Treatment method and treatment apparatus for wastewater of daily chemicals

A treatment method, waste water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of large reactor volume, slow anaerobic degradation speed, and limited biochemical methods Application and other issues to achieve the effect of improving biodegradability and improving effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

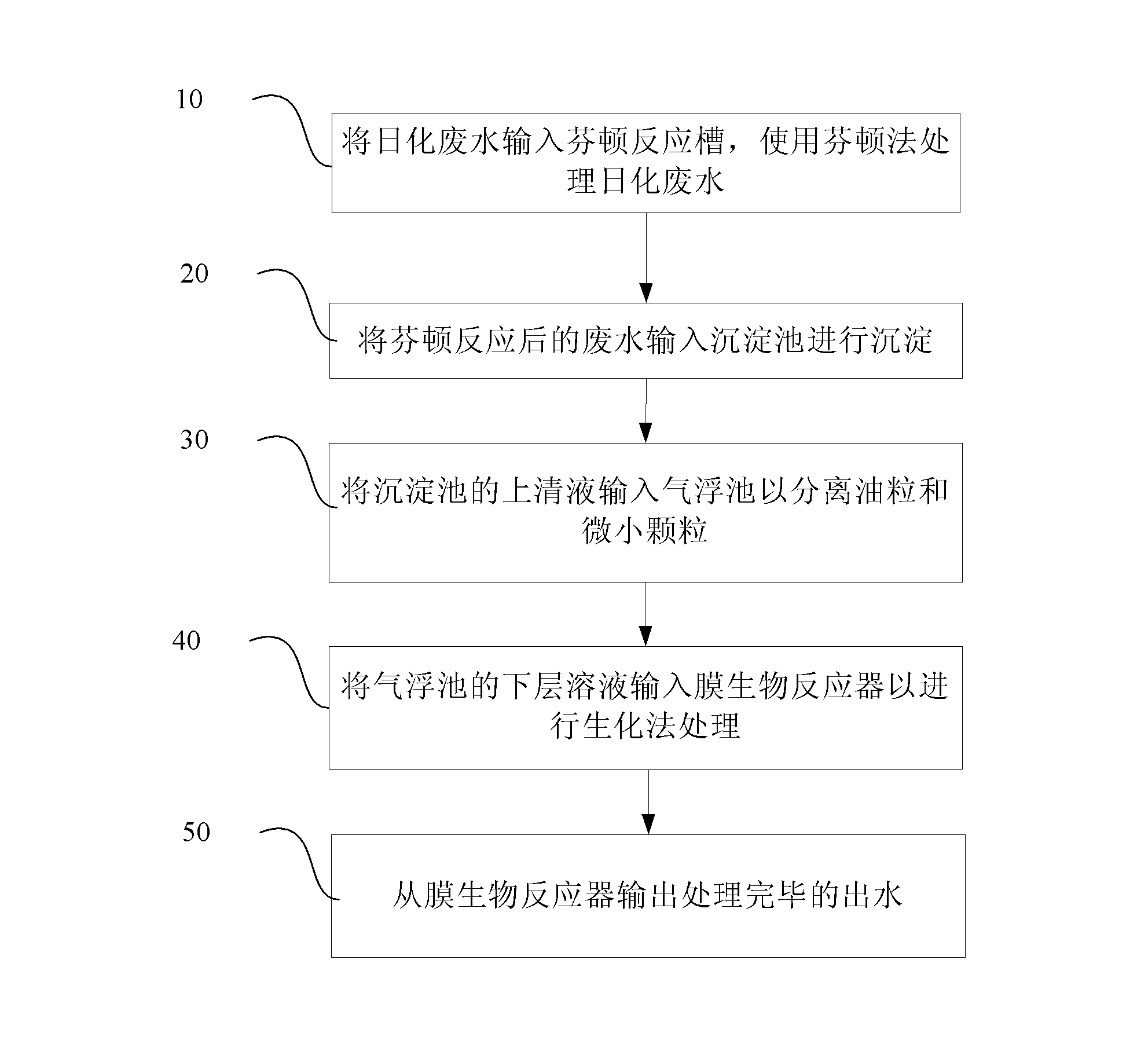

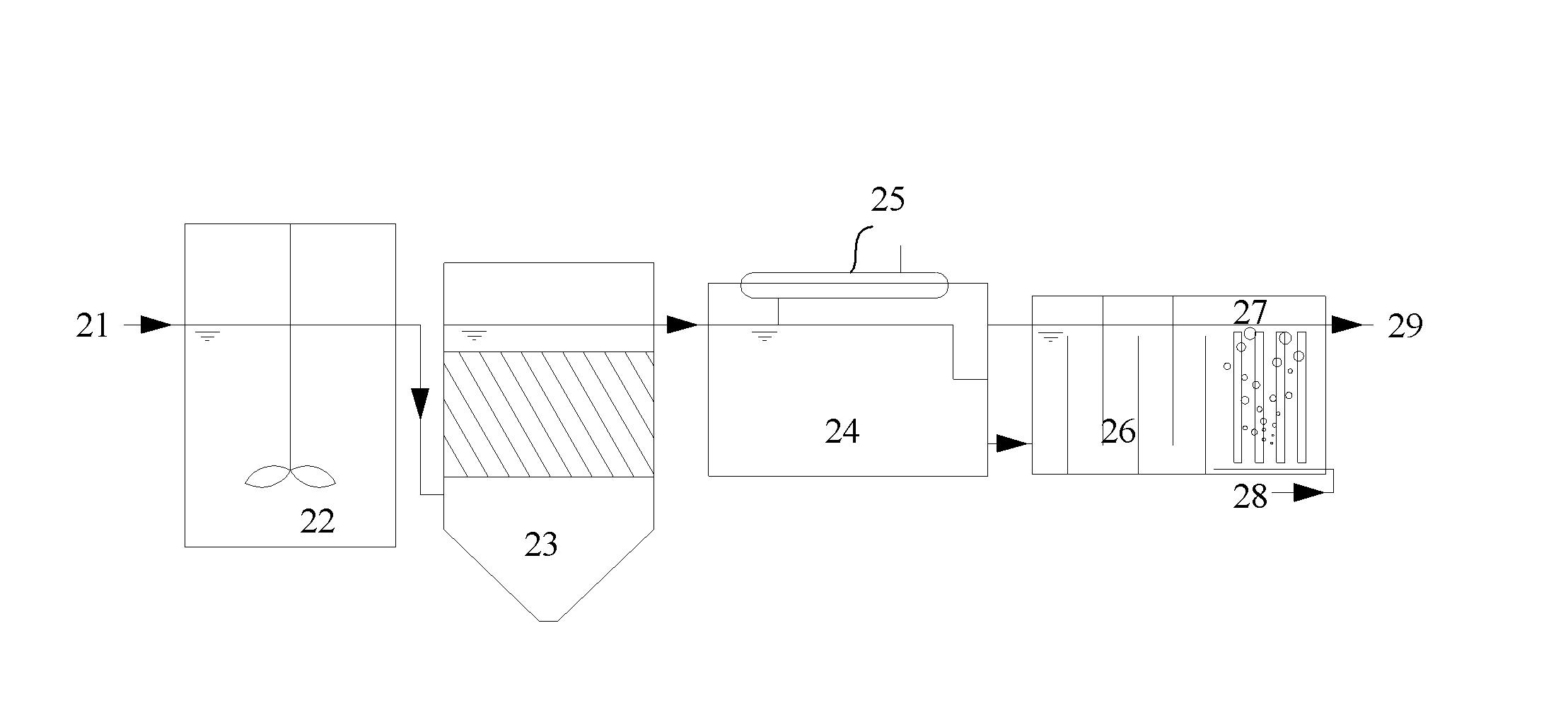

[0021] The following examples of the present invention describe the methods that can effectively treat pollutants such as COD, surfactants, and petroleum in daily chemical wastewater. Embodiments of the present invention will be primarily based on biochemical methods. Biochemical method refers to the method of removing organic matter by biochemical method. It is a process in which microorganisms use organic matter in water as food, transform it into their own cells and generate energy to maintain life activities.

[0022] In the biochemical method, the membrane bioreactor can completely trap the microorganisms in the bioreactor, keep the concentration of microorganisms in the activated sludge system at a high level, and the reactor has a good response to various changes in the influent load. Excellent adaptability, impact load resistance, and stable high-quality effluent quality. Therefore, the membrane bioreactor is a better choice for the implementation of biochemical metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com