Antifreezing concrete

A technology of antifreeze concrete and phase change energy storage materials, applied in the field of antifreeze concrete, can solve problems such as high quality management requirements, deterioration of concrete structures, economic losses and rising maintenance costs, so as to avoid affecting traffic safety and alleviate damage or deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

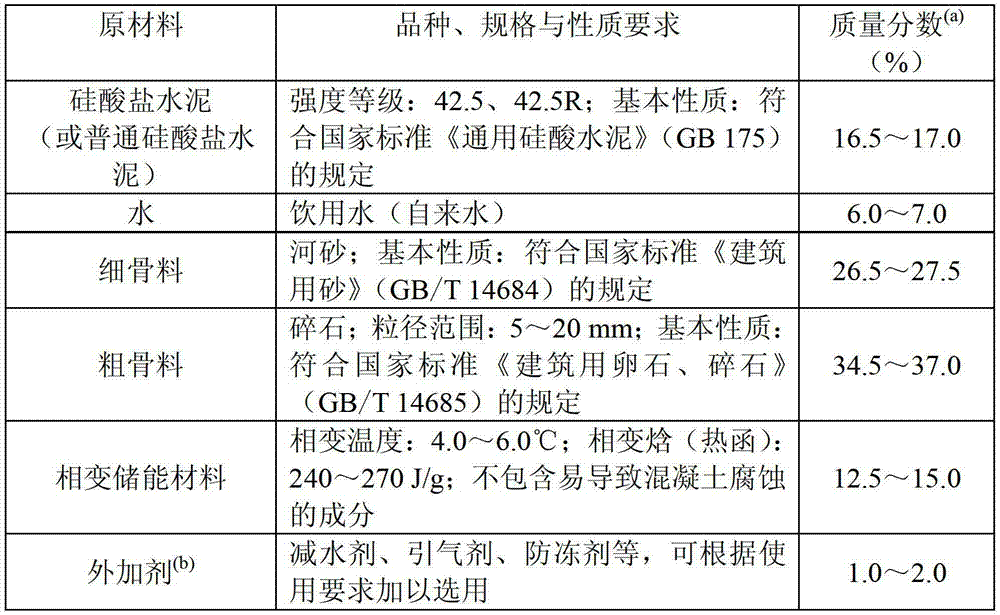

Method used

Image

Examples

Embodiment 1

[0010] An antifreeze concrete made of the following components in unit dosage (kg / m3): ordinary Portland cement 400, water 182, fine aggregate 635, coarse aggregate 876, n-tetradecane 312, water reducing agent 1.7 .

[0011] According to the conventional anti-freeze concrete construction operation method, the anti-freeze concrete containing the phase change energy storage material in the present invention is constructed on site. When the concrete is cured to the age of 56 days, use temperature-controlled freeze-thaw equipment to perform freeze-thaw cycle testing on the reserved standard specimens maintained under the same conditions according to the local winter typical temperature history, and compare it with those that do not contain phase change energy storage materials. Concrete (except without n-tetradecane, other raw materials and amounts are the same as those listed above; the curing conditions are also the same as antifreeze concrete containing phase change energy storage...

Embodiment 2

[0014] An antifreeze concrete made of the following components in unit dosage (kg / m3): ordinary Portland cement 425, water 173, fine aggregate 642, coarse aggregate 896, paraffin wax 331, and water reducing agent 1.8.

Embodiment 3

[0016] An antifreeze concrete made of the following components in unit dosage (kg / m3): Portland cement 433, water 167, fine aggregate 688, coarse aggregate 902, polyethylene glycol 296, and water reducing agent 1.7.

[0017]

[0018] Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com