Heat Exchanger

A heat exchanger and heat exchange medium technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as difficult cleaning, easy to be blocked, and many dead ends in the shell side, so as to increase the space in the tube and solve the problem of easy blockage , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

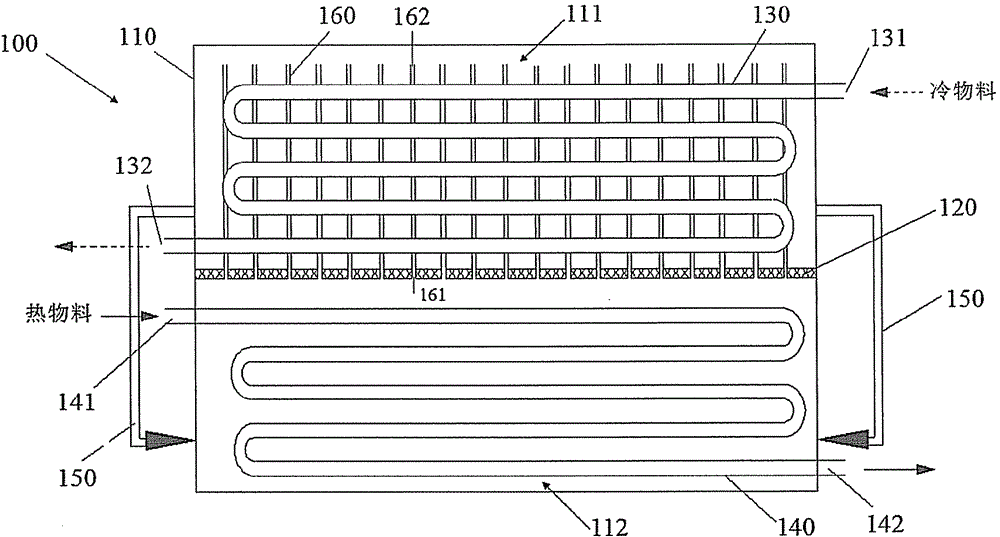

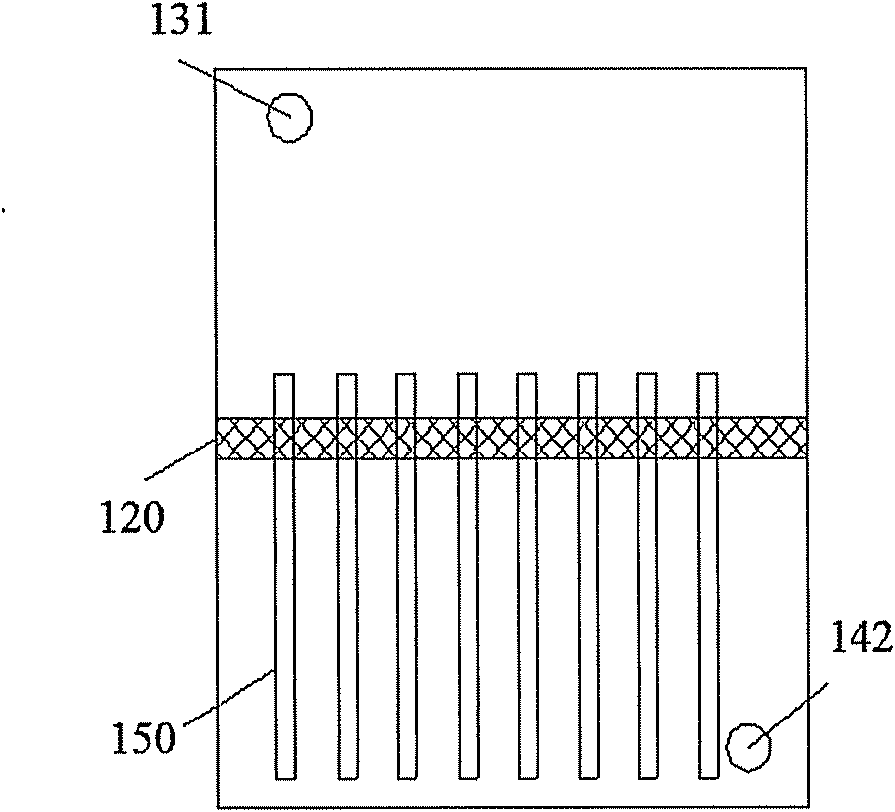

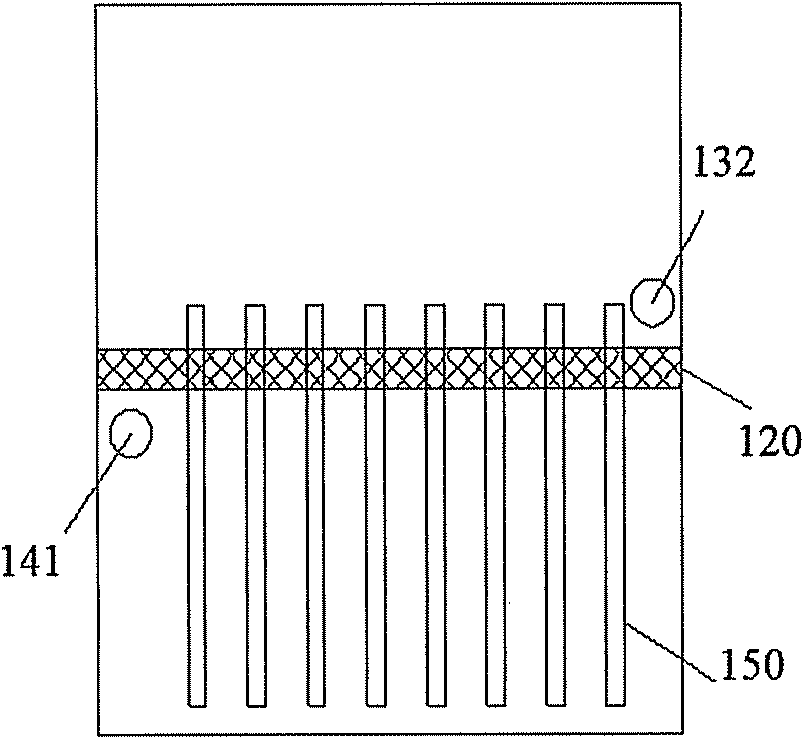

[0036] figure 1 The structure of a heat exchanger 100 according to one embodiment of the present invention is shown. The heat exchanger according to the present invention is suitable for high temperature and high pressure occasions, for example, it can be used for heat exchange or heat exchange of impurity-containing fluids. Such as figure 1As shown, the heat exchanger 100 includes a shell 110, the inner space of the shell 110 is divided into an upper heat medium distribution chamber 111 and a lower cold medium distribution chamber 112, and the distribution chambers 111 and 112 are respectively filled with the same heat exchange medium, such as mercury , heat transfer oil, high temperature steam, naphthalene, biphenyl, potassium, cesium or sodium, etc. According to an example, the upper heat medium distribution chamber 111 and the lower cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com