Paper feeding positioning device and operating method thereof

A positioning device and paper feeding technology, applied in the direction of positioning objects, transportation and packaging, object supply, etc., can solve the problems of secondary paper offset, large space, paper offset, etc., to improve accuracy, reduce errors, and easily control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

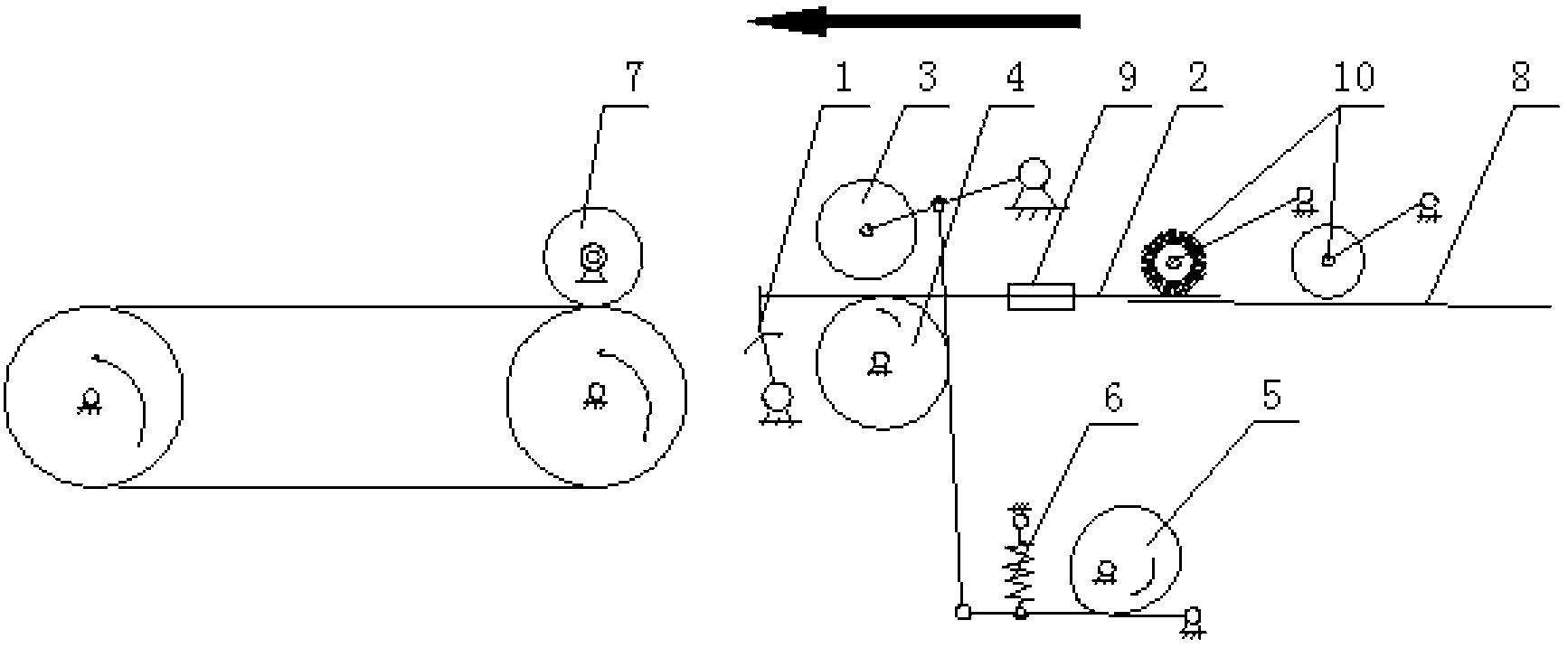

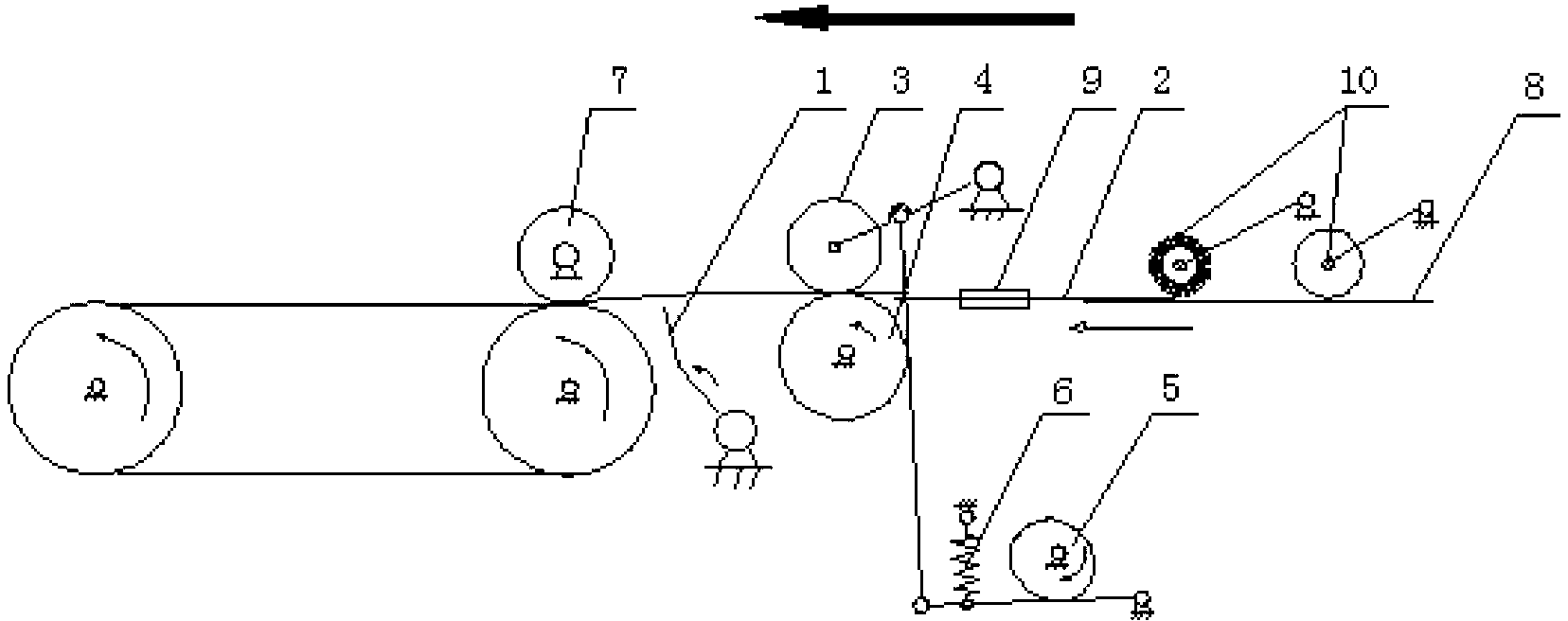

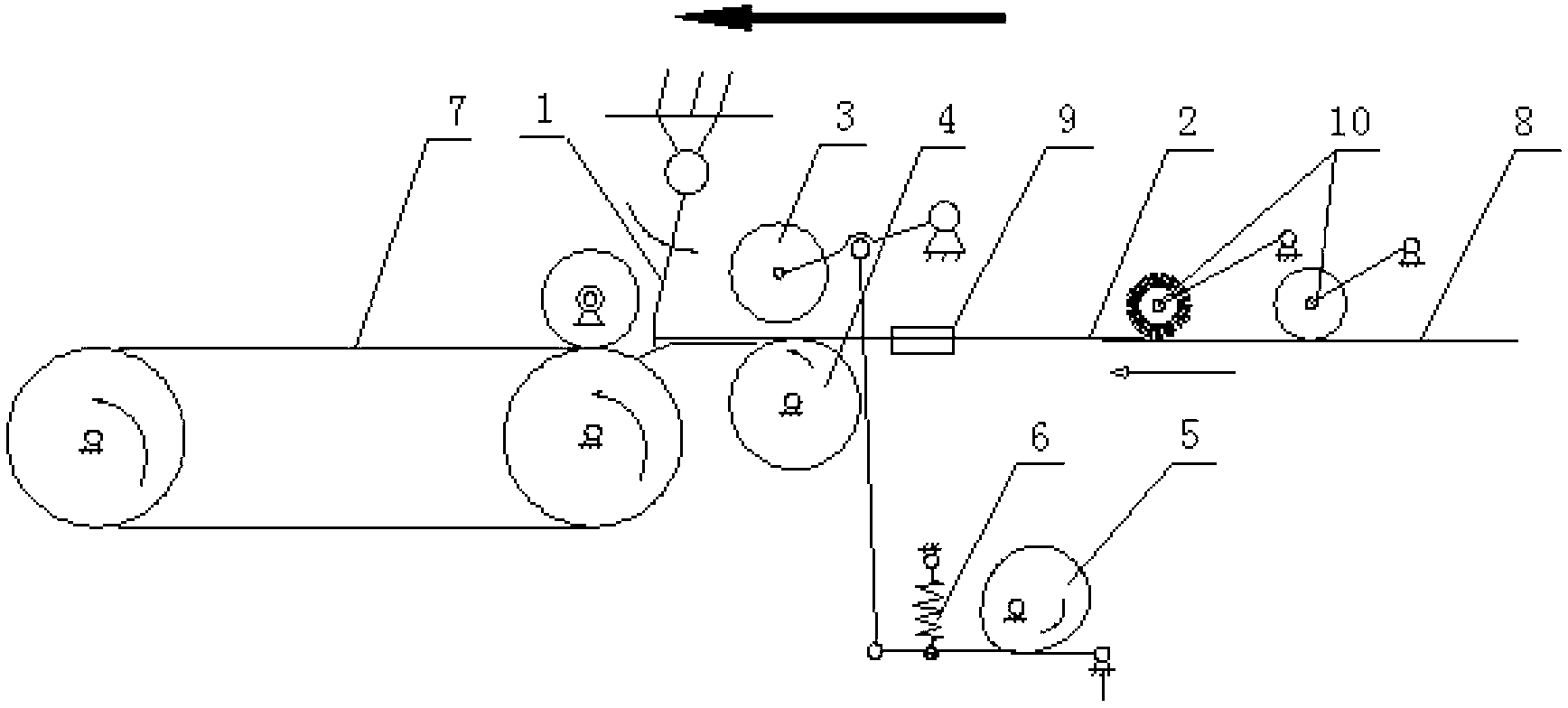

[0021] Embodiment: a kind of paper feeding positioning device (see image 3 , Figure 4 ), including a front gauge 1, a press roller 3, a paper feed roller 4, a paper feed platform 8 and a side gauge 9;

[0022] The front gauge 1 is connected to the servo motor that controls the up and down swing of the front gauge 1; in the positioning state, the front gauge 1 falls to perform front positioning of the paper, and the pressure roller 3 is lifted (see image 3 ); in the paper feeding state, the front gauge 1 lifts up, the pressure roller 3 falls and the paper feeding roller 4 rolls and rubs to feed the paper (see Figure 4 ).

[0023] The press wheel 3 is connected to the cam 5 through a connecting rod; the cam 5 is connected to a power source, and the cam 5 rotates to control the up and down movement of the press wheel 3; one end of the connecting rod is fixed to the spring 6, and the other end is fixed on the frame above; the side gauge 9 is located on the paper delivery pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com