Structure and method for repairing cracks of oblique prestressed cement concrete pavement

A technology for cement concrete and pavement cracks, applied in the directions of roads, roads, pavement details, etc., can solve the problems of pavement base damage, easy peeling, pavement structure damage, etc., to achieve the effect of strong reliability and simple and easy repair methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

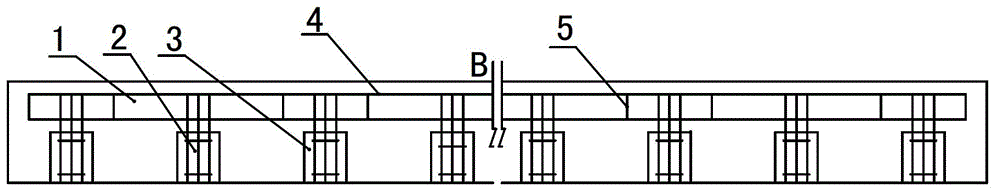

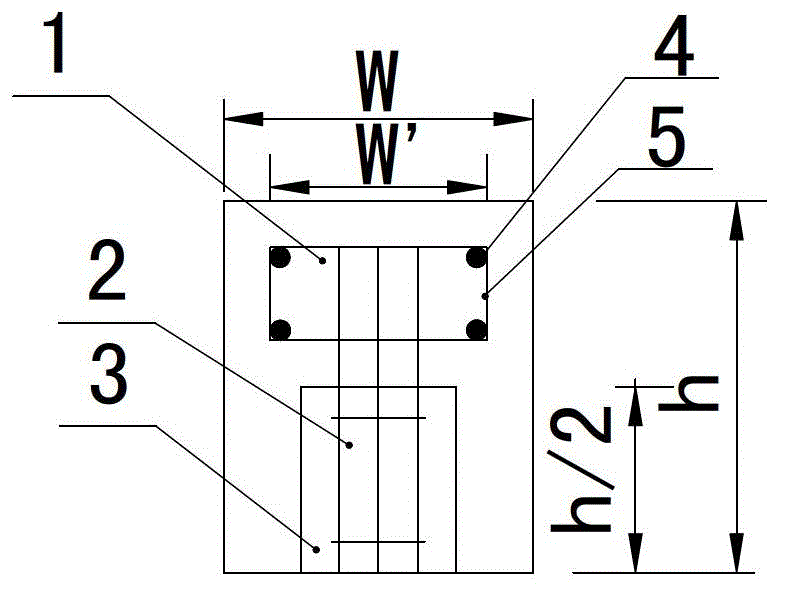

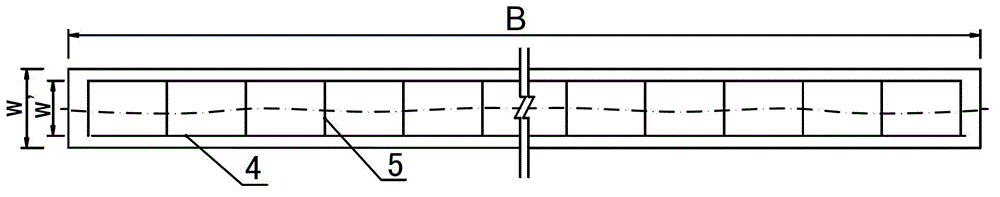

[0026] refer to figure 1 , figure 2 , which is a vertical elevation view and a cross-sectional elevation view of an oblique prestressed cement concrete pavement crack repair structure and repair method of the present invention. Wherein, it is assumed that the width of the oblique prestressed cement concrete pavement is B, the height of the cement concrete slab is h, and there are slots cut with a cutting machine along the cracks in the road surface. The width of the slots is W, and W is the minimum of the crack. The width of the repair (when the crack is at an angle of θ to the transverse line of the road surface, W=B*tgθ), the bottom surface of the slot is located above the prestressed steel bar, which is h / 2. Drill holes 3 with a diameter of 10 cm at the bottom of the prestressed steel bars with an electric drill, the holes 3 are arranged at intervals of 20 cm, the depth of the holes is h / 2, and the holes 3 communicate with the sliding layer. A horizontal reinforcement ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com