A kind of thin strip continuous casting free looper control method and device

A control method and looper technology, which are applied in the field of free looper control methods and devices for thin strip continuous casting, can solve problems such as cracks in overcasting strips, and achieve the benefits of looper control, accurate looper shape and position, and process adaptability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

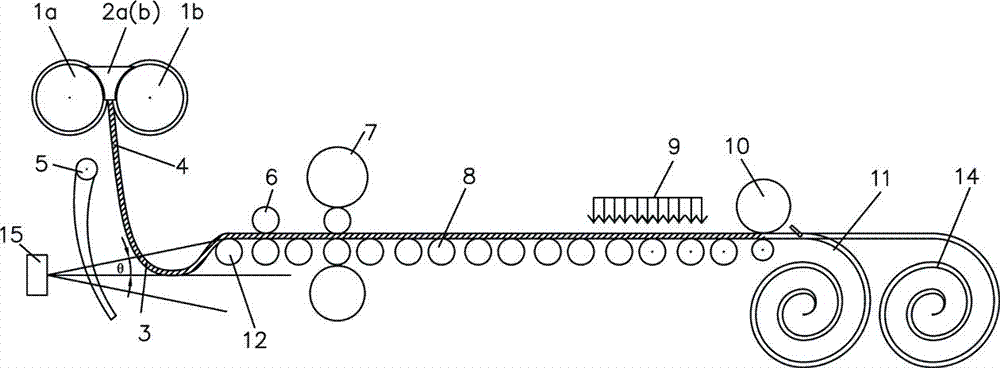

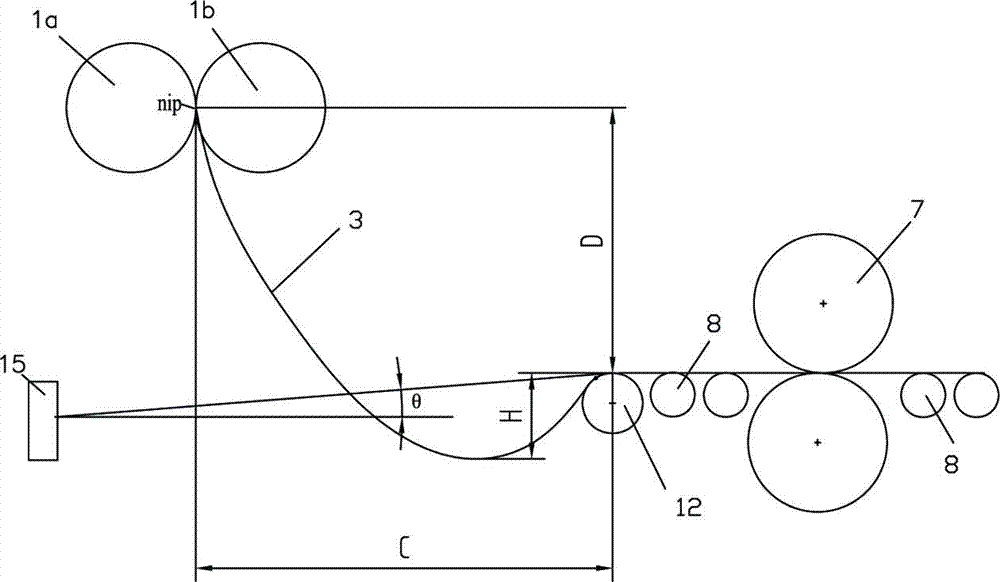

[0054] see Figure 2 to Figure 7 , a thin strip continuous casting free looper control method of the present invention comprises the following steps:

[0055] a. At the initial stage of casting, the swinging guide plate 5 is lifted and located at its upper working position, and the casting belt looper guide device 12 is lifted to keep the conveying height of the casting belt formed on the upper surface of all the rollers consistent with the height of the subsequent conveying roller table, The upper surface of the swing guide plate 5 borders on the most end roller surface of the cast belt looper guide 12, and keeps the height of the joint of the two consistent, as image 3 , the casting belt can be smoothly conveyed to the follow-up conveying roller table 8 through the swing guide plate and the loop guide device.

[0056] b. After the casting belt enters the follow-up process, the swing guide plate 5 swings to its lower working position. At this time, the cast strip loop guid...

Embodiment 2

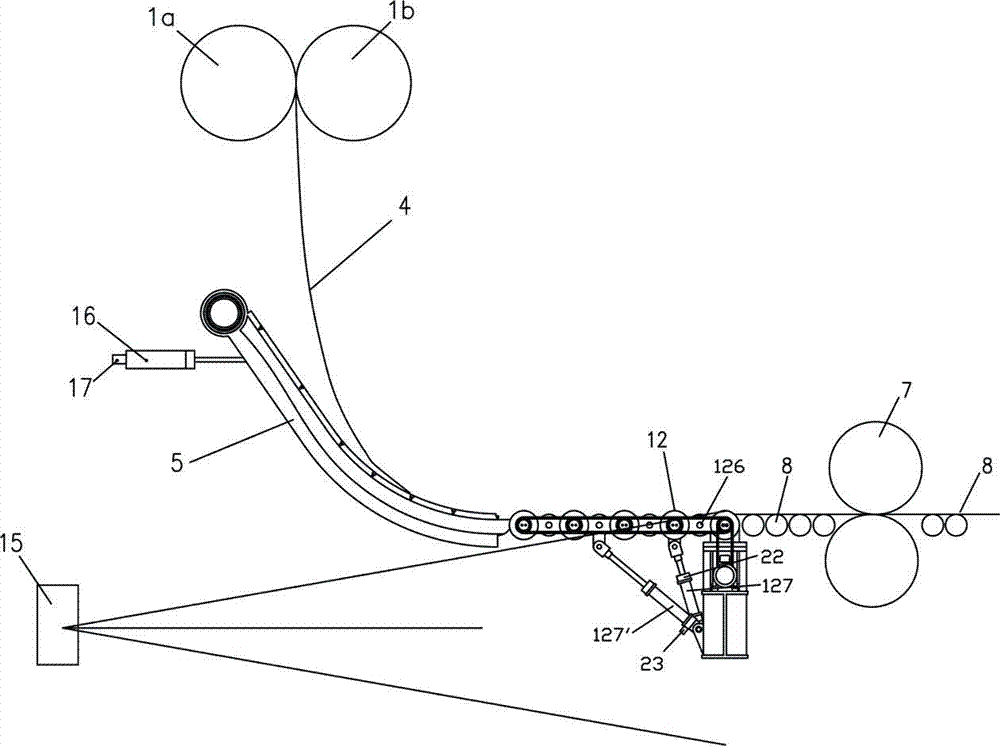

[0069] see Figure 8 , the thin strip continuous casting free looper control method of the present invention comprises the following steps:

[0070] a. The casting belt establishes a looper, and the swing guide plate 5 swings to its lower working position under the drive of the hydraulic cylinder 16. The specific working position is detected by the displacement sensor 17 and fed back to the looper guide controller 18, which is passed through the servo valve. 19 implement the stroke control to the hydraulic cylinder.

[0071] b. At the same time, the looper detection device 15 monitors the height of the looper in real time, and outputs the detection value to the looper guide controller 18, and the looper position data detected on the power generation motors 126a-126d on the looper guide roller group 12 is output To the looper guide controller 18, the latter calculates the casting belt guide bending radius r according to the parameters such as the current casting belt looper he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com