Heating floor

A floor and floor board technology, applied in heating methods, electric heating systems, household heating, etc., can solve the problems of large wire usage, high cost, complicated wiring, etc., save time and effort in the installation process, avoid leakage phenomenon, and reduce costs cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

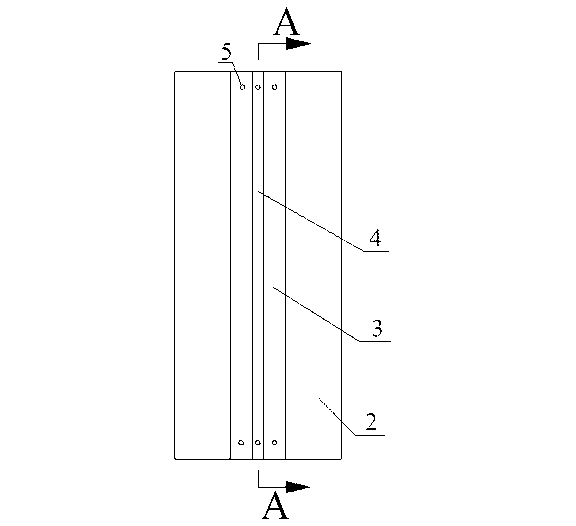

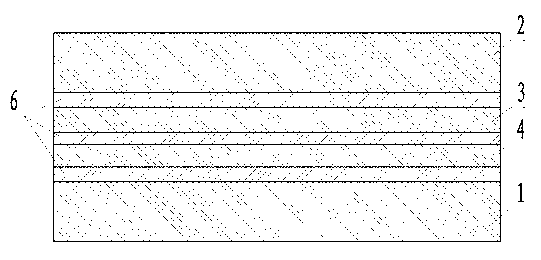

[0012] Embodiments are described in detail with reference to the accompanying drawings. A heating floor, including a plurality of assembled floorboards, each floorboard mainly includes a substrate 1, a surface layer 2 and a conductive heating layer arranged between the substrate and the surface layer, wherein the substrate 1 is a high-temperature reinforced composite board, The surface layer 2 is a wooden floor, and the conductive heating layer is a carbon crystal plate. The carbon crystal plate includes a heating carbon crystal 3 and an epoxy resin plate 6 coated on both sides of the heating carbon crystal. The conductive heating layer and the substrate 1 Copper foil 4 is arranged in between, and the two sides of the substrate 1 are respectively perforated. The conductive heating layer opposite to the substrate 1 and the two sides of the copper foil 4 are respectively provided with contacts 5, and the contacts 5 are respectively connected with wires passing through the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com