic component lead wire straightening machines, can solve problems such as difficult quality control, lead wire stretching deformation, looseness, etc., and achieves the goal of improving production efficiency, avoiding pulling damage, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

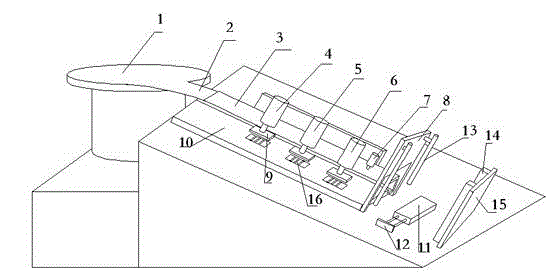

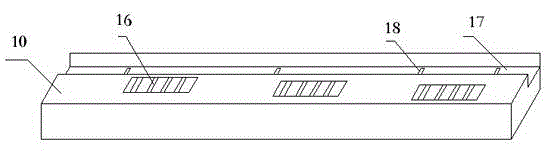

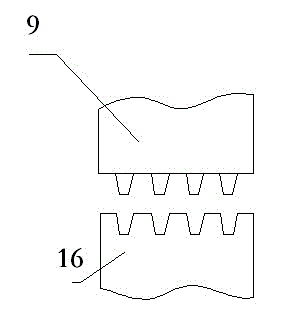

[0020] Such as figure 1 , 2 , 3 shows, a kind of electronic component lead wire straightening machine of the present invention, comprises controller, power unit, vibrating plate 1 and workbench, and vibrating plate 1 outlet is connected with transport piece flat rail 2. The electronic components are placed in the vibrating plate 1, and the electronic components are arranged and output from the flat rail 2 during the vibration process. The inner side of the workbench is horizontally provided with a chute 17 that is smoothly transitioned to the end of the conveying flat rail 2 . Generally, the bottom of the workbench is supported by a slope frame. The outside of the workbench is provided with a lead wire straightening platform 10, and a straightening mechanism is arranged on the lead wire straightening platform 10. A lifting lead lug 9 that can be clamped and matched with the lead wire slot is provided; a component stop mechanism that can stop the electronic component lead wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com