A micro-structure light guide plate and an edge type backlight module

A backlight module and microstructure technology, applied in optics, light guides, light sources, etc., can solve the problems of high printing point brightness, increase the cost of backlight modules, and high ink costs, and achieve improved production yield, good light guide effect, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

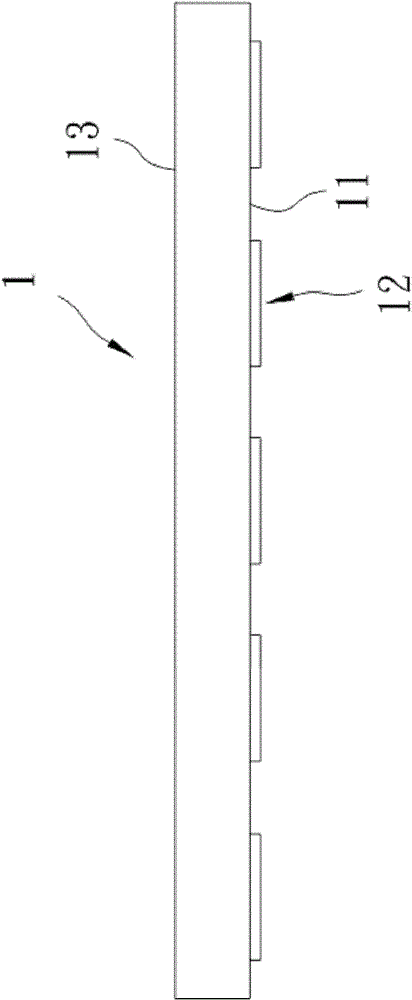

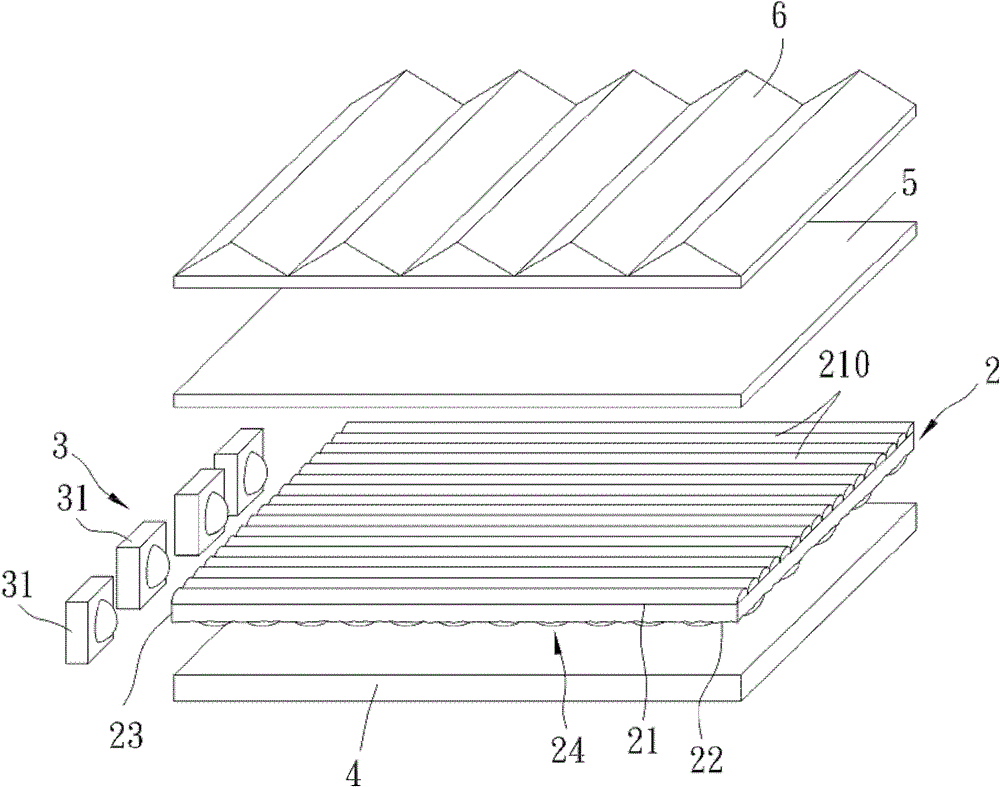

[0040] refer to figure 2 , 3 , the first preferred embodiment of the edge-lit backlight module of the present invention includes: a microstructured light guide plate 2 , a light source 3 , a reflection plate 4 , a diffusion film 5 , and a prism sheet 6 .

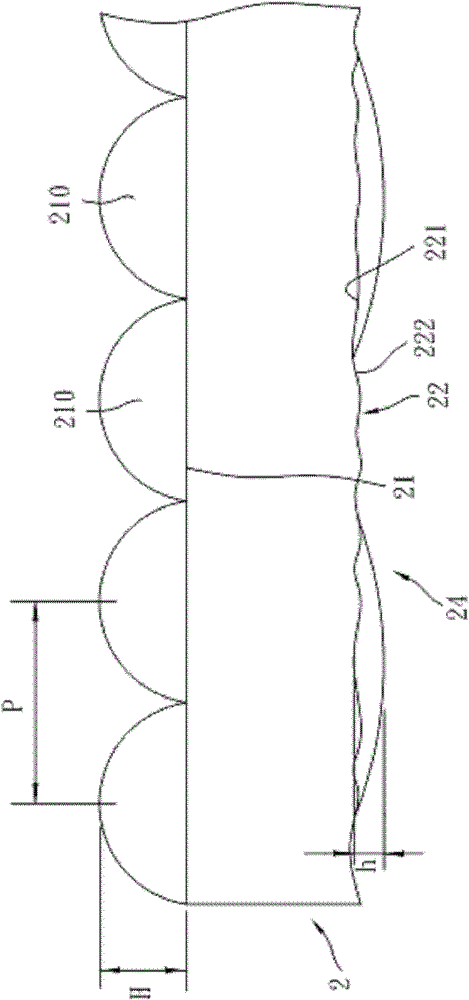

[0041] The microstructured light guide plate 2 includes: a light-emitting surface 21, a rough inner surface 22 located on the opposite side of the light-emitting surface 21, a light-incident surface 23 connected to one side of the light-emitting surface 21 and the inner surface 22, and a light-incident surface 23 located on the inner surface 22. 24 on the printed structure. Wherein, the light-emitting surface 21 has a plurality of columnar microstructures 210 extending in the longitudinal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com