Imprinting equipment

A technology of equipment and transmission disc, applied in the field of engraving equipment, can solve the problems of low production efficiency, small transmission chain pitch, complex structure, etc., and achieve the effect of improving engraving efficiency, wide and solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

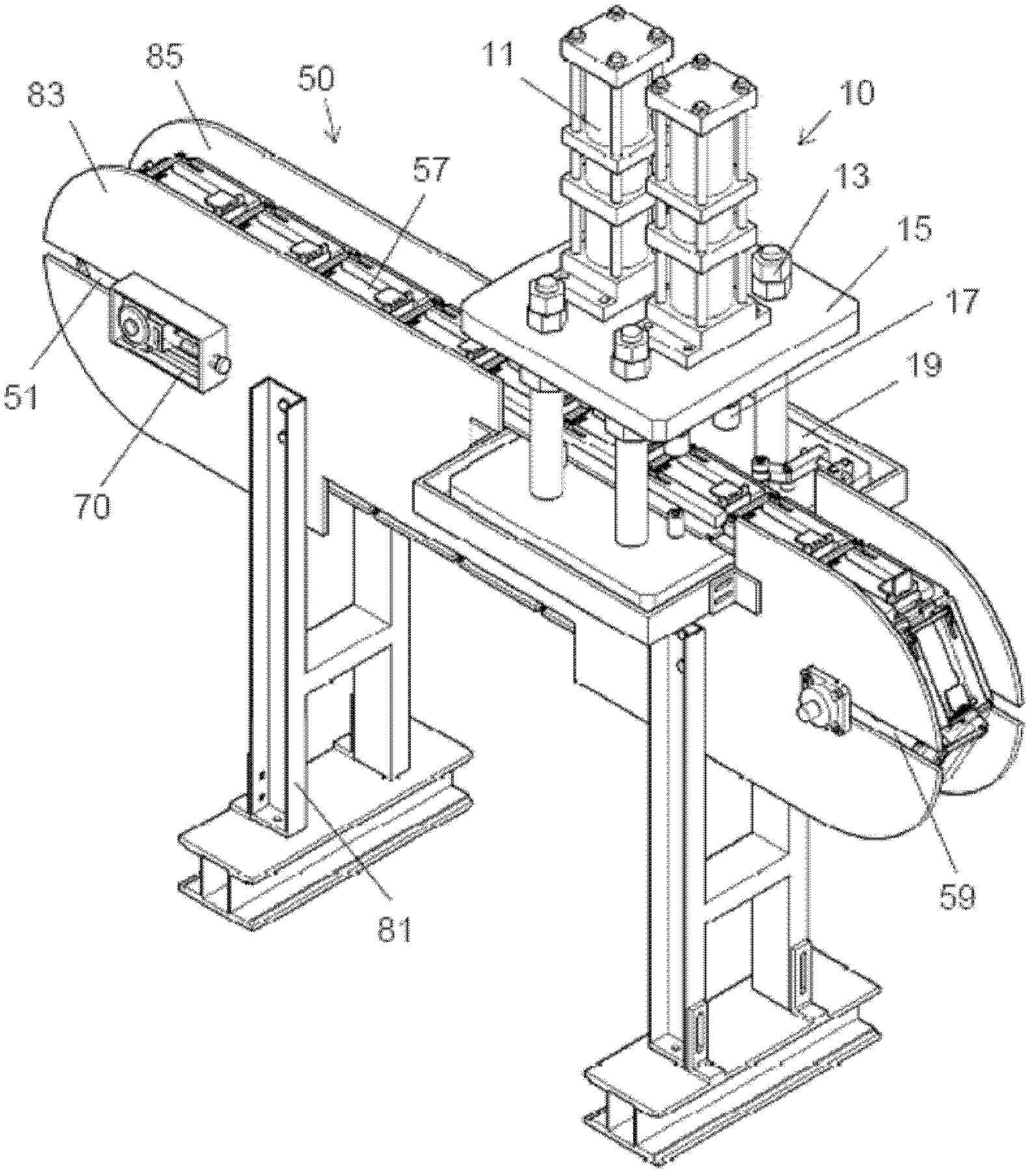

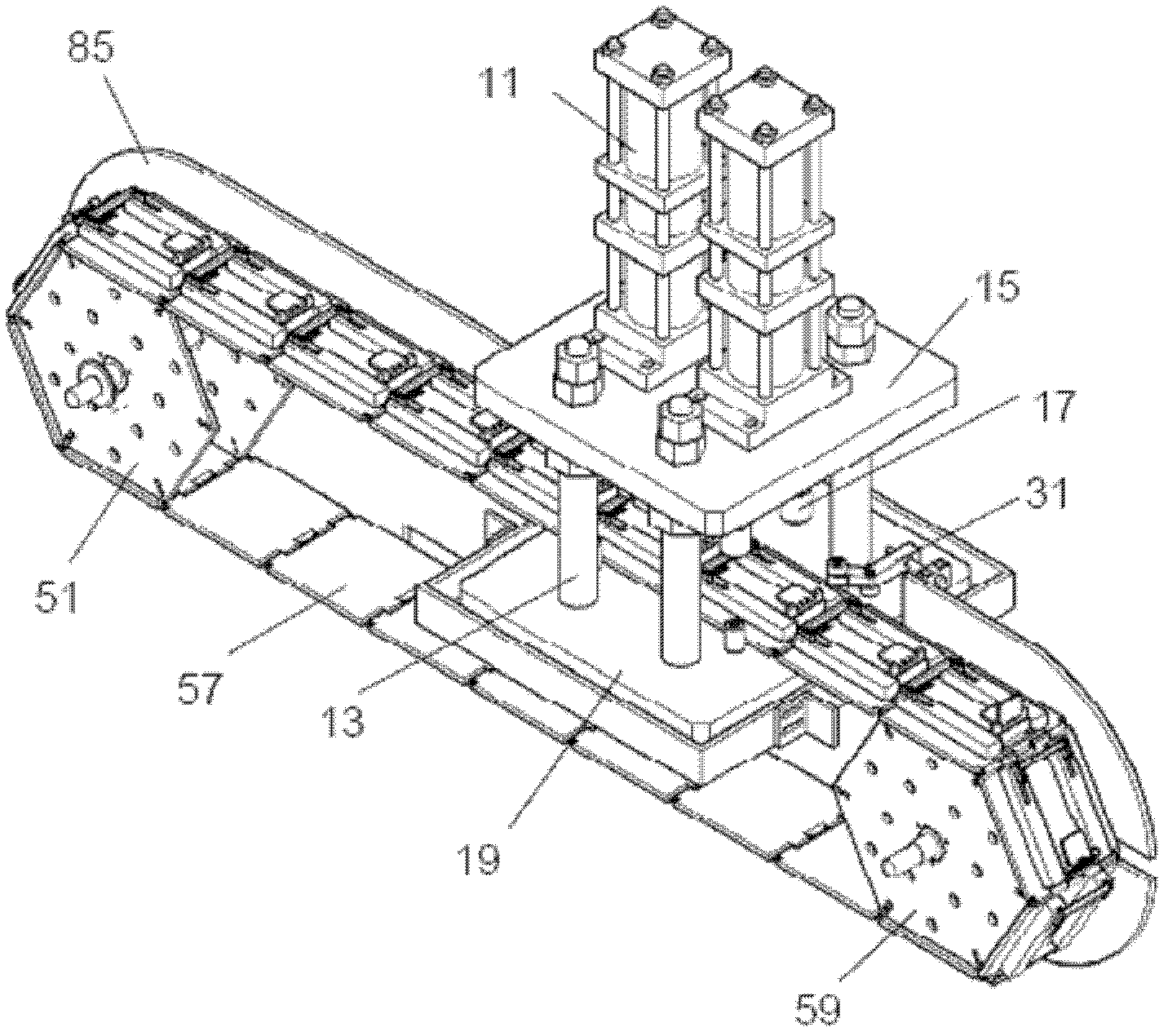

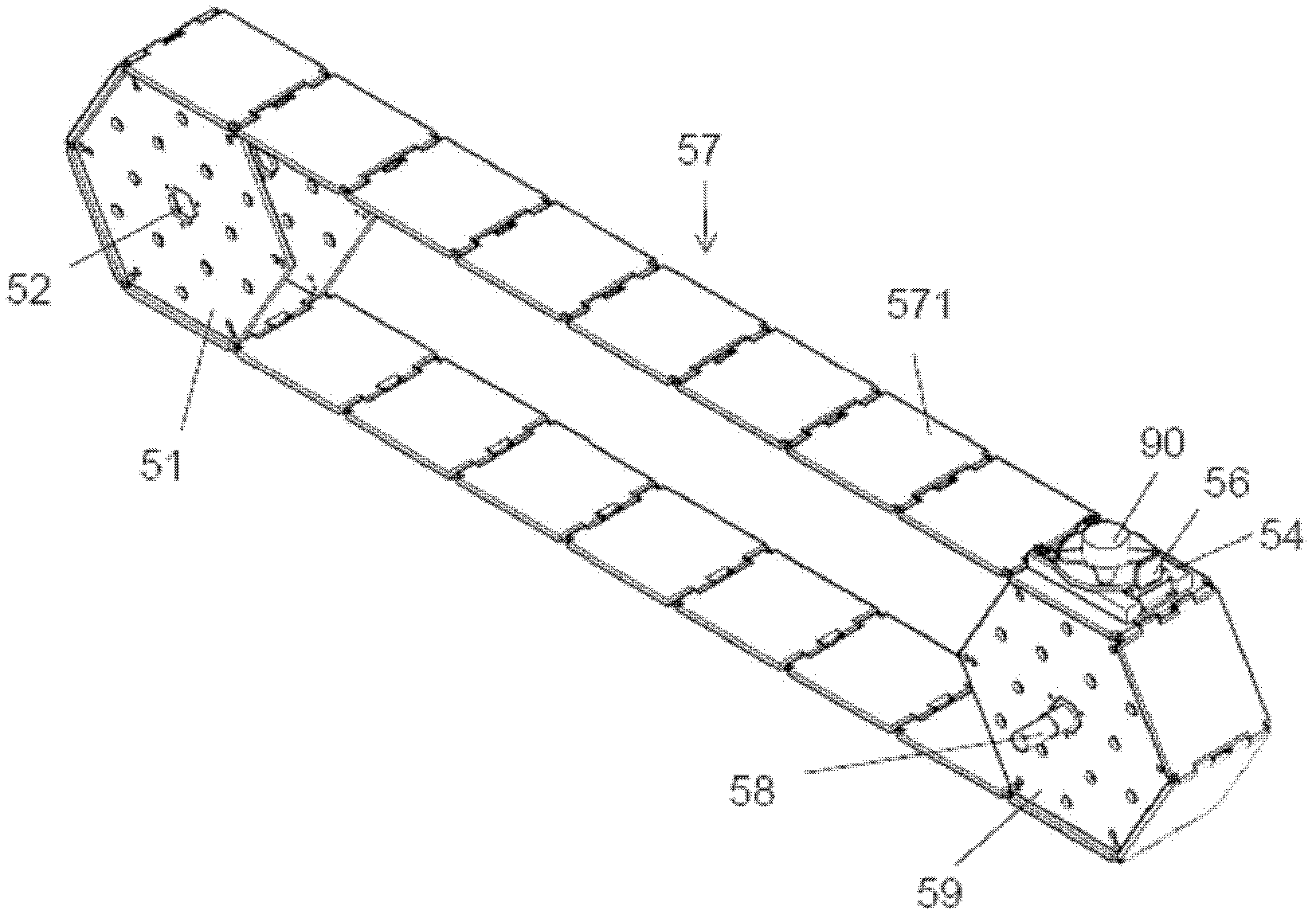

[0024] Such as figure 1 , Figure 5 As shown, a preferred embodiment of the present invention is a device for marking by stamping, which is mainly composed of a stamping mechanism 10 , a transmission mechanism 50 and a control system 30 . Transfer mechanism 50 will be engraved workpiece 90 (referring to image 3 ) is transferred to the station where the punching mechanism 10 is located, and punching can be directly carried out without going through another feeding mechanism. The control system 30 controls the synchronization of the stamping mechanism 10 and the transfer mechanism 50 through the computer 32 . The stamping mechanism 10 and the transmission mechanism 50 are installed on a frame composed of a bracket 81 , a first baffle 83 and a second baffle 85 .

[0025] Such as figure 1 , figure 2 As shown, the stamping mechanism 10 includes two cylinders 11, an upper template 15 and a lower template 19 connected by four pillars 13, and two groups of punch assemblies 17 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com