Gas-barrier laminate film

A laminated film and gas-barrier technology, applied in the field of gas-barrier laminated film and its manufacture, can solve the problems of insufficient performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] Using a biaxially oriented polyethylene naphthalate film (manufactured by DuPont Teijin, "Q51C12") with a width of 1.2 m, a length of 12000 m, and a thickness of 12 μm as a base material film, the corona-treated surface was coated with an isocyanate compound ( "CORONATE L" manufactured by Nippon Polyurethane Industry) and saturated polyester ("BYRON300" manufactured by Toyobo, number average molecular weight 23,000) were mixed at a mass ratio of 1:1 and dried to form a bottom layer with a thickness of 100nm Adhesion layer.

[0119] Next, using a vacuum evaporation apparatus at 2 x 10 -3 SiO was evaporated by high-frequency heating under a vacuum of Pa, and a vacuum-evaporated film (PVD film) of SiOx with a thickness of 40 nm was formed on the bottom adhesion-promoting layer. Next, in the same vacuum evaporation device, without returning the pressure to atmospheric pressure, HMDSN (hexamethyldisilazane), nitrogen gas and argon gas were introduced at a molar ratio of 1:7...

Embodiment 2

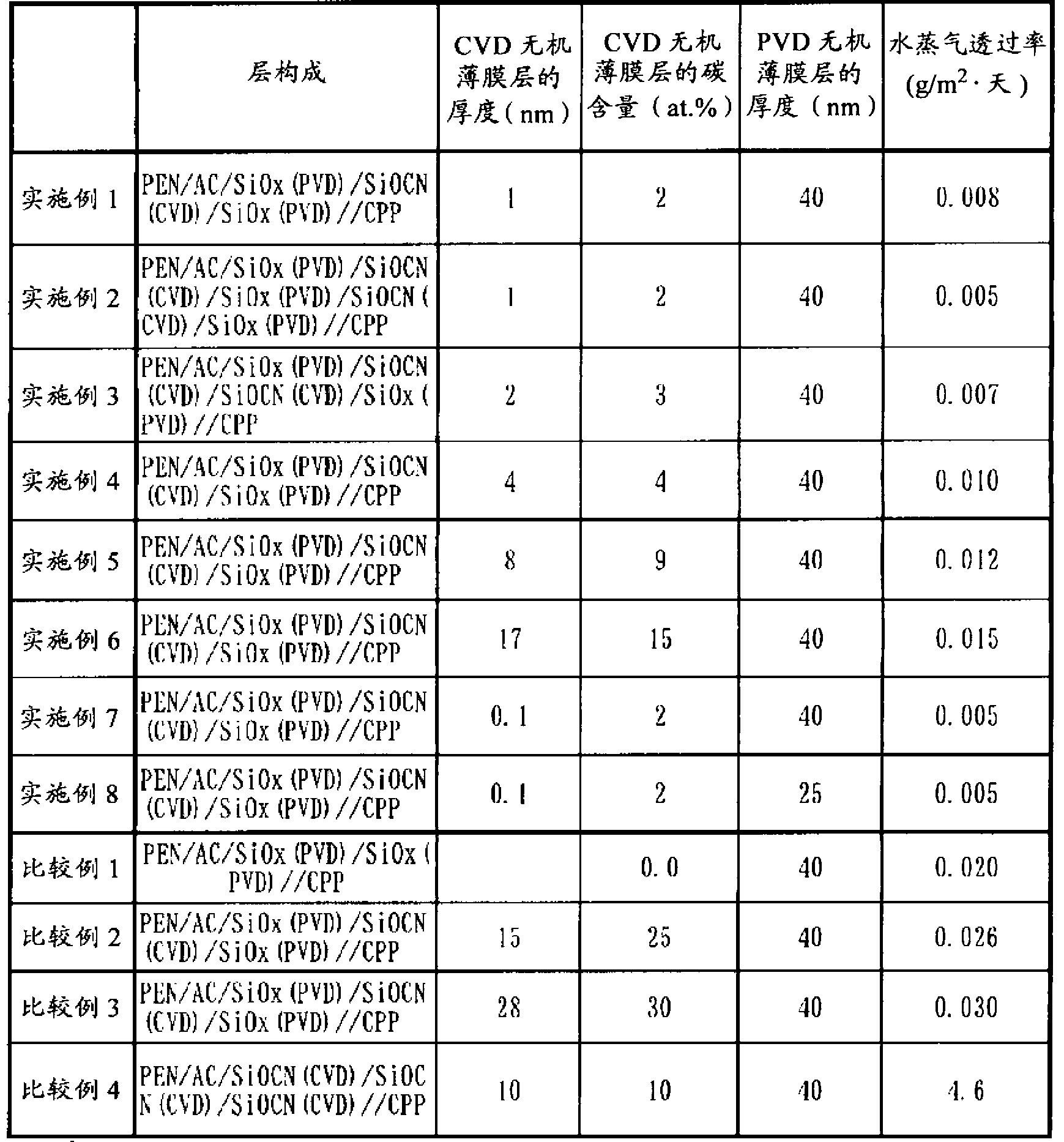

[0122] A laminated film was produced in the same manner except that the CVD inorganic thin film layer and the vacuum evaporated film layer (PVD inorganic thin film layer) in Example 1 were sequentially formed into one layer under the same conditions as in Example 1. The above-mentioned evaluation was performed on the obtained laminated film. The results are shown in Table 1.

Embodiment 3

[0124] A laminated film was produced in the same manner except that the formation of the CVD inorganic thin film layer in Example 1 was repeated twice under the same conditions as in Example 1 so that the CVD inorganic thin film layer had a two-layer structure. The above-mentioned evaluation was performed on the obtained laminated film. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com