Underground coal mine large channel end socket suspension hydraulic support

A technology of hydraulic support and large passage, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of high labor intensity of workers, low support work efficiency, inability to install loader, etc., to improve work efficiency and Safety performance, achieve balanced production, reduce unsafe accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

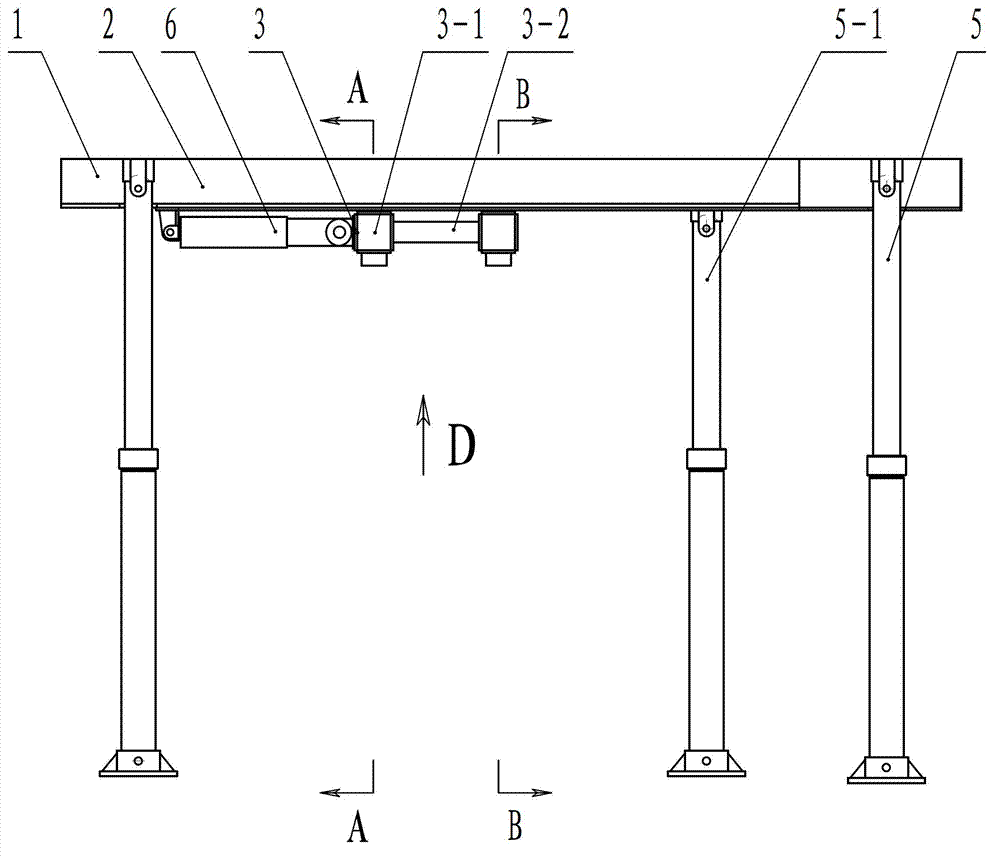

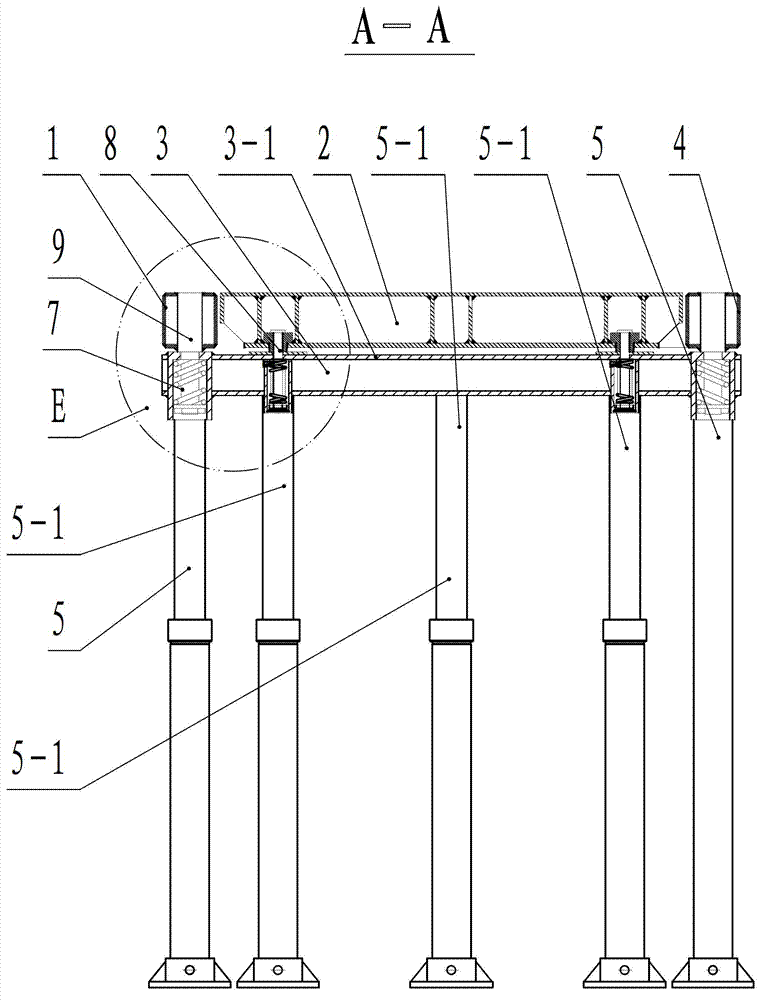

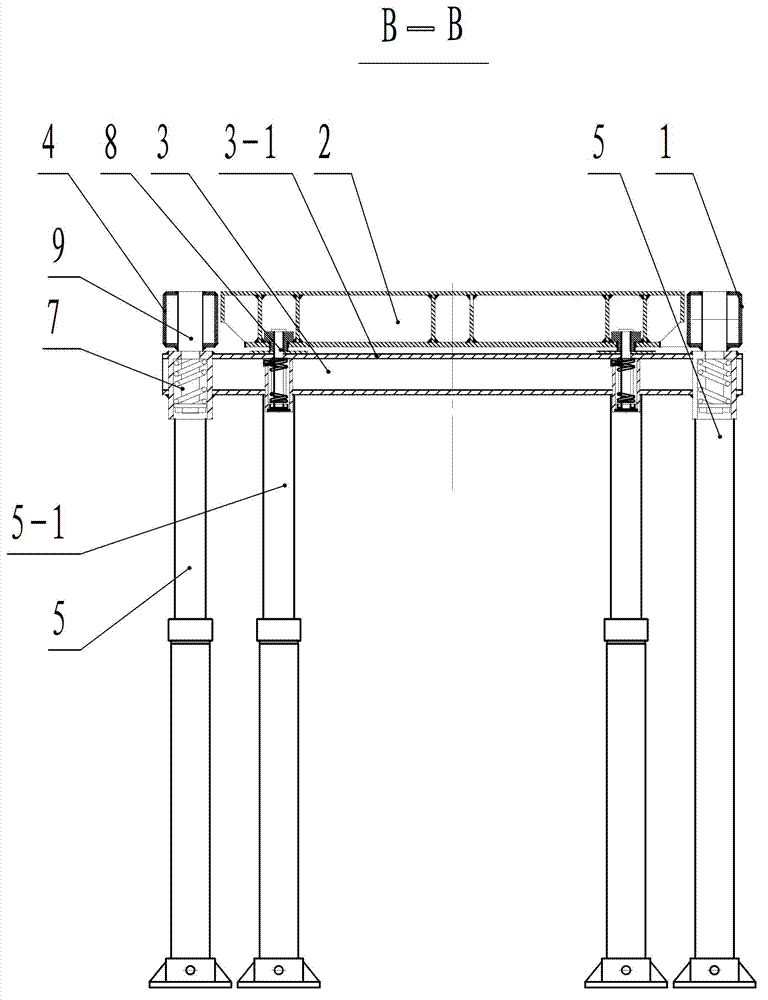

[0024] Such as Figure 1 to Figure 5 Shown: a suspension hydraulic support at the end of a large underground passage in a coal mine, which includes a left top beam 4, a right top beam 1, a middle top beam 2 and a hydraulic prop 5. The left and right top beams 4 and 1 are rectangular tubes, and the rectangular tubes are supported by hydraulic props I5; the middle top beams 2 are rectangular square tubes, and the middle top beams 2 are supported by hydraulic props II5-1. It is characterized in that: the ends of the left and right top beams 4 and 1 are supported by only one hydraulic prop I5, the four corners of the middle top beam 2 are each supported by a hydraulic prop II5-1, and the middle top beam 2 A hydraulic prop Ⅰ5-1 is added to the rear end of the support;

[0025] The lower part of the middle top beam 2 is provided with a bracket 3, and the bracket 3 is composed of two parallel bracket beams 3-1 and two bracket connecting beams 3-2 to form a well-shaped frame plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com