Distillation apparatus

A technology of distillation apparatus and distillation bottle, which is applied in the field of distillation equipment, can solve the problems of affecting test results, bumping, and no anti-suckback device, etc., and achieve the effect of improving distillation efficiency, speeding up the speed, and preventing suckback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

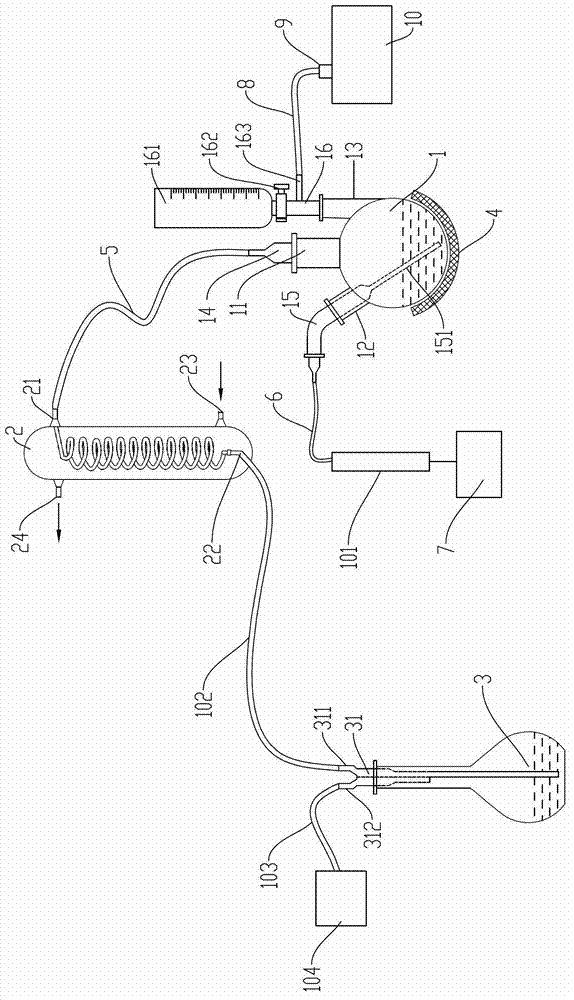

[0017] like figure 1 As shown, the distiller mainly includes a distillation bottle 1, a condensation bottle 2, and a reflux bottle 3; it also includes a heating device 4 corresponding to the distillation bottle 1, a condensation system corresponding to the condensation bottle 2, a control device, and a housing.

[0018] The condensation bottle 2 is provided with a distillation gas inlet 21 , a distillation liquid outlet 22 , a condensate inlet 23 , and a condensate outlet 24 .

[0019] The distillation bottle 1 is provided with three bottlenecks, which are respectively denoted as a first bottleneck 11 , a second bottleneck 12 and a third bottleneck 13 .

[0020] in:

[0021] The first bottle mouth 11 is sealed with a first bottle stopper 14, one end of the first bottle stopper 14 communicates with the inner cavity of the distillation bottle 1, and the other end of the first bottle stopper 14 is connected to the distillation gas inlet 21 of the condensation bottle through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com