Method for actively regulating mixture ratio of spacecraft propellant

An adjustment method and propellant technology, which is applied in the fields of aerospace vehicle propulsion system devices, jet propulsion devices, machines/engines, etc., can solve the problems of low effective use of propellant and large residual propellant, and improve the effective utilization efficiency, improved payload quality, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

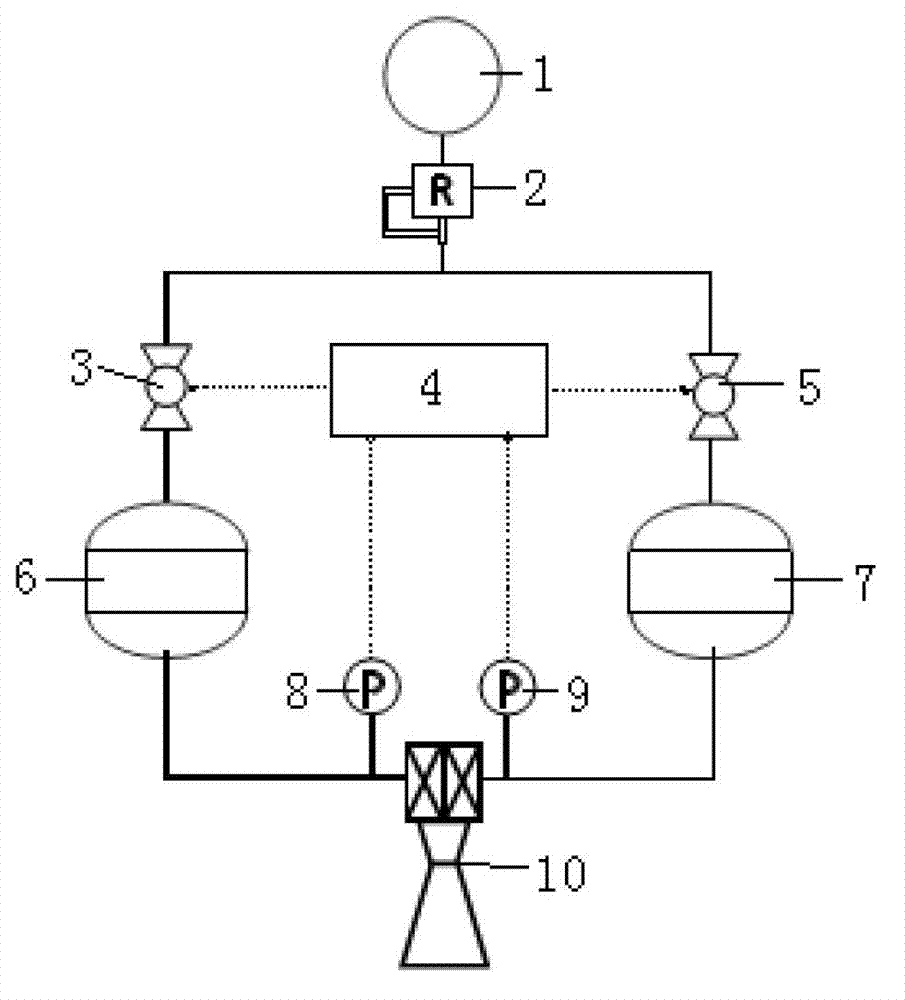

[0015] like figure 1 As shown, the spacecraft propulsion system adopted by the present invention is composed of an internal gas source 1, a pressure reducing valve 2, an oxidant gas supply self-locking valve Lo3, a controller 4, a fuel gas supply self-locking valve Lf5, an oxidant storage tank 6, and a fuel storage tank 7. It is composed of oxidant path pressure Po8, fuel path pressure Pf9, and main engine 10.

[0016] Test run the main engine with large propellant consumption in the spacecraft propulsion system before installing it into the system, measure the working parameters, and then adjust the hardware of the spacecraft propulsion system so that the oxidant and fuel are at the standard inlet pressure (generally the inlet pressure of oxidant and fuel are equal, but this is not a necessary condition) to achieve the standard mixing ratio, and then assembled into the propulsion system (generally, the error of the mixing ratio of the main engine itself can be controlled belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com