Conductive phenolic resin forming material

A phenolic resin and molding material technology, applied in the field of thermosetting molding compounds, can solve problems such as charge accumulation and trouble, and achieve the effects of high strength and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

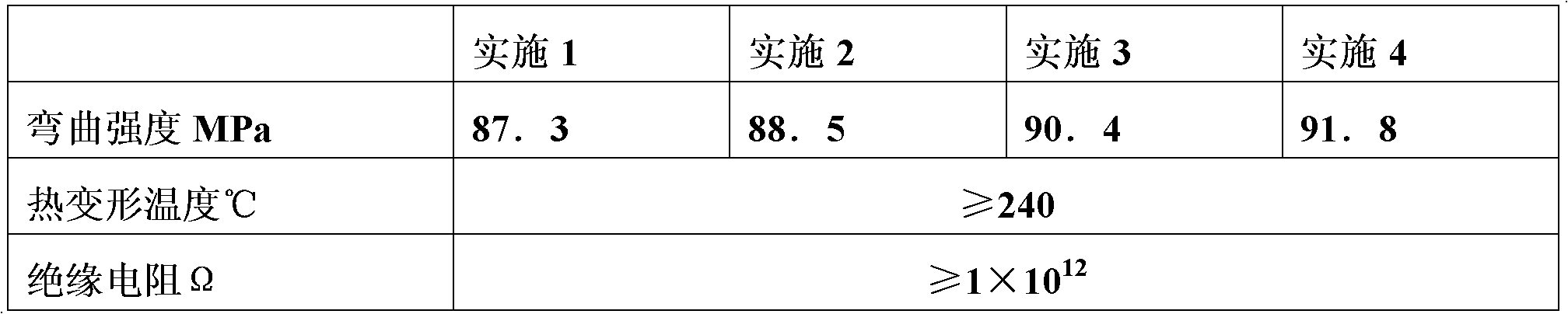

Examples

Embodiment 1

[0021] 36 parts of phenolic resin (produced by oxalic acid method);

[0022] 2.8 parts of hexamethylenetetramine;

[0023] 0.9 parts of zinc oxide;

[0024] 4.5 parts of conductive carbon black;

[0025] Lithium stearate 0.7 part;

[0026] Calcium carbonate 26 parts;

[0027] Glass fiber 16 parts.

[0028] During specific implementation, firstly, the above-mentioned raw materials are accurately weighed sequentially, then mixed uniformly, transferred to an open mill and heated for 6 minutes, then pulled, cooled, and pulverized to obtain the original color conductive phenolic resin molding material.

Embodiment 2

[0030] 37 parts of phenolic resin (produced by oxalic acid method);

[0031] 3.5 parts of hexamethylenetetramine;

[0032] 1.2 parts of zinc oxide;

[0033] 5.8 parts of conductive carbon black;

[0034] 1.0 parts of lithium stearate;

[0035] Calcium carbonate 28 parts;

[0036] 18 parts of glass fiber;

[0037] Carbon black 2 parts.

[0038] During specific implementation, firstly, the above-mentioned raw materials are accurately weighed in turn, then mixed uniformly, transferred to an open mill and heated for 6 minutes, then pulled, cooled, and pulverized to obtain a black conductive phenolic resin molding material.

Embodiment 3

[0040] 38 parts of phenolic resin (produced by oxalic acid method);

[0041] 3.8 parts of hexamethylenetetramine;

[0042] 1.3 parts of zinc oxide;

[0043] 6.9 parts of conductive carbon black;

[0044] Lithium stearate 1.3 parts;

[0045] Calcium carbonate 29 parts;

[0046] 19 parts of glass fiber;

[0047] Fast Yellow G 2.2 parts.

[0048] During specific implementation, firstly, the above-mentioned raw materials are accurately weighed in sequence, then mixed uniformly, transferred to an open mill and heated for 6 minutes, then pulled, cooled, and pulverized to obtain a yellow conductive phenolic resin molding material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com