Starter solenoid with spool for retaining coils

A technology of solenoids, bobbins, applied in the field of solenoids for starter motor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

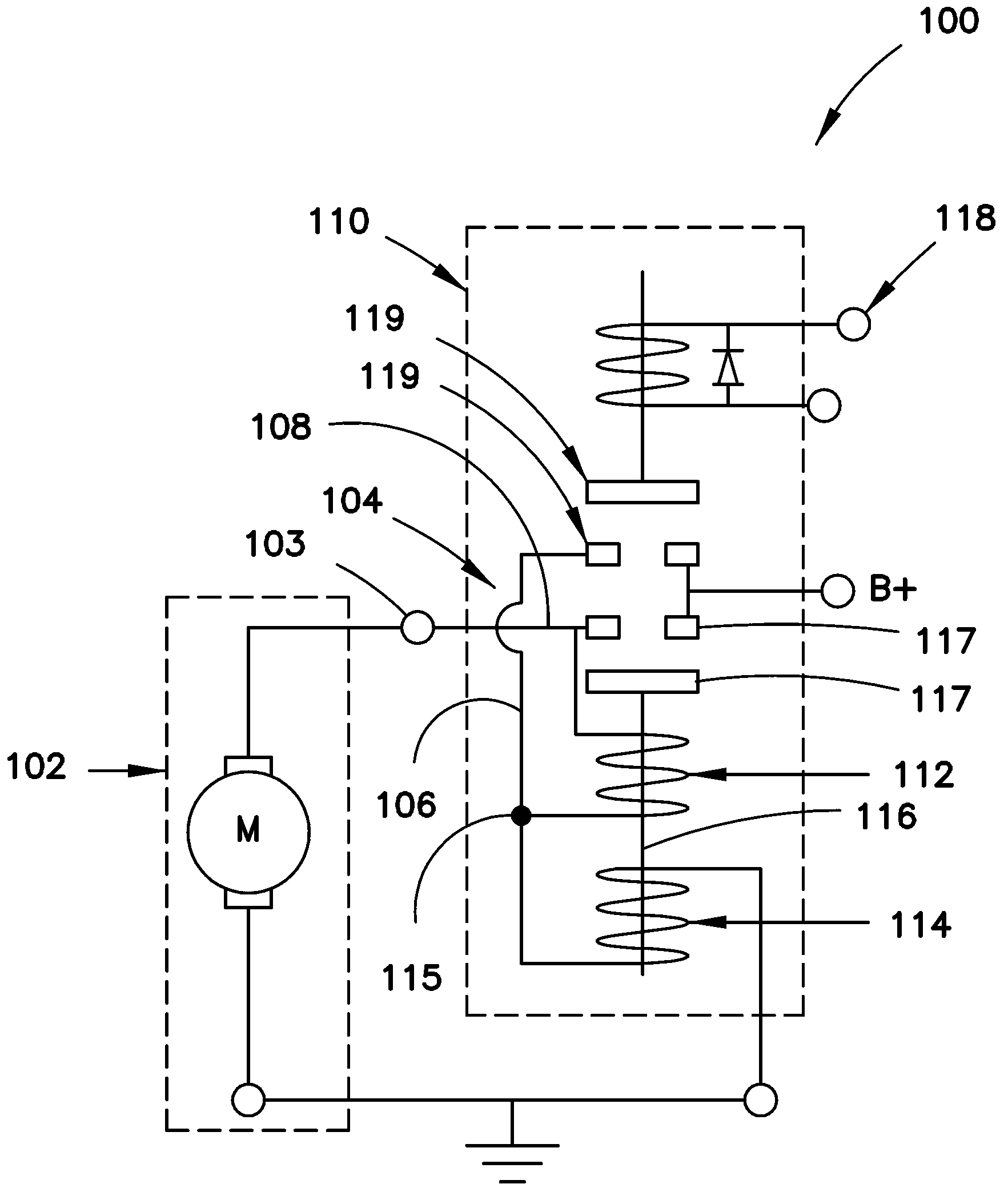

[0032] Overall starter arrangement

[0033] refer to figure 1 , in at least one embodiment, a vehicle starter 100 includes an electric motor 102 and a solenoid 110 . Although not in figure 1 shown in, with reference to the above Figure 15 Similar to the conventional starter assembly 200 described, the starter 100 also includes a drive mechanism and a pinion. exist figure 1 The electric motor 102 in the embodiment of the present invention is positioned in a motor circuit 104 configured to connect the electric motor to a vehicle battery (not shown) via a B+ terminal. A solenoid 110 is positioned in the motor circuit 104 to facilitate connecting the motor to the vehicle battery. The solenoid includes a pull coil 112 , a hold coil 114 , a push rod 116 and an ignition switch 118 .

[0034] figure 1 The motor circuit 104 includes a first current path 106 and a second current path 108 configured to provide electrical energy to the motor 102 . The first current path 106 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com