Leaf Spring Assemblies

A technology of plate springs and components, which is applied in the direction of engine components, valve details, valve operation/release devices, etc., can solve problems such as shortened service life, poor sealing, and reduced accuracy of proportional valves, so as to improve service life and assembly Convenience and the effect of reducing hysteresis force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

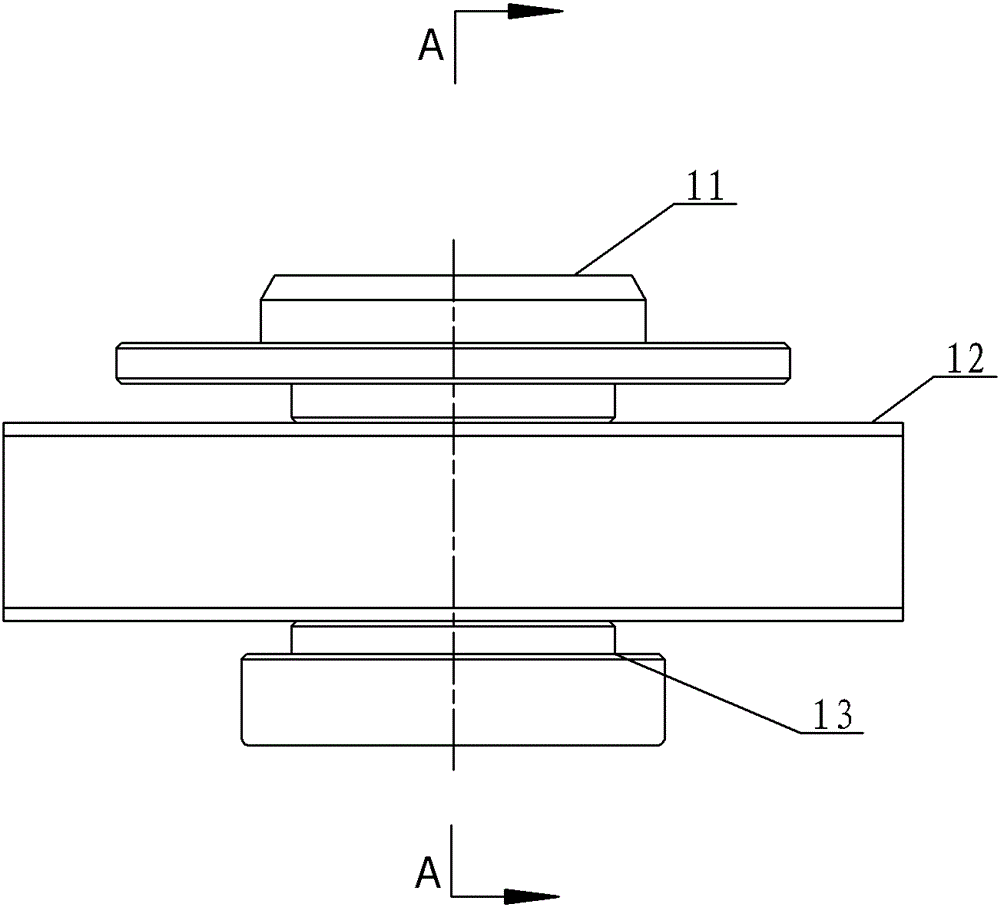

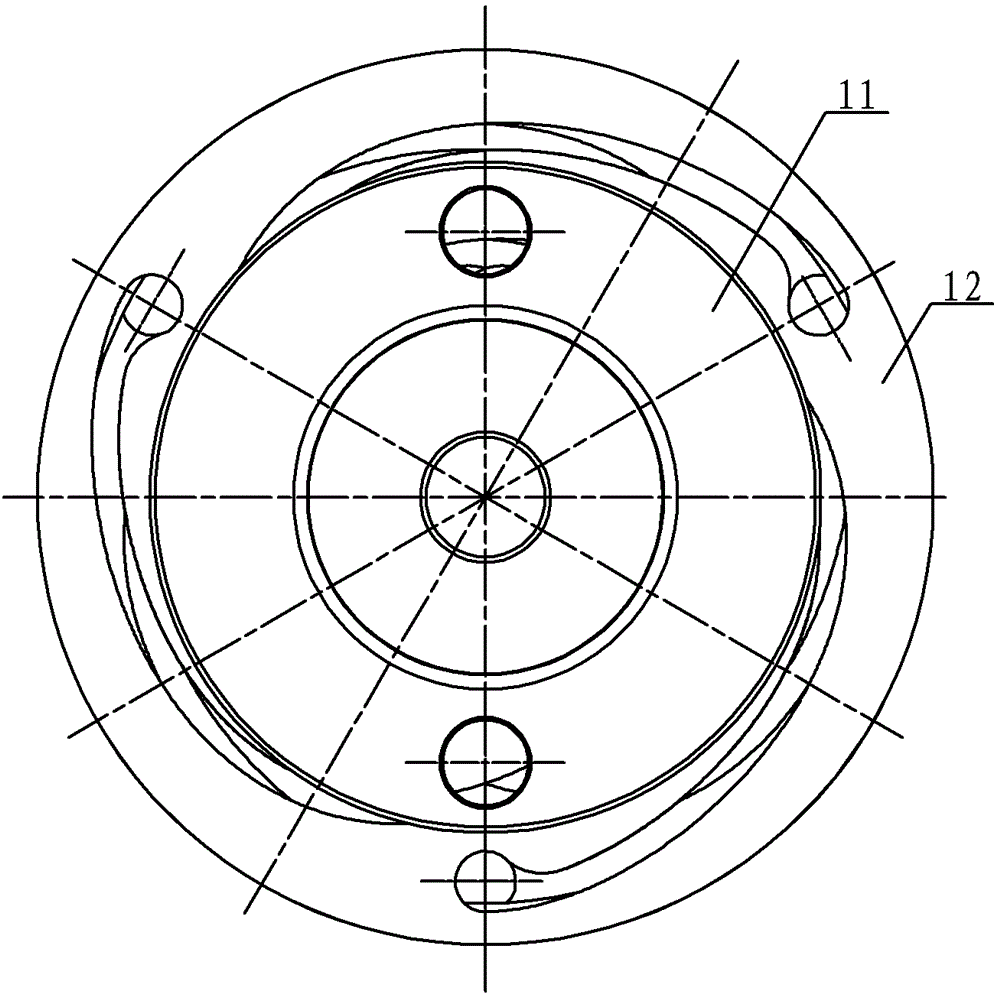

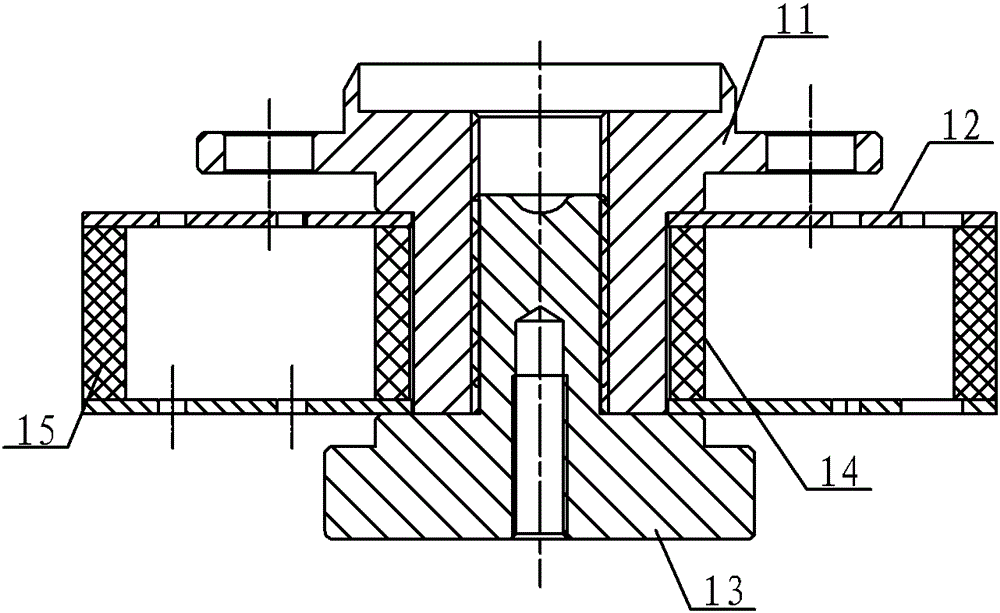

[0029] Such as Figure 1~5 In the shown embodiment, the plate spring assembly according to the present invention includes a lifting lower valve plate 13, a soft magnetic armature 11 is sleeved on the lifting lower valve plate 13, and two The plate springs 12 are parallel to each other. The plate springs 12 are circular, and there are several intermittent curved grooves on the plate springs 12. The spring assembly is used in the proportional valve, which can effectively avoid metal-to-metal contact. Contact eliminates mechanical friction, increases the service life of the proportional valve, reduces the hysteresis return force, and this design can make the pre-tightening force of the metal seal of the opening and closing part of the proportional valve more uniform, which is conducive to the realization of the metal seal and avoids The high requirements for verticality during assembly of the proportional valve reduce the difficulty of assembly.

[0030] In specific implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com