Flexible LED device with wire bond free die

A technology of devices and flexible polymers, applied in the direction of electric solid devices, semiconductor devices, circuit bendable/stretchable components, etc., can solve the problem of thick LES devices and packages, increased heat dissipation, material degradation, etc. problem, to achieve the effect of minimizing yield loss, improving light reflection, and improving light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

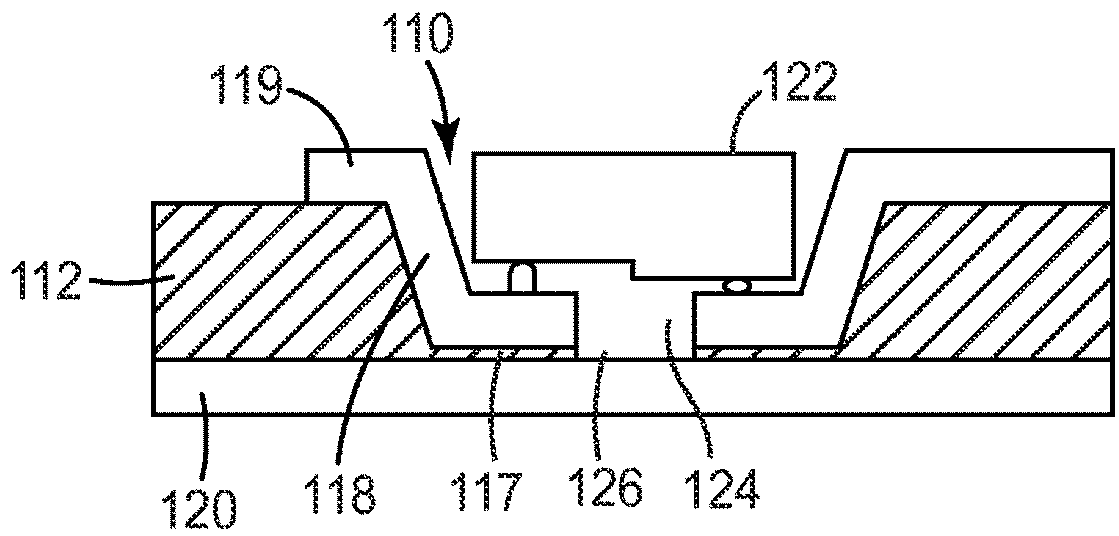

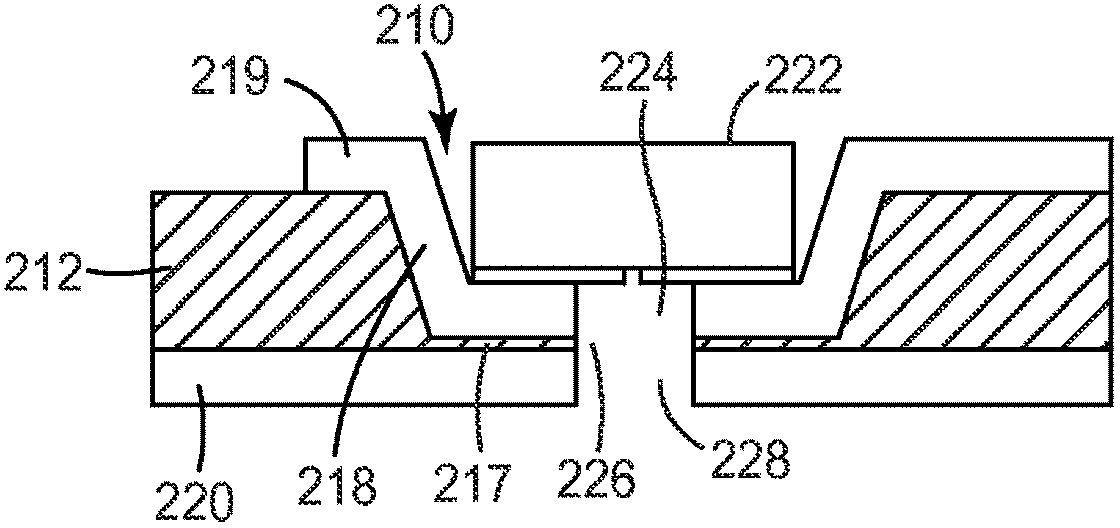

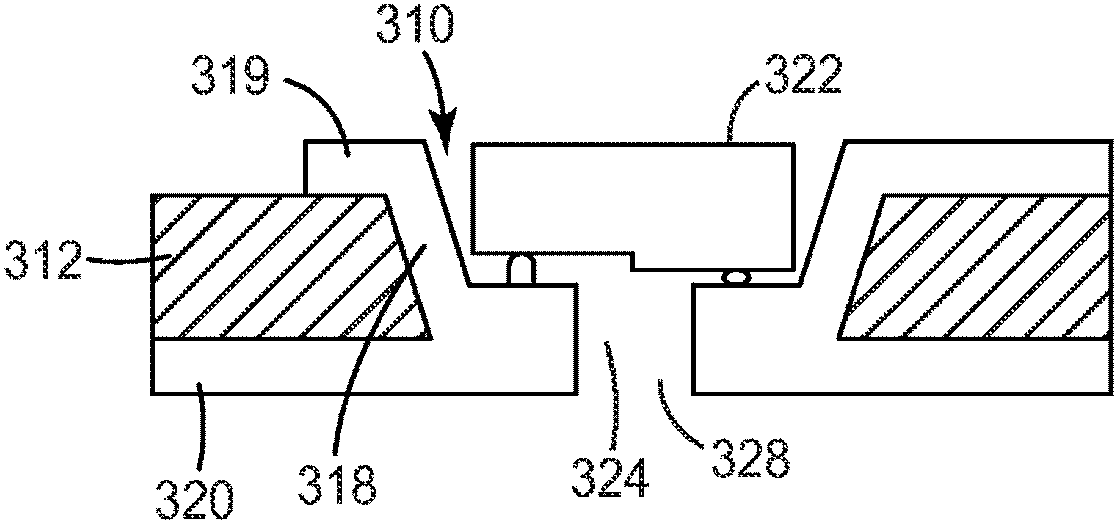

[0082] Embodiment 1 is an article comprising: a flexible polymeric dielectric layer having first and second major surfaces, the first major surface having a conductive layer thereon and at least one cavity therein, the at least A cavity contains conductive material comprising electrically separated first and second portions configured to support and electrically connect a light emitting semiconductor device to the conductive material on the first major surface. layer.

Embodiment 2

[0083] Embodiment 2 is the article of embodiment 1, wherein the conductive material in the cavity is electrically isolated from the second major surface.

Embodiment 3

[0084] Embodiment 3 is the article of embodiment 1, wherein the conductive layer on the first major surface comprises circuitry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com