Coastal wave cyclone power generation method and installation

A power generation device and coastal wave technology, which is applied in the directions of ocean energy power generation, engine components, machines/engines, etc., can solve the problems of difficulty in capturing wave energy and uneconomical economy, and achieve good continuity and stability. The effect of improving the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

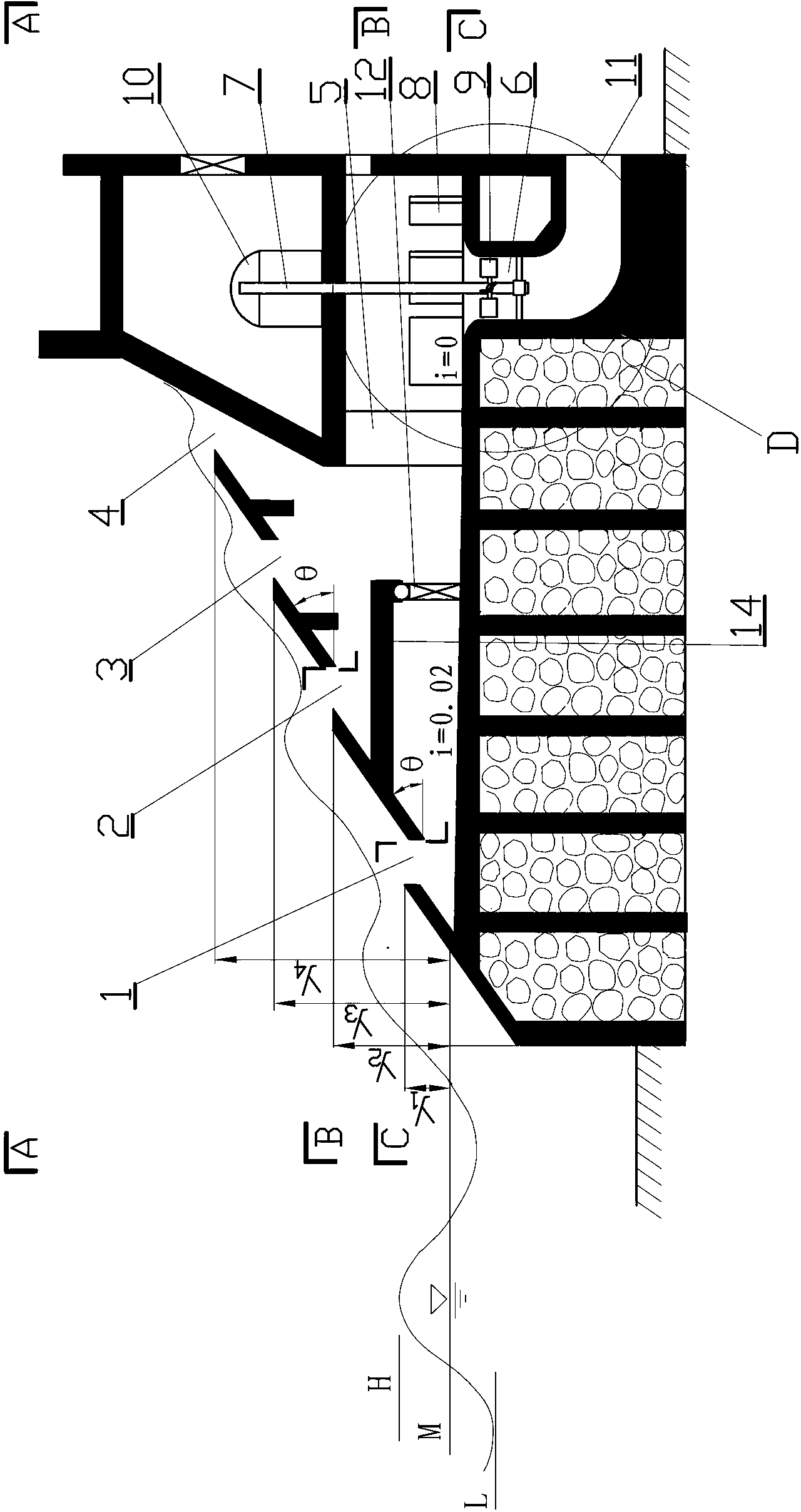

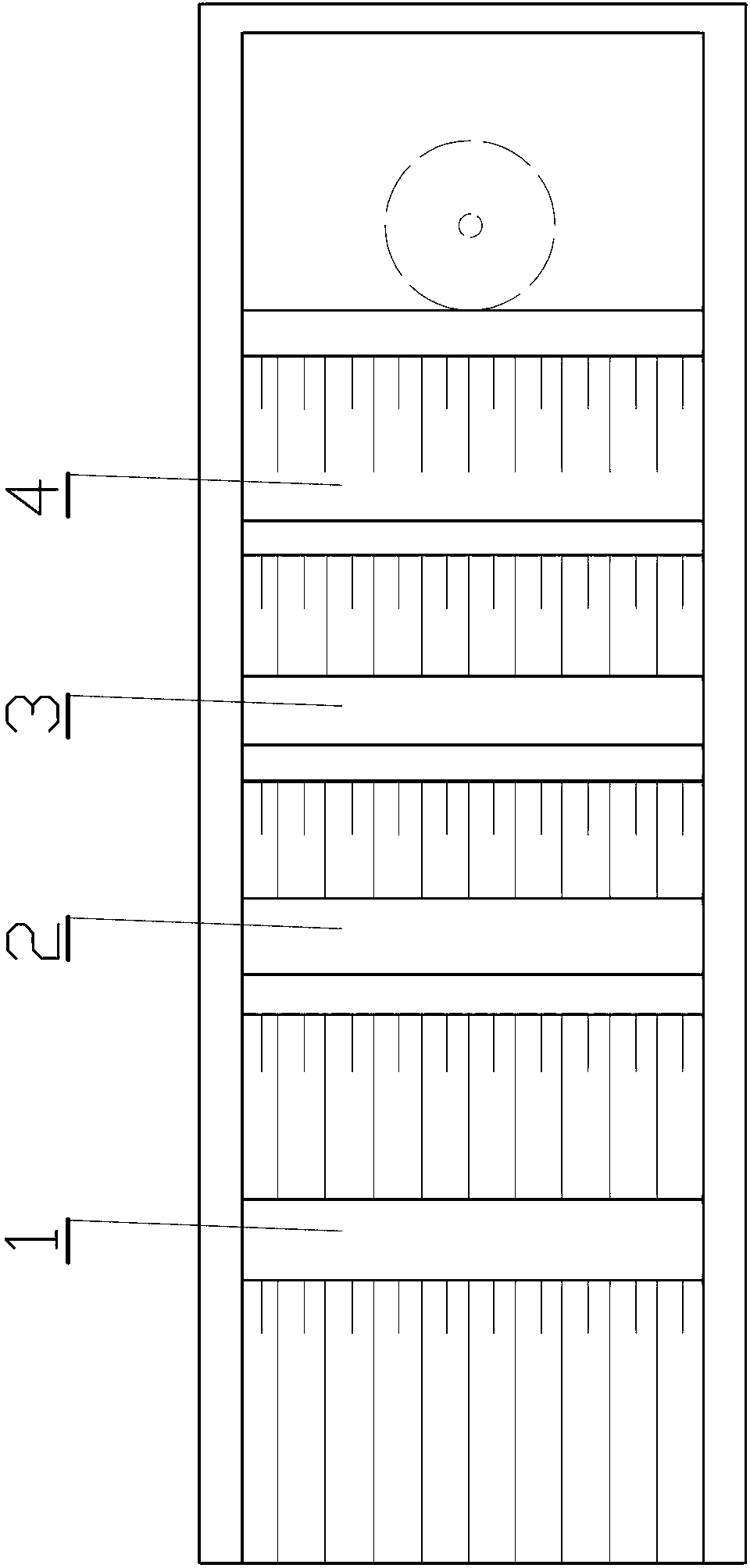

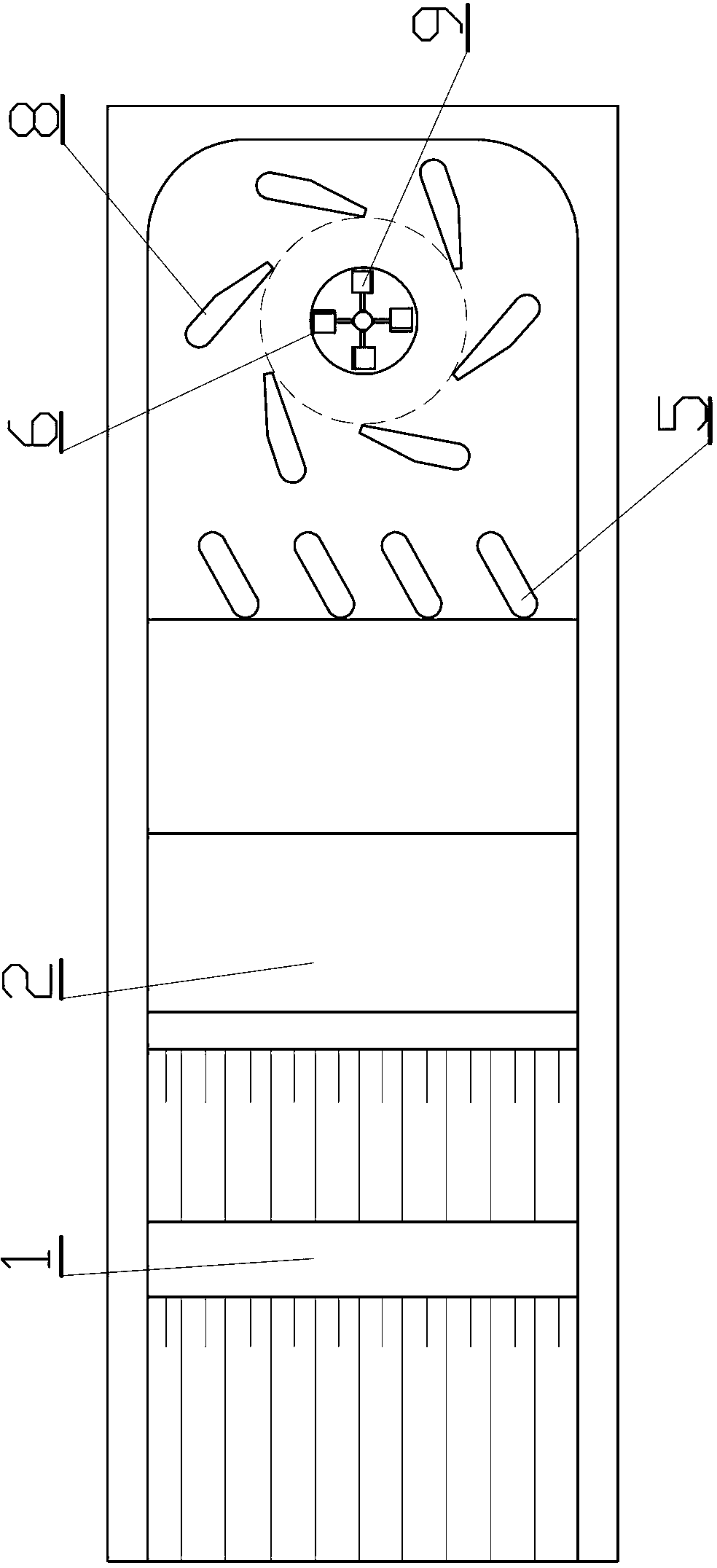

[0027] This embodiment is a coastal wave energy swirling power generation device, such as figure 1 , 2 , 3, 4, and 5. This embodiment includes: a slope facing the sea arranged on the coastline, and on the slope facing the sea, multi-layer water intakes ( Figure 1-4 Only 4 water intakes are drawn in the figure, which may actually be more than two water intakes), the water intakes are connected to the pools that store seawater, and the bottom plate of the pools is slightly lower than the average tide level. On the bottom plate of the pools A contraction diversion wall is set, and a one-way flap door is installed at the shrinkage port of the shrinkage diversion wall, and a plurality of diversion piers are arranged horizontally downstream of the one-way flap door, and a bell mouth vertical pipe is arranged downstream of the diversion piers , the bell-mouth standpipe is installed with a water turbine coaxially connected with the generator, and the bell-mouth standpipe is connect...

Embodiment 2

[0035] This embodiment is an improvement of the first embodiment, and it is a refinement of the first embodiment on the slope of the seaward surface. The oblique wave on the seaward surface described in this embodiment gradually widens from top to bottom, and energy-gathering side walls 15 (suitable for construction on distant sea islands) are arranged on both sides of the oblique wave on the seaward surface, as shown in Image 6 shown.

[0036] The energy-gathering side walls are two gradually retracted walls built on both sides of the slope facing the sea, which can make the width of the waves gradually narrow when they rush from the sea to the shore, and at the same time gradually increase the height of the waves, that is, the kinetic energy of the waves is Potential energy is formed between the two gradually gathering energy walls, which can rush into a higher water intake. Image 6 A slope facing the sea with four water intakes is drawn in , and if built on a coastline b...

Embodiment 3

[0038] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment regarding the slope of the seaward surface. The inclination angle of the ramp wave on the seaward surface described in this embodiment is 30-35 degrees.

[0039] The slope between the water intakes of each layer can be changed, for example, the slope gradually increases from bottom to top, so that the width of the water intake can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com