Toner, method for producing the toner, and image forming method

A technology of toner and release agent, applied in the field of toner, can solve problems such as large temperature and change, and achieve the effects of less pollution, excellent release property, and wide fixing temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

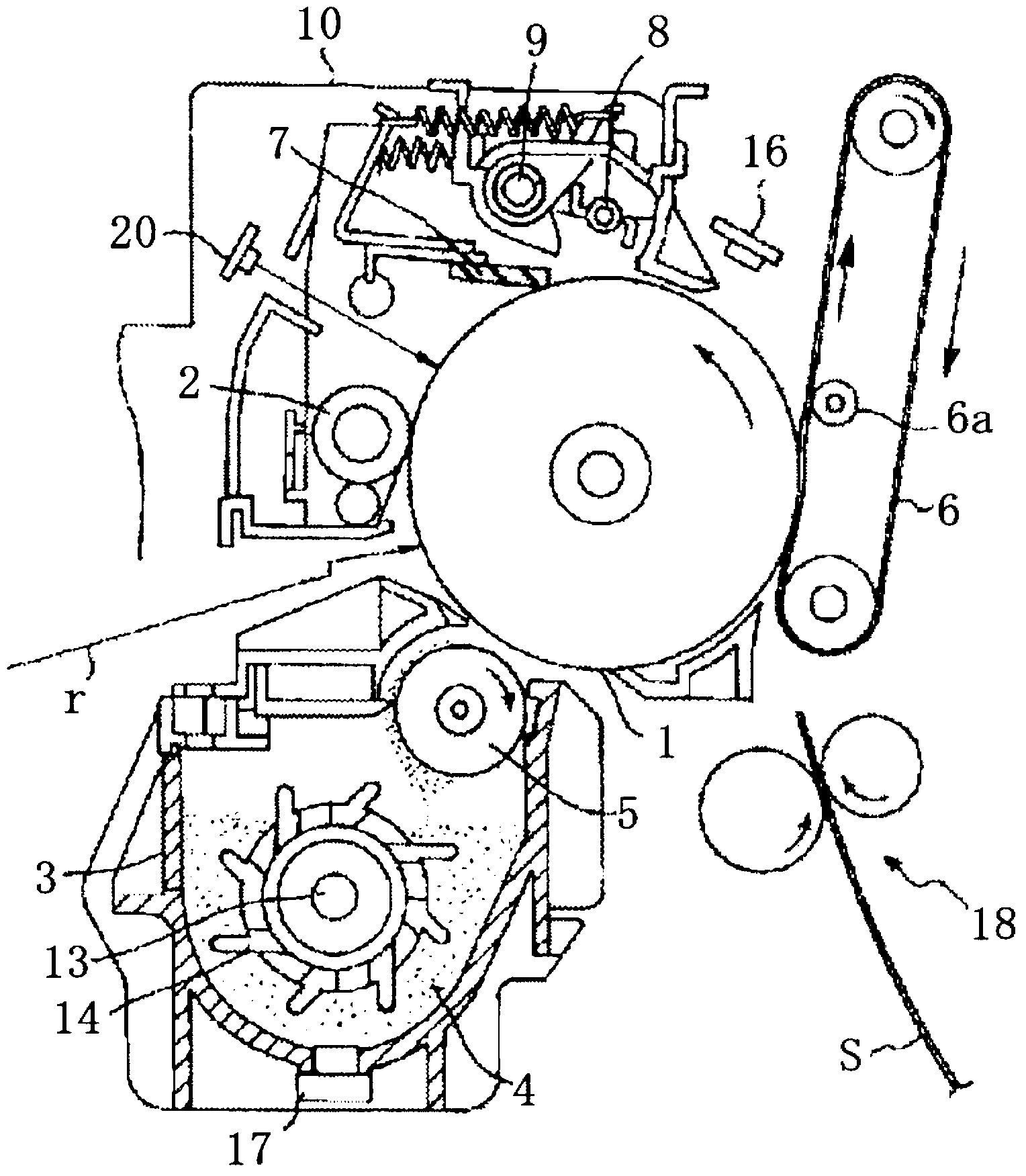

Method used

Image

Examples

Embodiment 1

[0427] [Manufacture of the toner of Example 1]

[0428]

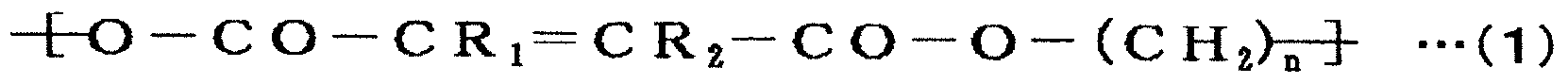

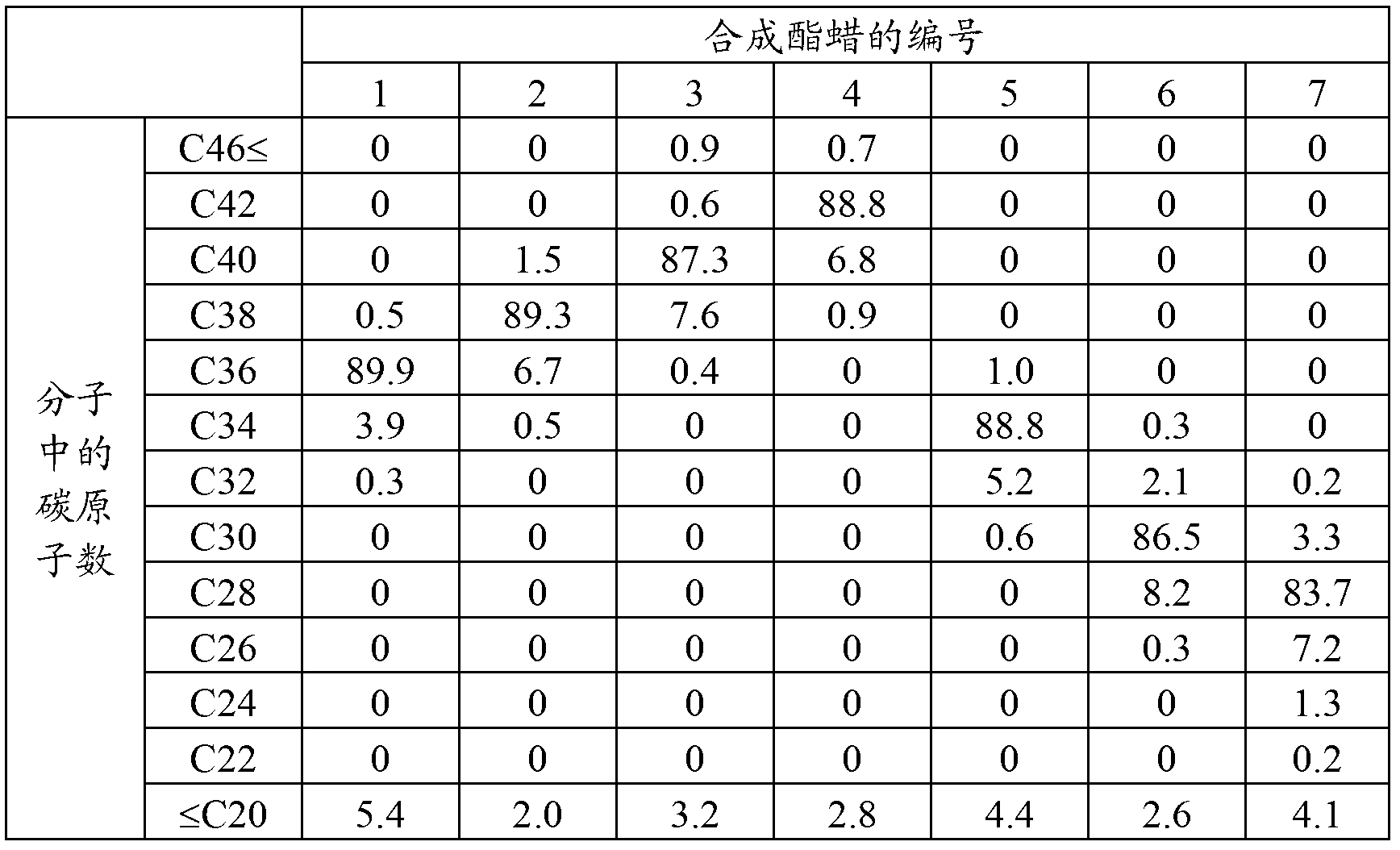

[0429] Add 400 parts of [low-molecular-weight polyester 1], 115 parts of synthetic ester wax (mixture) shown in the following Tables 3-1 and 3-2 (that is, synthetic ester wax ( A mixture of 1) and (2) in a mass ratio of (1) / (2) of 50 / 50) and 1,000 parts of ethyl acetate. Then, the temperature of the resulting mixture was raised to 80°C with stirring, maintained at 80°C for 8 hours, and cooled to 24°C over 1 hour. The obtained dispersion was treated with a bead mill (Ultra Visco Mill, a product of Aymex Co.) under the following conditions: liquid feed rate: 1 kg / hr; disk peripheral speed: 6 m / s; added 0.5 mm ( diameter) zirconia beads: 80% by volume; and the number of passes: 3, whereby the synthetic ester wax (WAX) was dispersed to obtain [wax dispersion 1].

[0430] By measuring the dispersion diameter of [wax dispersion liquid 1] using LA-920, it was found that [wax dispersion liquid 1] had an average particle dia...

Embodiment 5

[0457] [Manufacture of the toner of Example 5]

[0458]

[0459] Add 400 parts of [low-molecular-weight polyester 1], 130 parts of synthetic ester wax (mixture) shown in the following Tables 3-1 and 3-2 (that is, synthetic ester wax ( A mixture of 1) and (4) in a mass ratio of (1) / (4) of 50 / 50) and 1,000 parts of ethyl acetate. Then, the temperature of the resulting mixture was raised to 80°C with stirring, maintained at 80°C for 8 hours, and cooled to 24°C over 1 hour. The obtained dispersion was treated with a bead mill (Ultra Visco Mill, a product of Aymex Co.) under the following conditions: liquid feed rate: 1 kg / hr; disc peripheral speed: 6 m / s; added 0.5 mm (diameter) Amount of zirconia beads: 80% by volume; and Number of passes: 3 to disperse synthetic ester wax (WAX) to obtain [wax dispersion 5].

[0460] By measuring the dispersion diameter of [wax dispersion liquid 5] using LA-920, it was found that [wax dispersion liquid 5] had an average particle diameter (wax...

Embodiment 6

[0484]

[0485] [Crystalline polyester resin 2] (110 g) and ethyl acetate (450 g) were charged into a 2 L metal container. The resulting mixture was dissolved or dispersed under heating at 80° C., and then quenched in an ice-water bath. Subsequently, glass beads (3 mm in diameter) (500 mL) were added to the mixture, followed by stirring for 10 hours with a batch-type sand mill (product of Kanpe Hapio Co., Ltd.), thereby obtaining a particle having a volume average particle diameter of 0.45 μm. [Crystalline polyester dispersion 2].

[0486] [Manufacture of the toner of Example 6]

[0487] The procedure of Example 5 was repeated except that while keeping the total amount of the release agent constant, the combination and mixing ratio of the synthetic ester waxes were changed as described in the following Tables 3-1 and 3-2 to prepare wax dispersions and [Crystalline polyester dispersion liquid 1] was changed to [Crystalline polyester dispersion liquid liquid 2], thereby prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com