Patents

Literature

32results about How to "Full waste heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

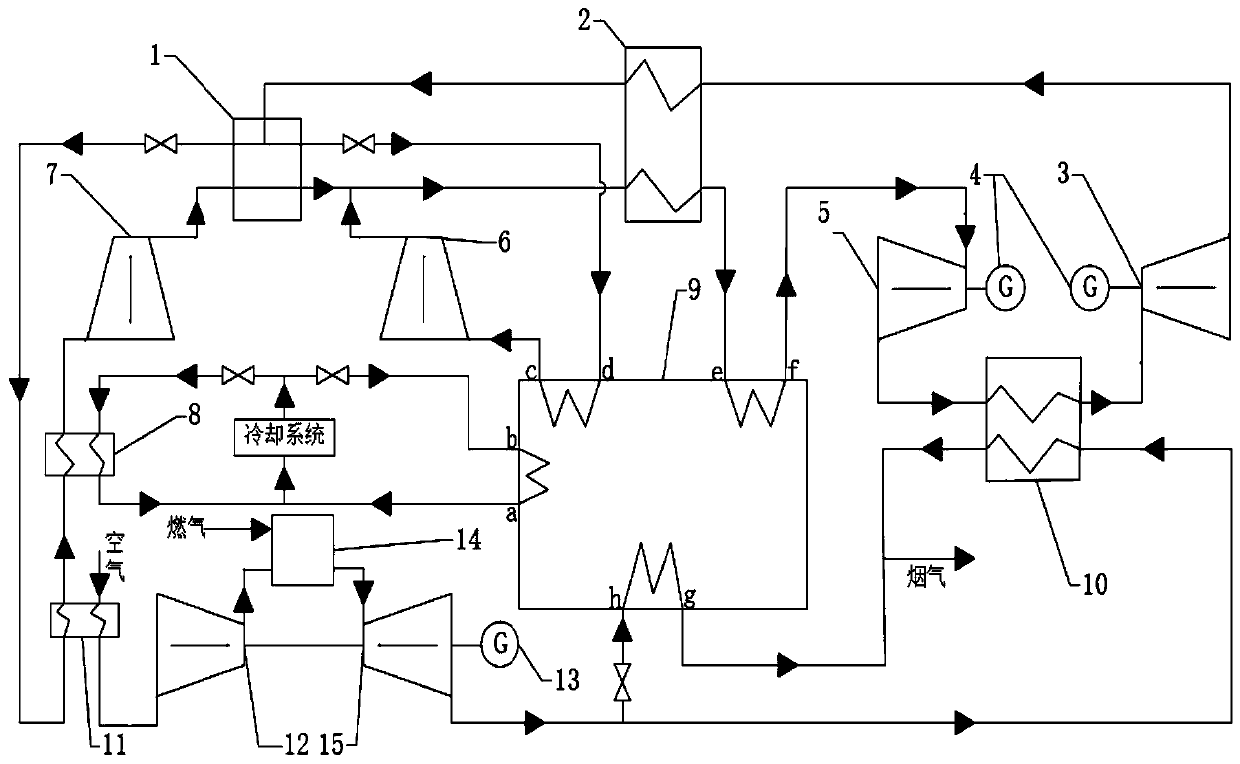

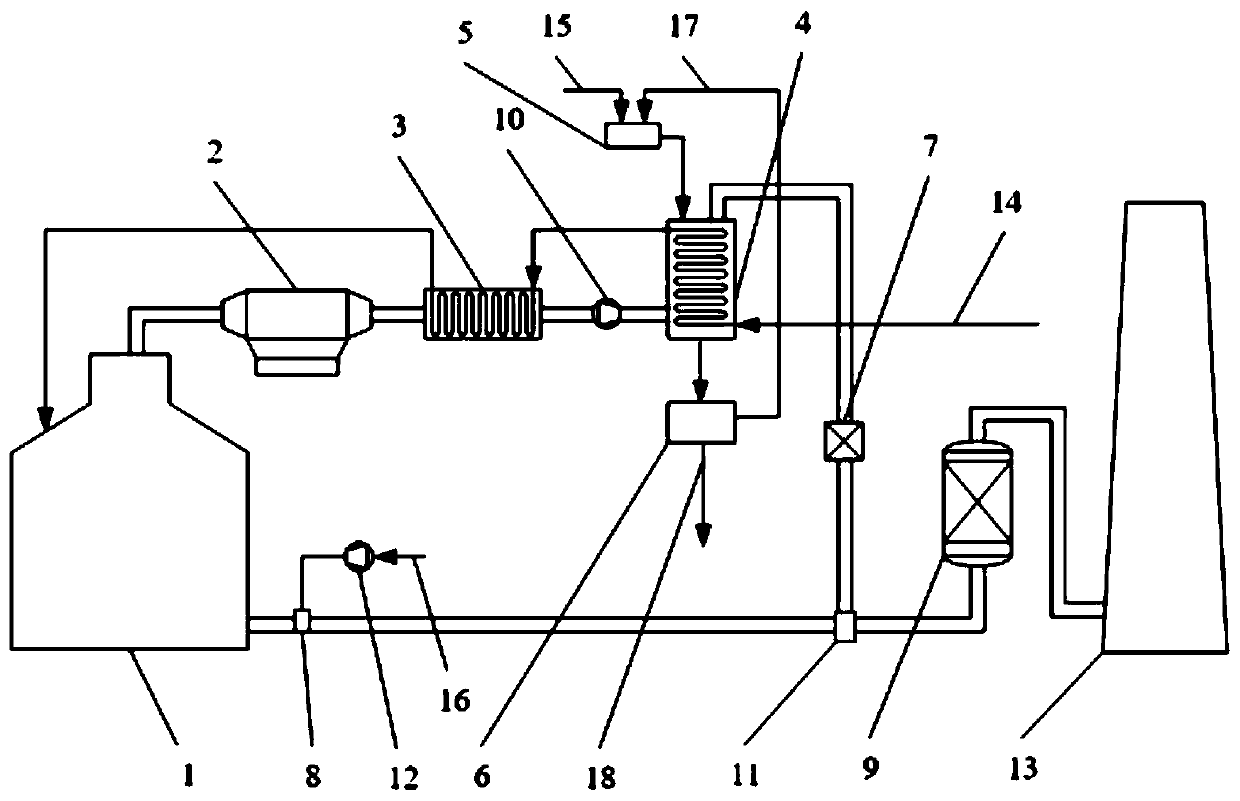

Supercritical carbon dioxide power generation system based on absorption heat pump waste heat recovery

ActiveCN111022138ALower exhaust gas temperatureHigh thermal efficiencyHeat recovery systemsGas turbine plantsAbsorption heat pumpSupercritical carbon dioxide

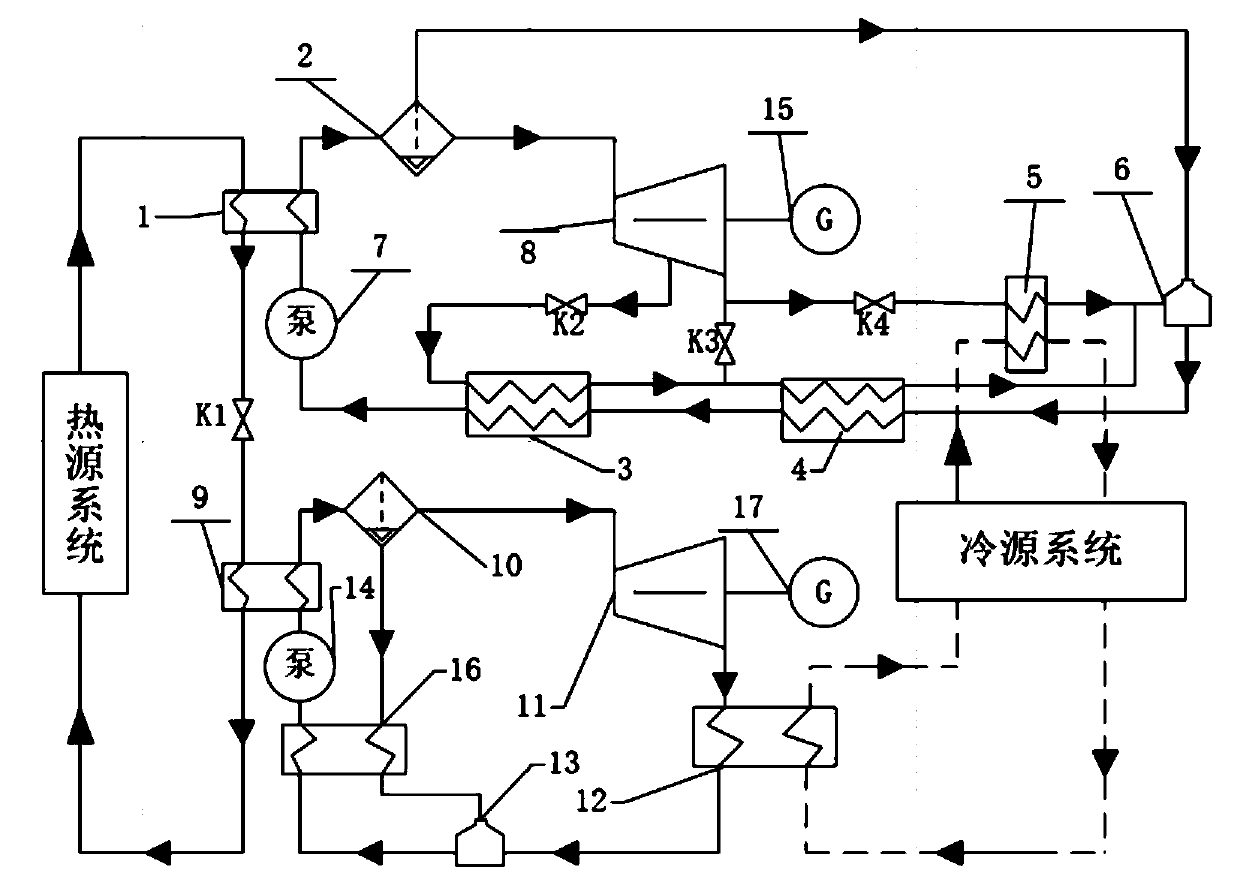

The invention discloses a supercritical carbon dioxide power generation system based on absorption heat pump waste heat recovery. The supercritical carbon dioxide power generation system comprises a supercritical carbon dioxide Brayton cycle system, an absorption heat pump cycle system, a traditional gas-fired Brayton cycle system and a cooling system. The cooling system is responsible for providing cold required for condensation of the supercritical carbon dioxide Brayton cycle system and the absorption heat pump cycle system, and the traditional gas-fired Brayton cycle system provides high-temperature heat sources for the supercritical carbon dioxide Brayton cycle system and the absorption heat pump cycle system respectively while producing most of electric energy of the entire system. The overall thermal efficiency of the system can be improved while the exhaust gas temperature of a gas turbine is reduced. The supercritical carbon dioxide Brayton cycle system heats dead steam of a high-pressure turbine by utilizing flue gas waste heat in a flue gas regenerator, the dead steam continues to drive a low-pressure turbine to work after being heated, thus, the cycle thermal efficiencyis further improved, and the power generation efficiency is improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

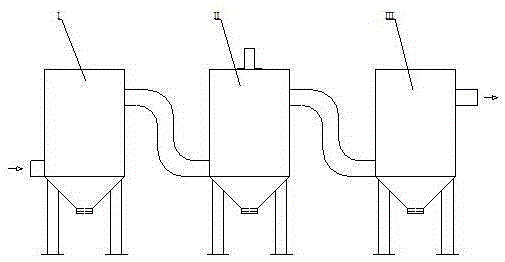

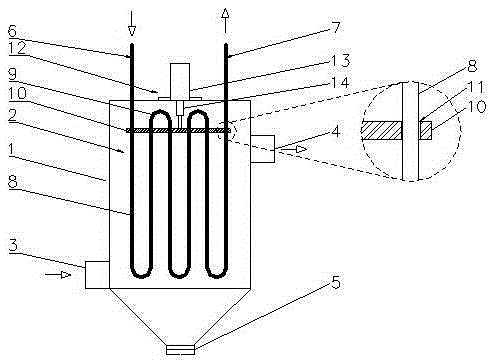

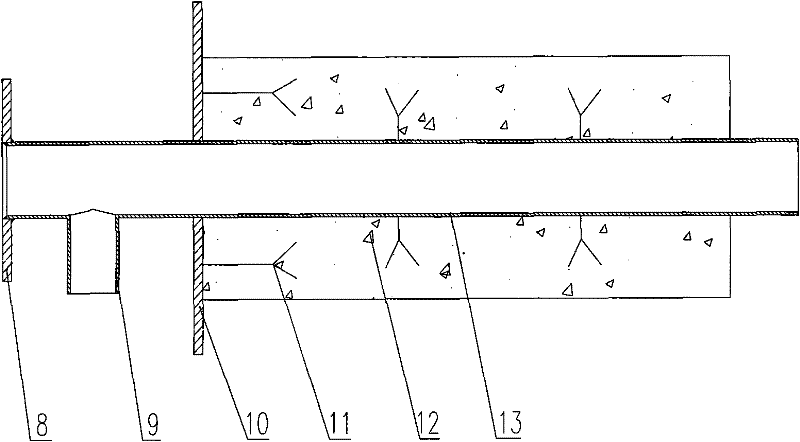

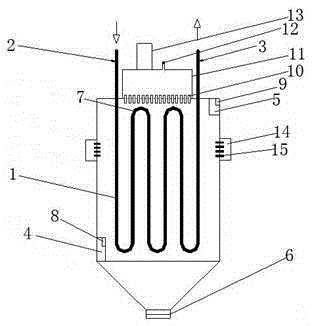

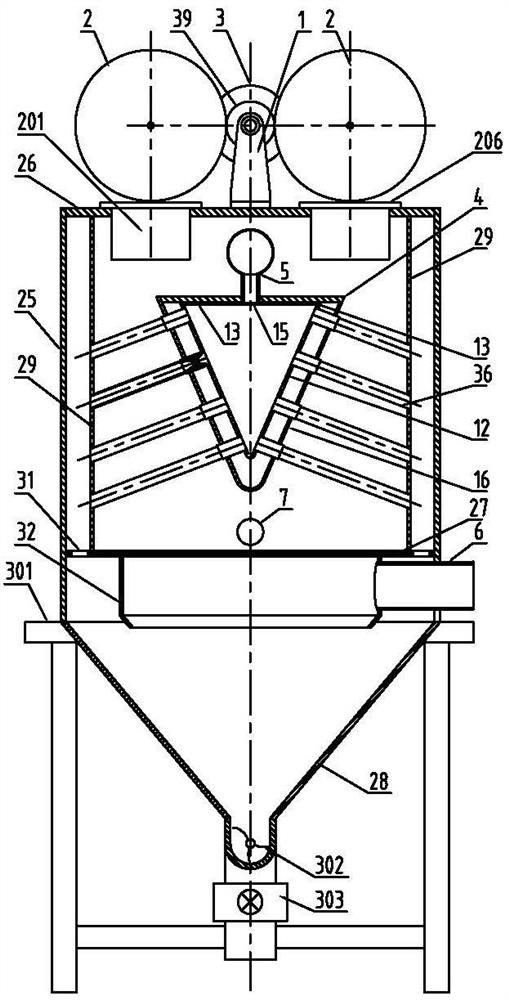

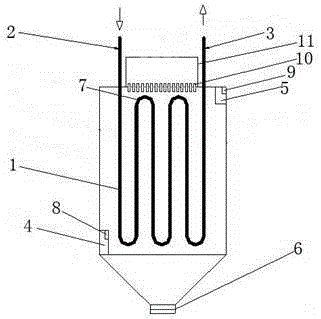

High-temperature flue gas dust removal and waste heat utilization system of metallurgical furnace

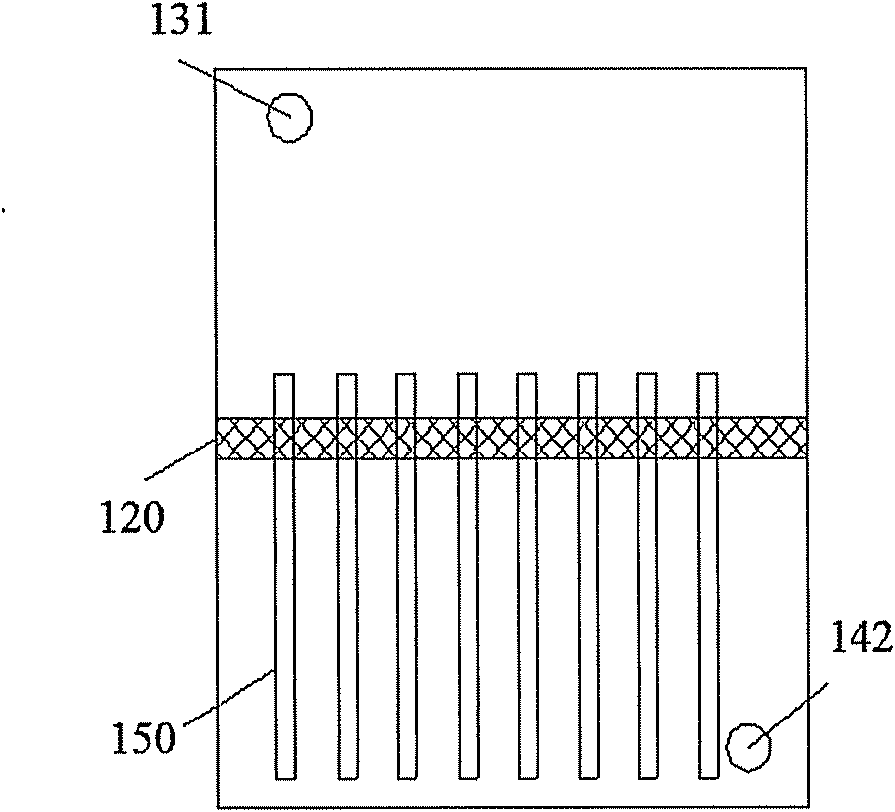

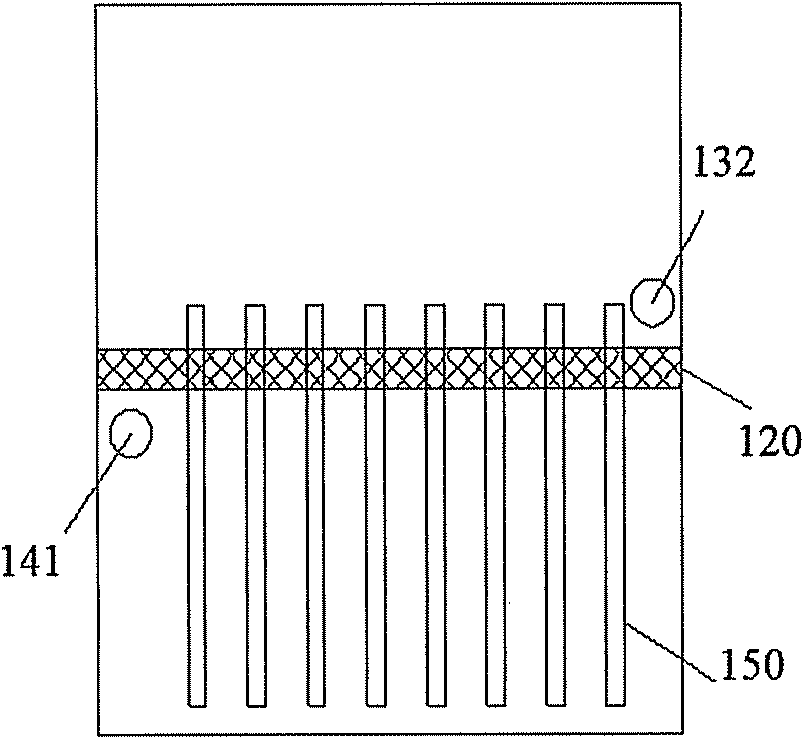

InactiveCN105318736ALower discharge temperatureHigh economic valueIncreasing energy efficiencyWaste heat treatmentHydraulic cylinderVertical tube

The invention relates to a high-temperature flue gas dust removal and waste heat utilization system of a metallurgical furnace. The system comprises a first-stage electric precipitator, a waste heat utilization device and a second-stage electric precipitator which are sequentially communicated, wherein the waste heat utilization device comprises a heat exchange tank and a heat exchange tube row; the heat exchange tube row is sleeved with a dedusting board; multiple through holes are formed in the dedusting board; vertical tubes of the heat exchange tube row penetrate through the through holes and are in sliding connection with the through holes of the dedusting board; a hydraulic cylinder is fixedly arranged on the top of the heat exchange tank; a cylinder barrel of the hydraulic cylinder is fixed to the top of the heat exchange tank; a piston rod of the hydraulic cylinder penetrates through the top of the heat exchange tank and is fixedly connected with the dedusting board inside the heat exchange tank. By means of the high-temperature flue gas dust removal and waste heat utilization system of the metallurgical furnace, the hydraulic cylinder drives the dedusting board to vertically move, smoke of the tube walls of the vertical tubes of the heat exchange tube tow is scraped, the higher heat exchange efficiency can be kept continuously, waste heat is sufficiently recycled, and the economic value of the waste heat system is improved.

Owner:马忠华

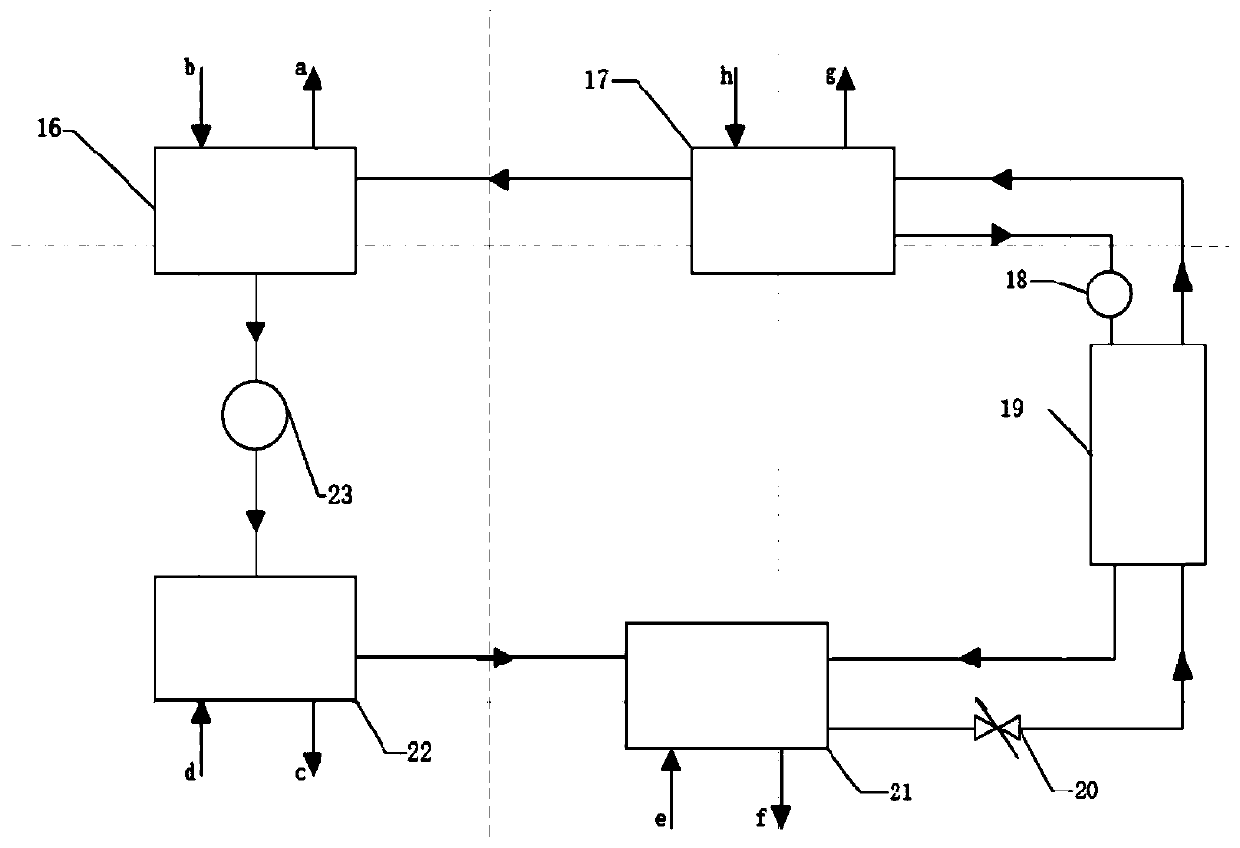

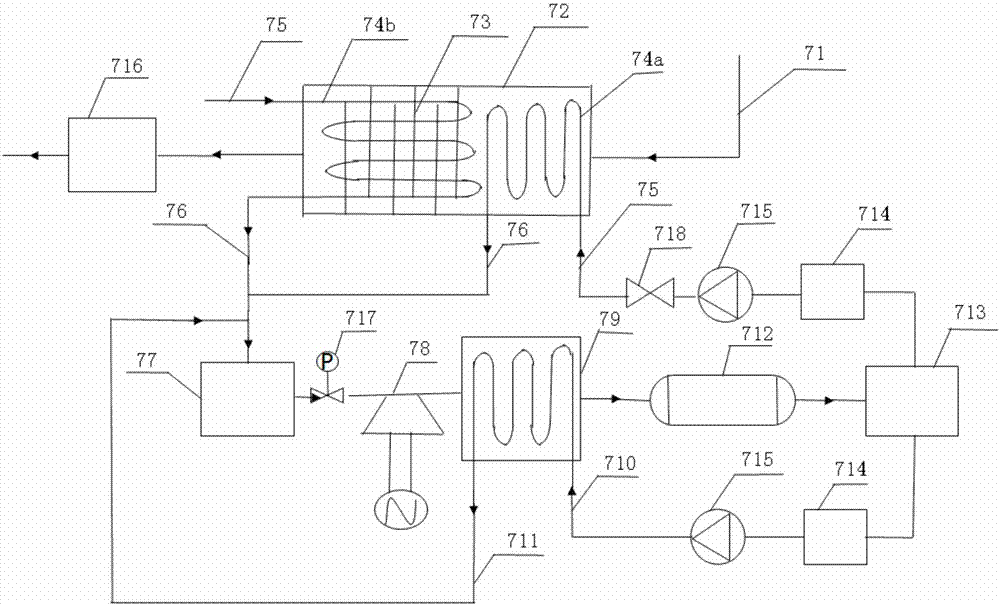

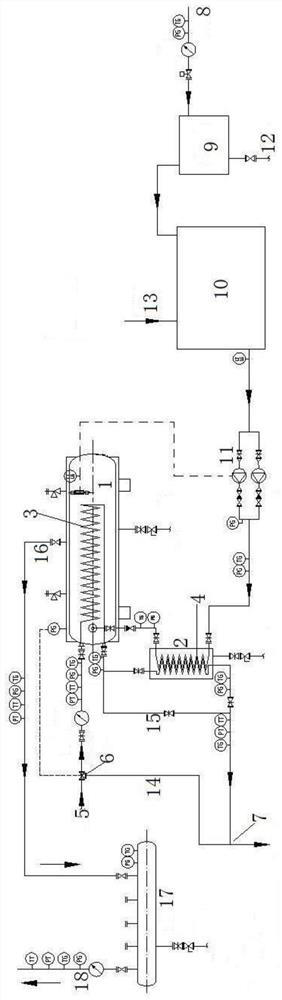

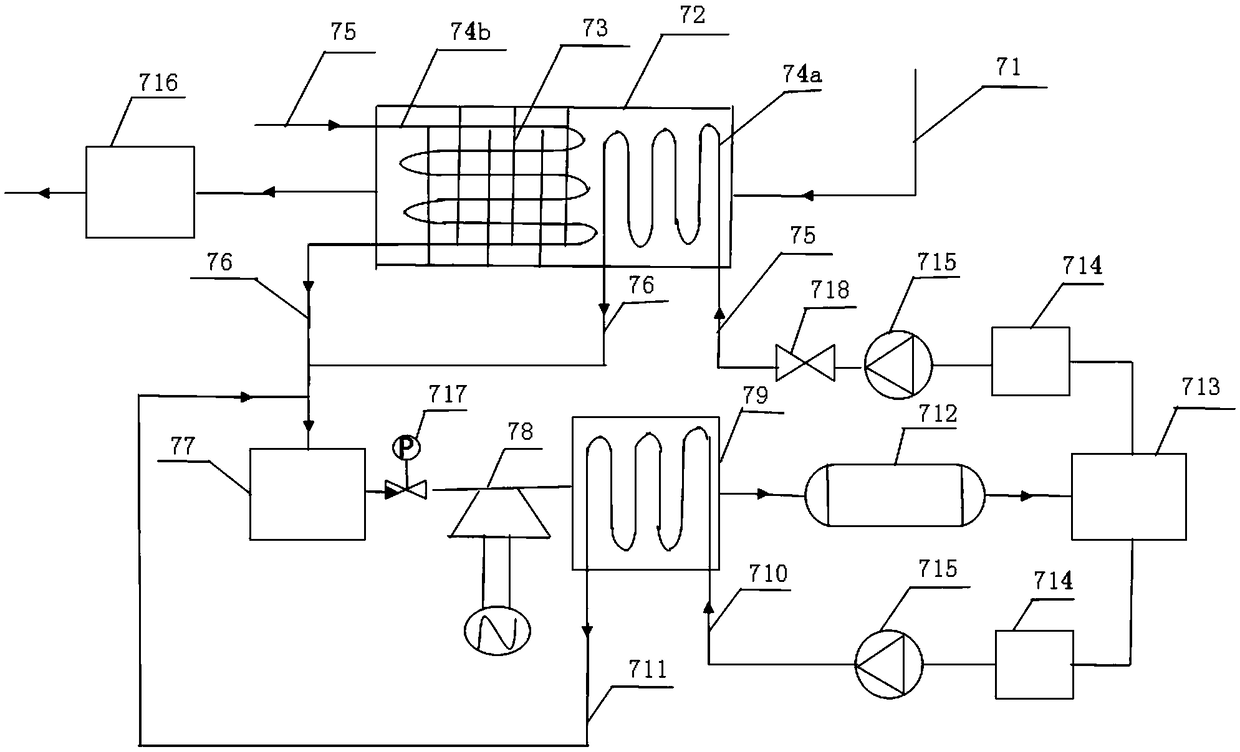

High-low pressure double-working-medium ORC power generation system with regenerative cycle

ActiveCN111075521AHigh thermal efficiencyReduce heat loadSteam useEnergy industryCooling capacityLoad following power plant

The invention discloses a high-low-pressure double-working-medium ORC power generation system with regenerative cycle. The system comprises a high-pressure cycle power generation system, a low-pressure cycle power generation system, a cold source system and a heat source system. The high-pressure cycle power generation system and the low-pressure cycle power generation system adopt different working media to carry out gradient recovery on heat of different grades of the heat source system; on the basis that a steam extraction heat regenerator and an exhaust steam heat regenerator are arranged,the high-pressure cycle power generation system is further provided with a bypass loop so as to ensure safe operation of the unit; and the cold source system provides cooling capacity required by condensation for condensers of the high-pressure cycle power generation system and the low-pressure cycle power generation system. According to the system, on the basis of existing ORC cycle, a traditional waste heat recovery method is improved, waste heat is recovered in a stepped mode through the high-low pressure double-working-medium ORC power generation system with the regenerative cycle, the heat load of an evaporator is reduced, and the heat efficiency of the ORC power generation system is effectively improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

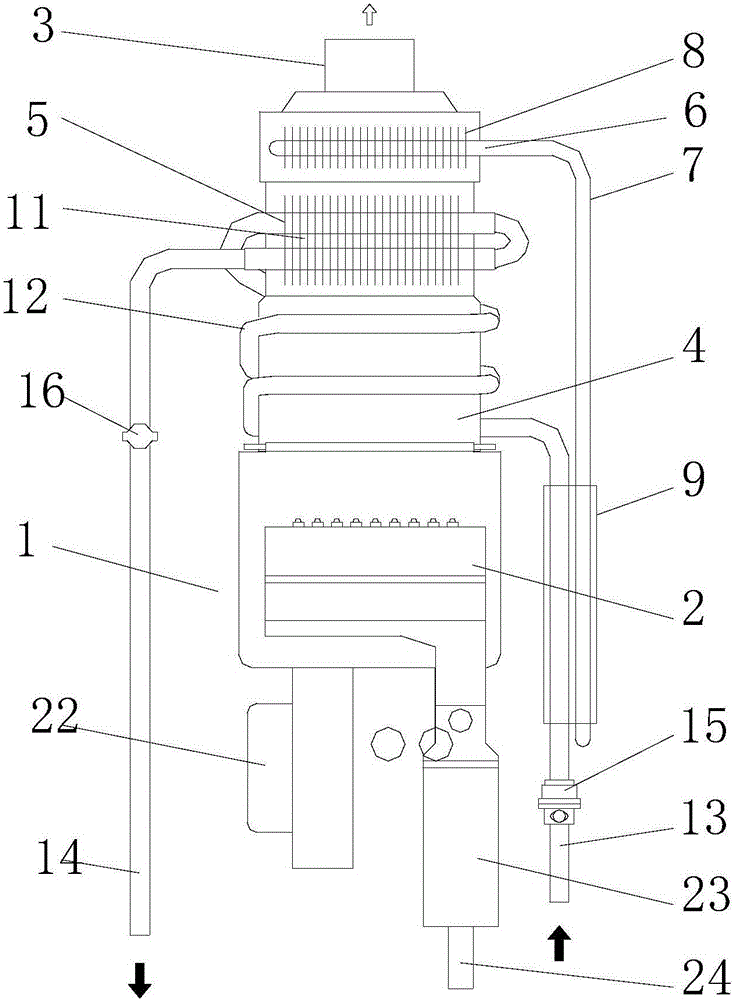

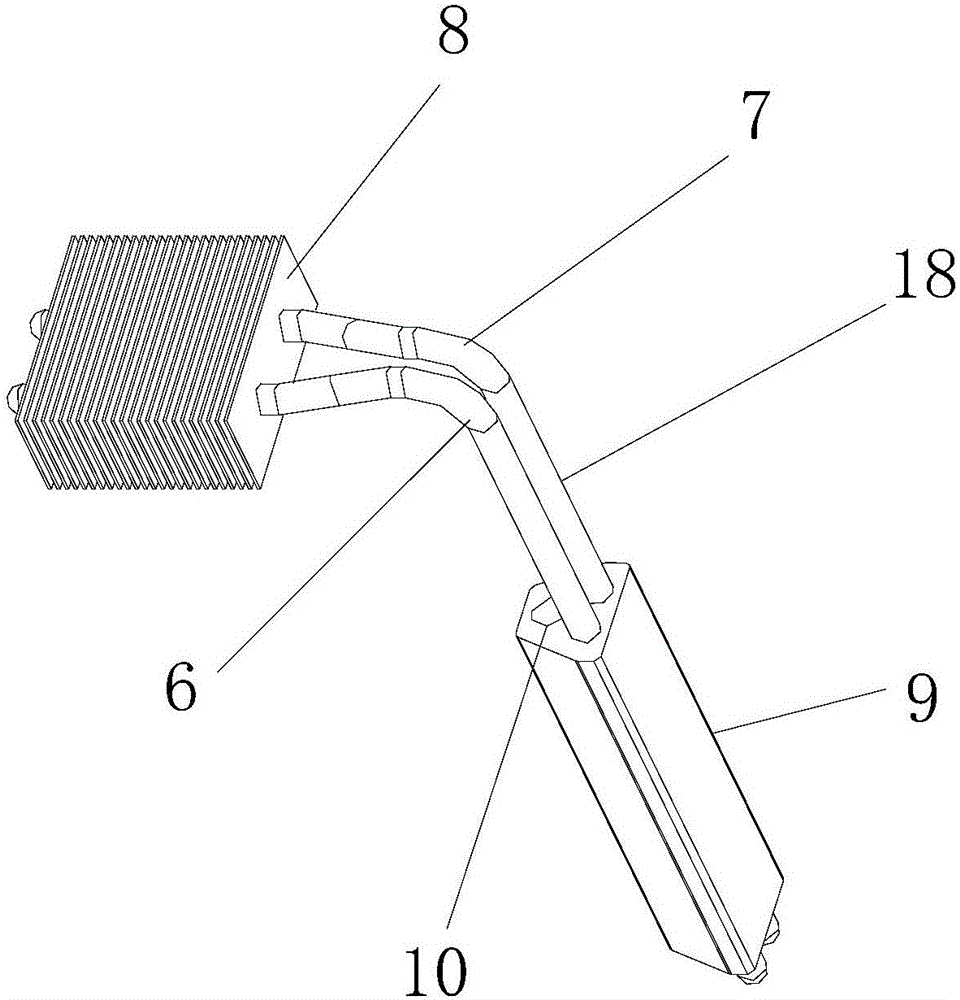

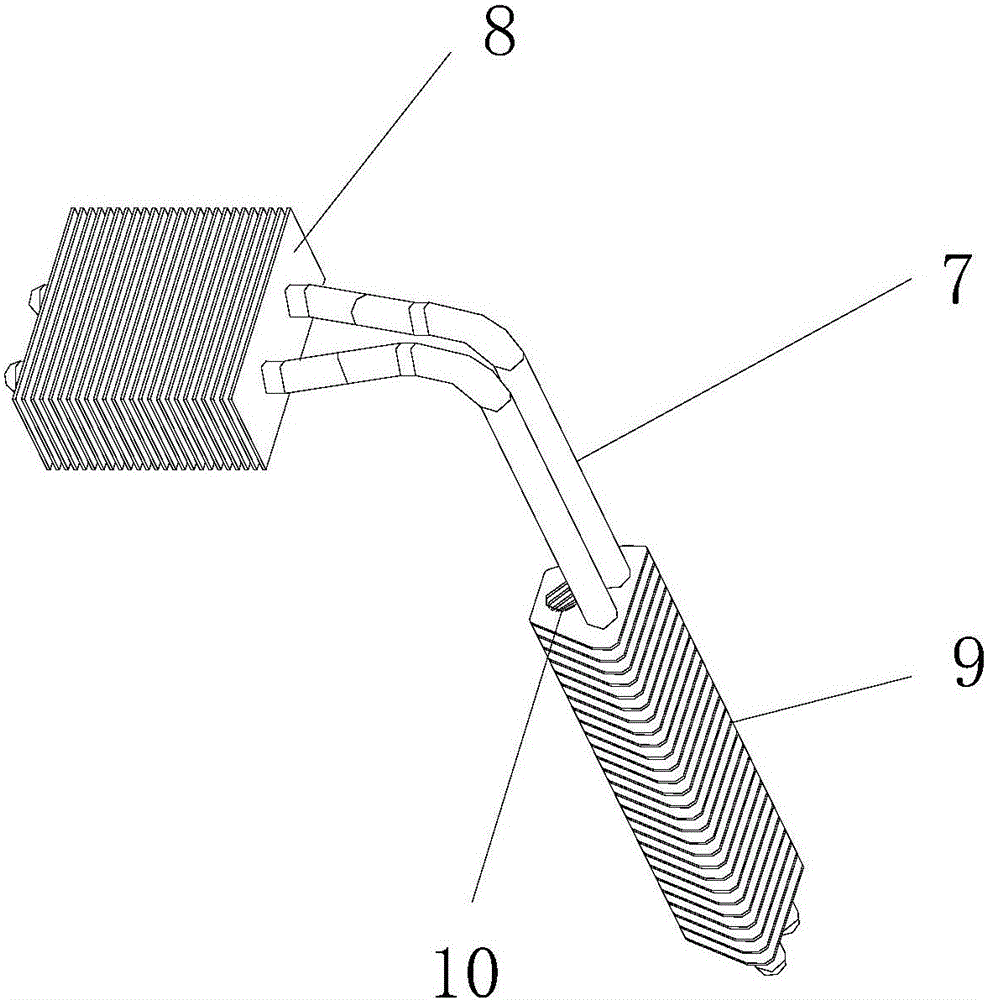

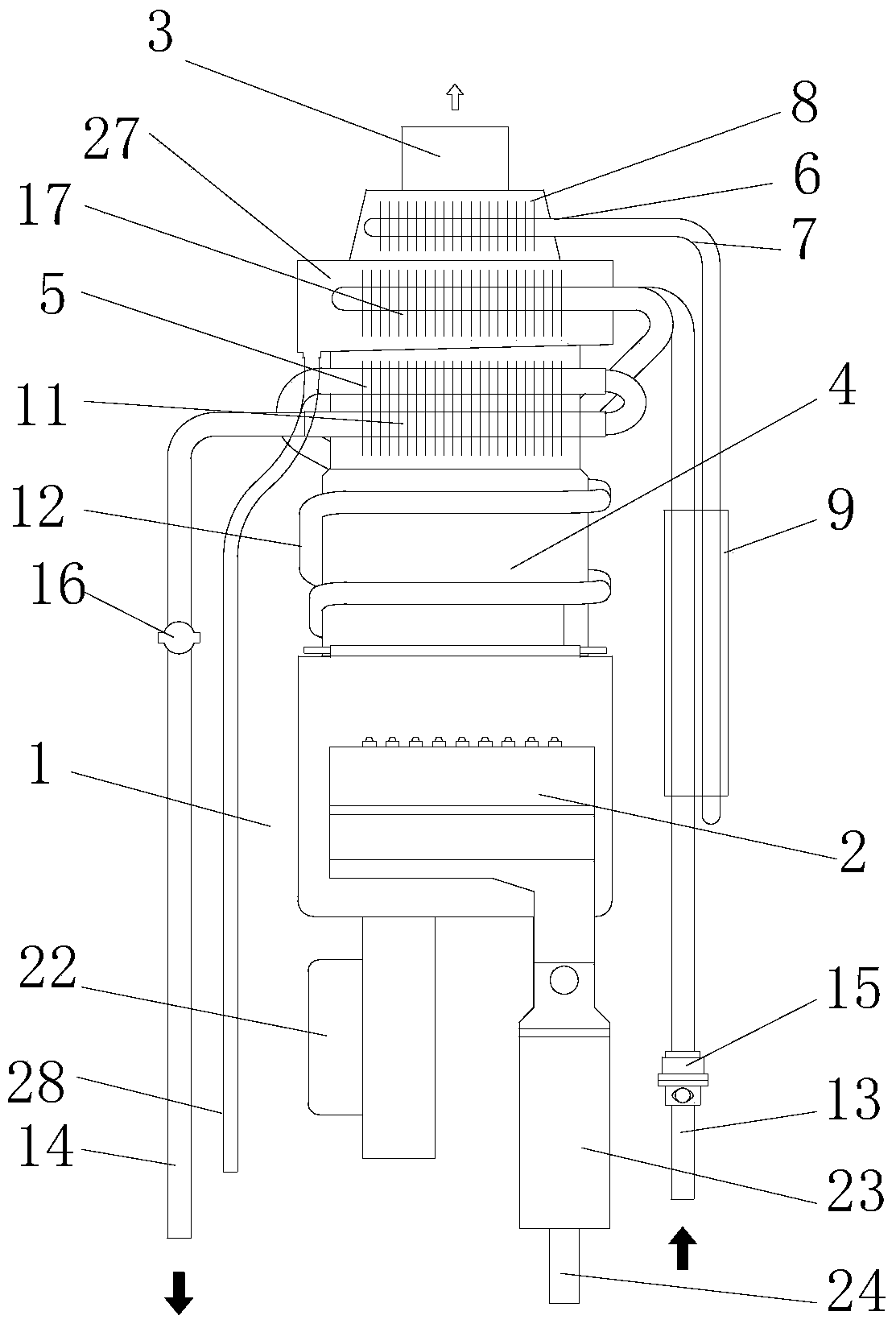

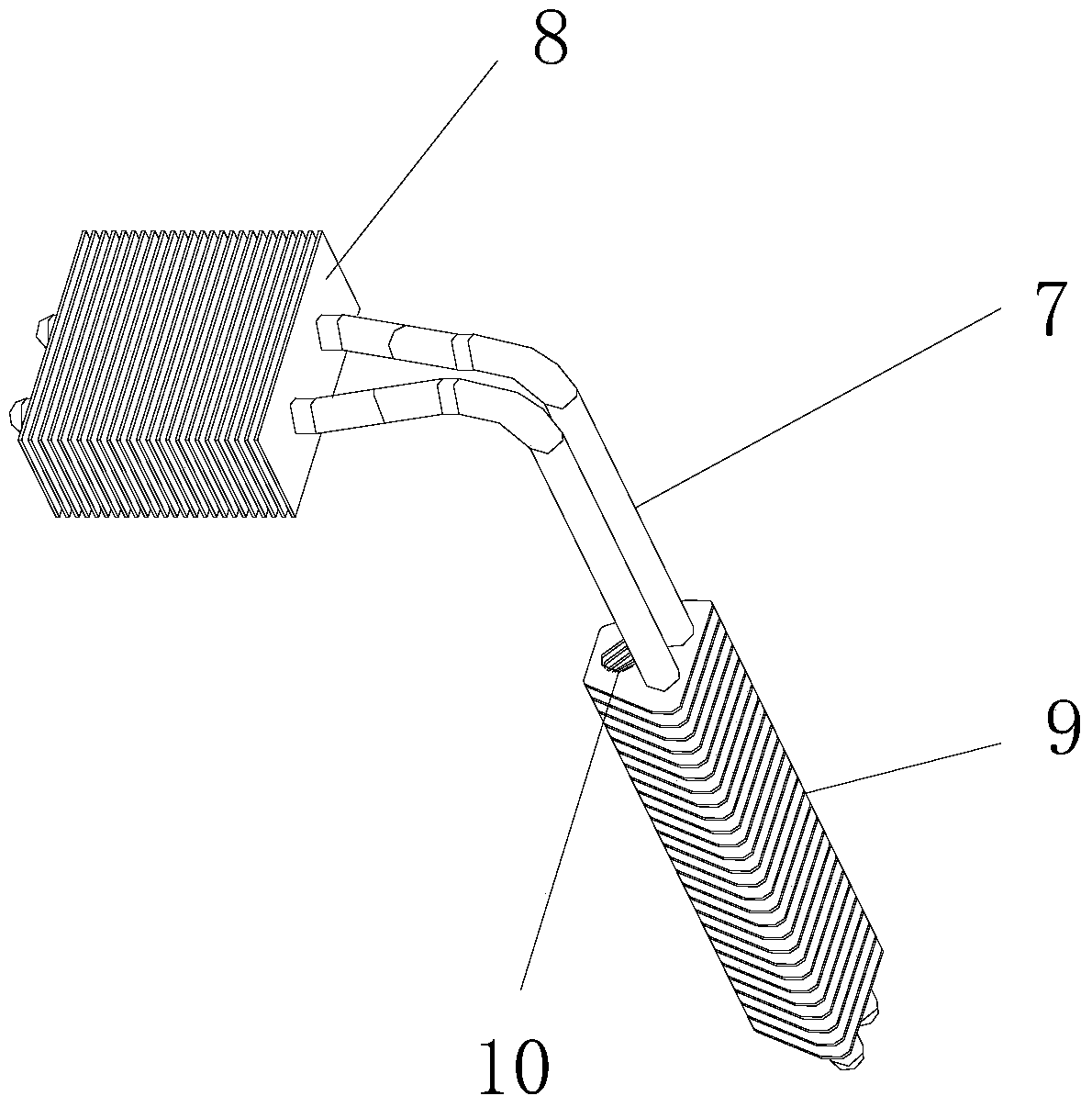

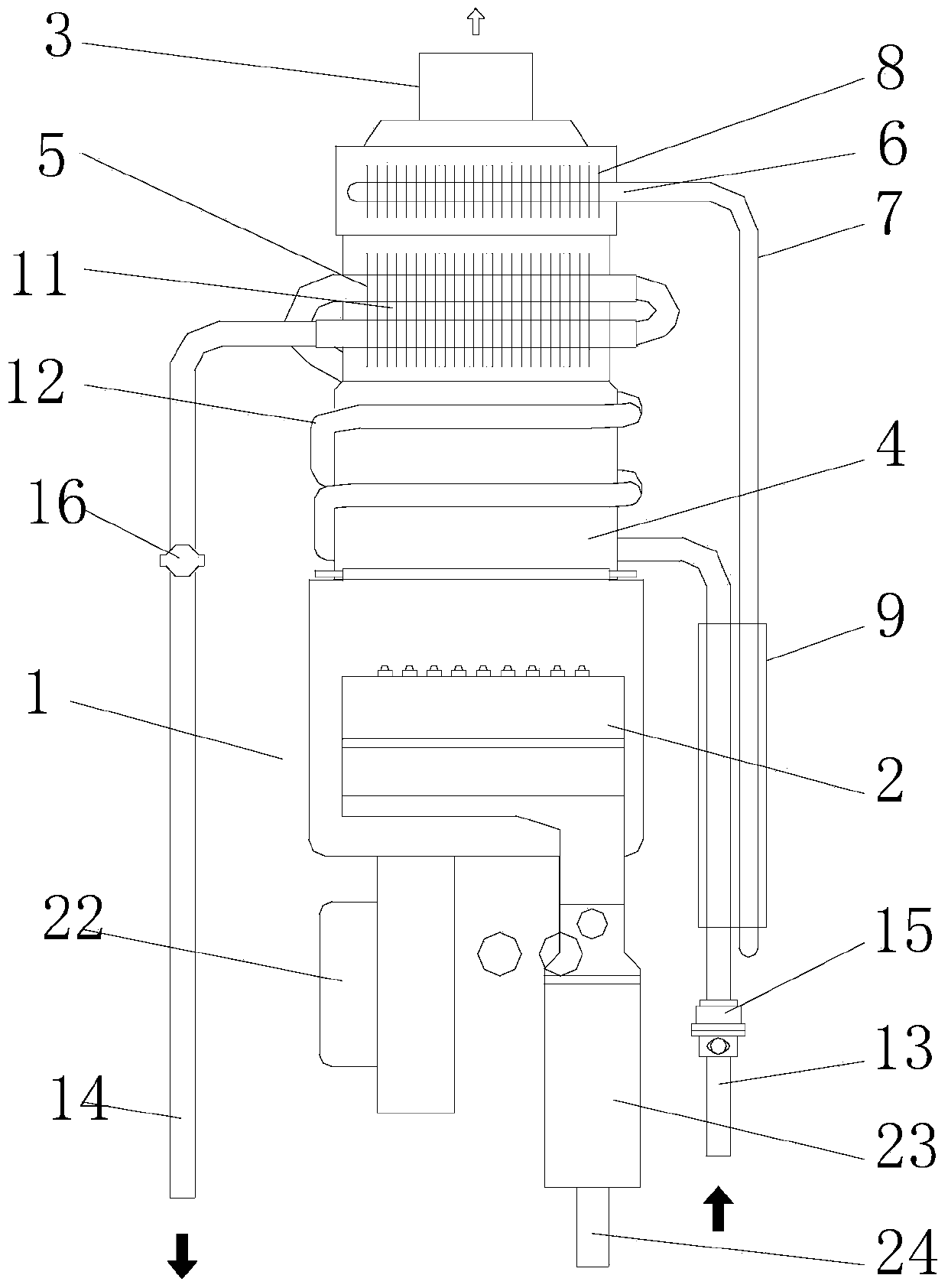

Condensing type fuel gas water heater and waste heat recycling method

ActiveCN106369805AFull waste heat recoveryHigh thermal efficiencyCombustion technology mitigationWater heatersCombustion chamberEngineering

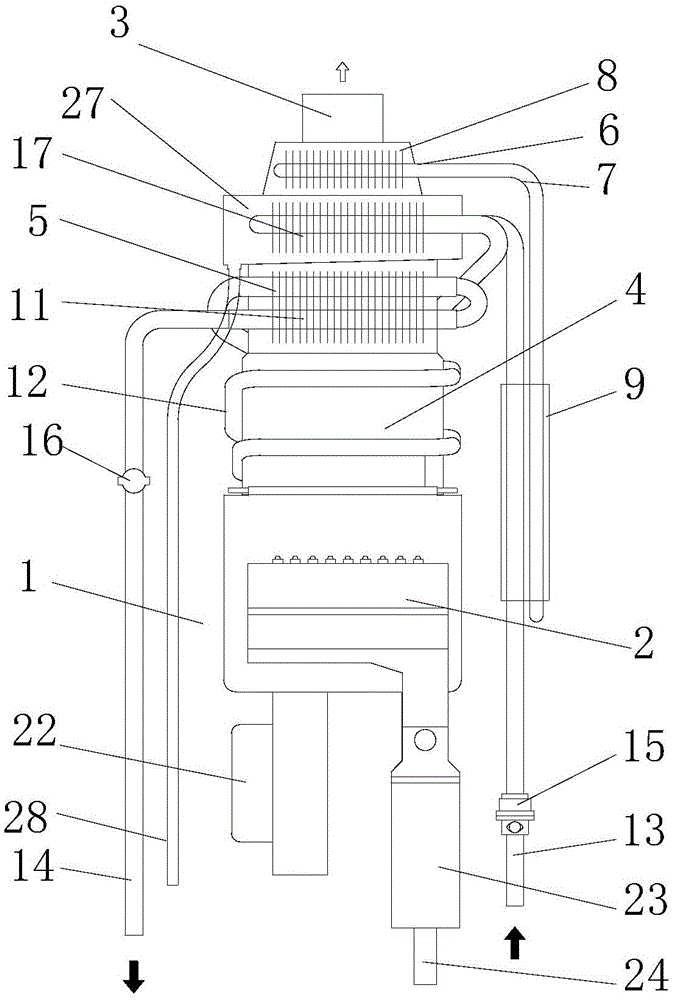

The invention relates to a condensing type fuel gas water heater. The condensing type fuel gas water heater comprises a combustion chamber, a smoke exhausting pipe, a main heat exchanger, a condensing heat exchanger and a waste heat recycling device; the waste heat recycling device comprises a heat pipe module; one end of the heat pipe module is located in the portion, between the condensing heat exchanger and the smoke exhausting pipe, of a smoke exhausting channel; and the other end of the heat pipe module is located at the water inflow end of the water heater. The waste heat recycling device further comprises a heat absorbing module and a heat releasing module; the heat absorbing module is arranged in the smoke exhausting channel; the heat releasing module is arranged outside the smoke exhausting channel; and the heat pipe module is connected with the heat absorbing module and the heat releasing module. According to the condensing type fuel gas water heater, waste heat of waste gas exhausted by the condensing type fuel gas water heater is transmitted to pre-heat inflow water of the condensing type fuel gas water heater through a heat pipe. By means of the condensing type fuel gas water heater, the waste heat of high-temperature flue gas of the condensing type fuel gas water heater can be fully recycled and used, the heat efficiency of the condensing type fuel gas water heater is improved, and meanwhile, energy conservation and environmental protection are achieved, the structure is simple, and cost is low.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

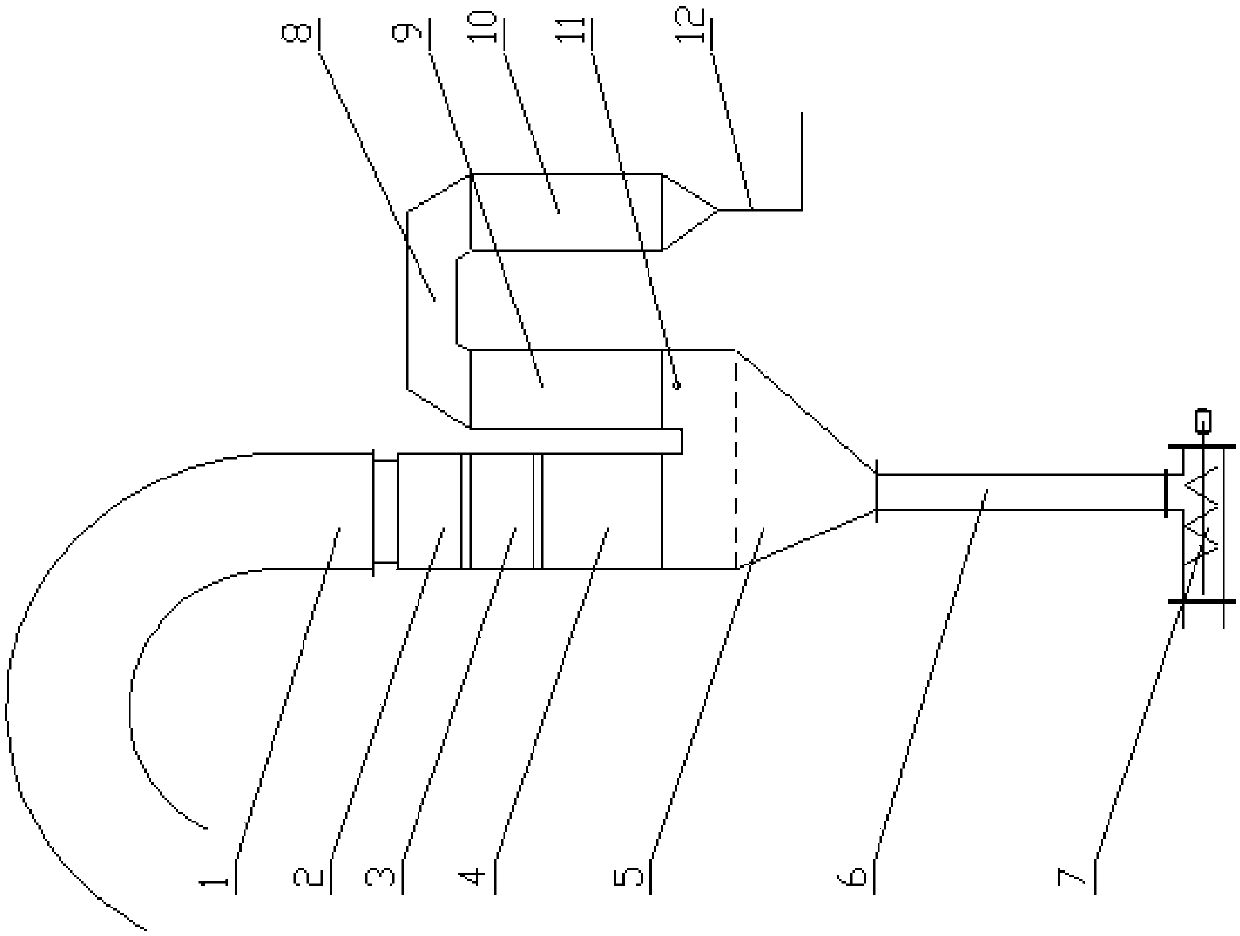

Converter dry dedusting and waste heat recycling device and method

PendingCN108048619ABurn out preventionPlay a sealing roleExhaust gas handlingIncreasing energy efficiencyBaghouseFlue

The invention discloses a converter dry dedusting and waste heat recycling device and method. The device comprises a smoke gas ingredient concentration intervention section component, a high-temperature smoke gas cooling section component, a gravity dedusting component, a cloth bag dust remover, a low-temperature smoke gas cooling section component and a mixer. An evaporative cooling flue outlet of a converter smoke outlet is sequentially connected with the smoke gas ingredient concentration intervention section component and the high-temperature smoke gas cooling section component and then isconnected with an inlet of the gravity dust removal component, an outlet of the gravity dust removal component is connected with an inlet of the cloth bag dust remover, an outlet of the cloth bag dust remover is connected with an inlet of the low-temperature smoke gas cooling section component through a pipeline, and an outlet of the low-temperature smoke gas cooling section component is connected with a smoke gas recycling mechanism. Smoke gas produced in a converter can be quite effectively purified, the temperature of smoke gas entering a cloth bag for dust removal can be controlled withina certain range, smoke gas waste heat can be absorbed, and the low-temperature waste heat recycling problem is solved.

Owner:YANGCHUN NEW STEEL CO LTD

Boiler waste heat collecting and waste gas purifying system

InactiveCN106765257AHigh recycling efficiencyAvoid accumulationCombustion technology mitigationNon-rotary device cleaningPlate heat exchangerRecuperator

The invention relates to a boiler waste heat collecting and waste gas purifying system which comprises a boiler waste heat collecting tubular heat exchanger and a waste gas purifying device, wherein the boiler waste heat collecting tubular heat exchanger communicates with the waste gas purifying device in sequence. Through an electric dust removal brush arranged in the heat exchanger and an ultrasonic atomizer arranged on the side wall of the heat exchanger, smoke is prevented from being accumulated on the heat exchange tube wall, the high heat exchange efficiency can be kept continuously, waste heat recycling is conducted sufficiently, and the recycling benefits of the waste heat system are improved; and by arranging the waste gas purifying device at an air outlet of the boiler waste heat collecting tubular heat exchanger, waste gas exhausted into the air is non-toxic and harmless, and environment pollution is avoided.

Owner:JIANGSU HUAYUE SPECIAL EQUIP

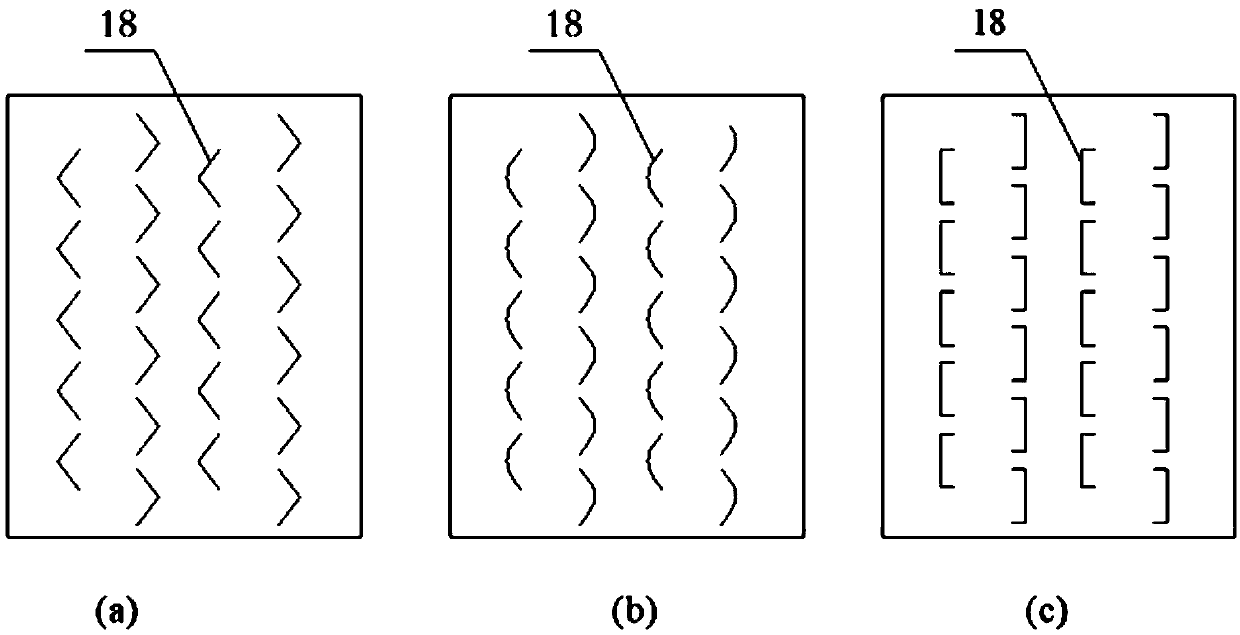

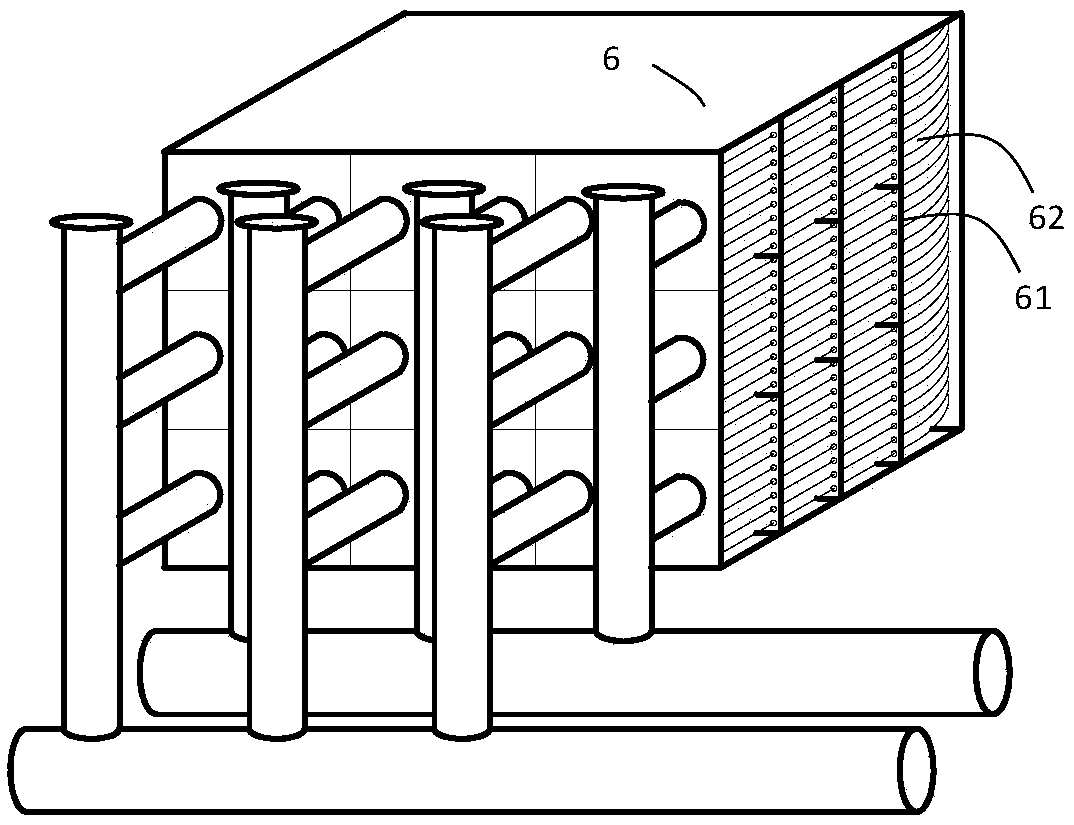

High-temperature flue gas waste heat recovery and advanced purification system

ActiveCN106989607AEfficient recovery of waste heatExtend the distribution pathIncreasing energy efficiencySteam engine plantsOrganic Rankine cycleProcess engineering

The invention discloses a high-temperature flue gas waste heat recovery and advanced purification system. The system comprises a waste heat recovery module, a power generation module, an organic Rankine cycle heat exchanger and a dust removal purification module, wherein the gas inlet end of the waste heat recovery module is connected with a high-temperature flue gas inlet, the gas outlet end of the waste heat recovery module is connected with the dust removal purification module, two sets of tube type heat exchangers in different arrangement directions are arranged in the waste heat recovery module, a heat-exchange medium pipe outlet inside the waste heat recovery module is connected with the power generation module, the power generation module and the organic Rankine cycle heat exchanger are connected in series, and steam output through the organic Rankine cycle heat exchanger is subjected to refluxing through a condenser, passes through a working medium separator and then is connected to the waste heat recovery module and a heat exchange medium pipe inlet of the organic Rankine cycle heat exchanger. According to the high-temperature flue gas waste heat recovery and advanced purification system, a water working medium and an organic working medium are adopted and combined with electrolyzed high-temperature flue gas for three-time heat exchange, the purpose of utilizing heat of high-temperature flue gas to the maximum extent is achieved, the dust removal purification module is adopted for conducting advanced purification on cooled flue gas, energy conservation and emission reduction are achieved, and the economic benefit of enterprise production is improved.

Owner:CENT SOUTH UNIV

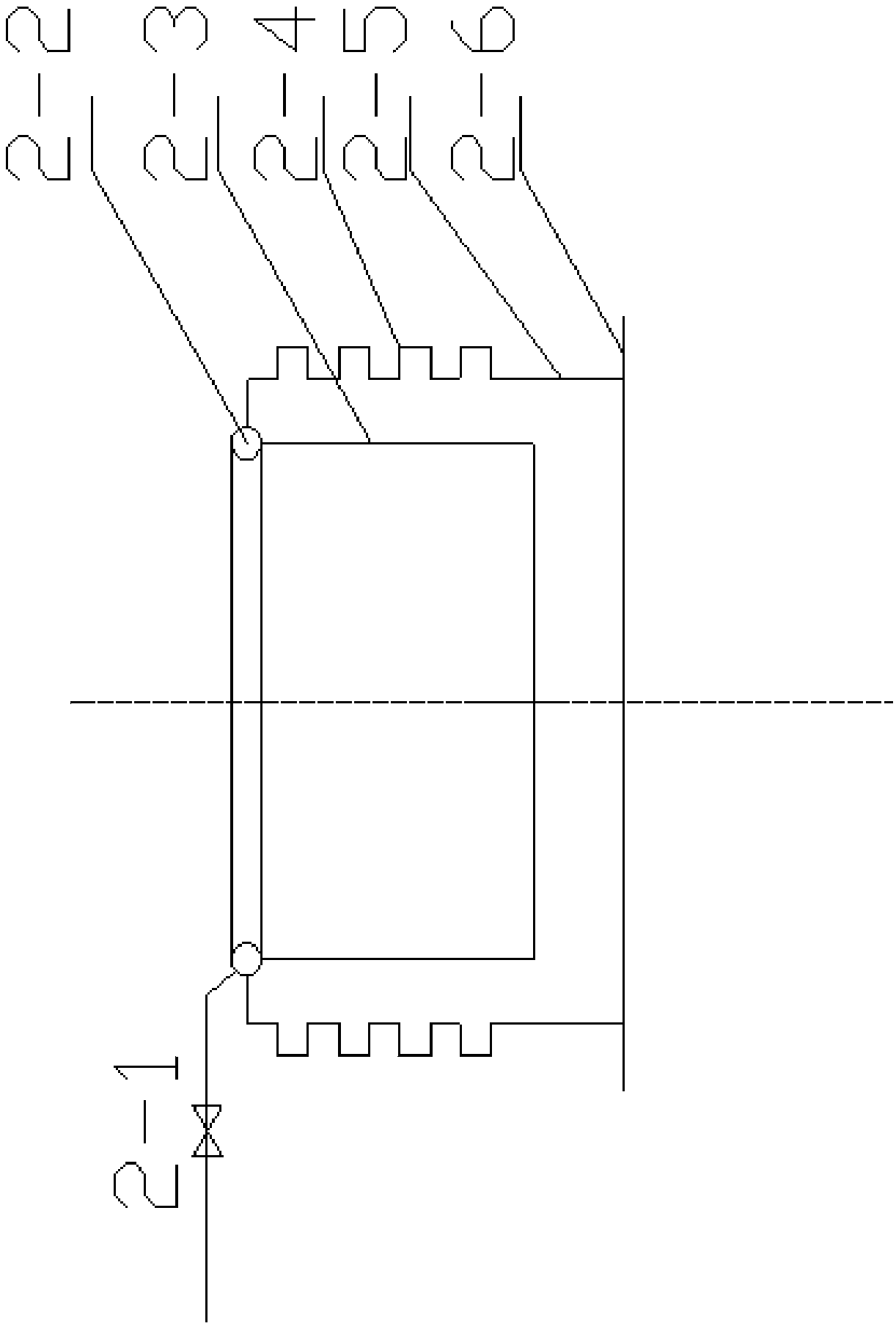

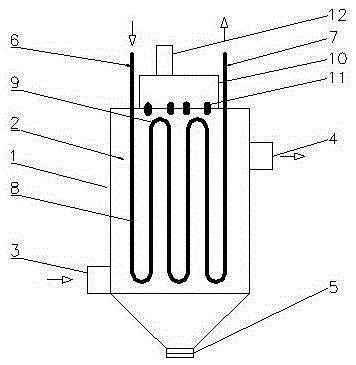

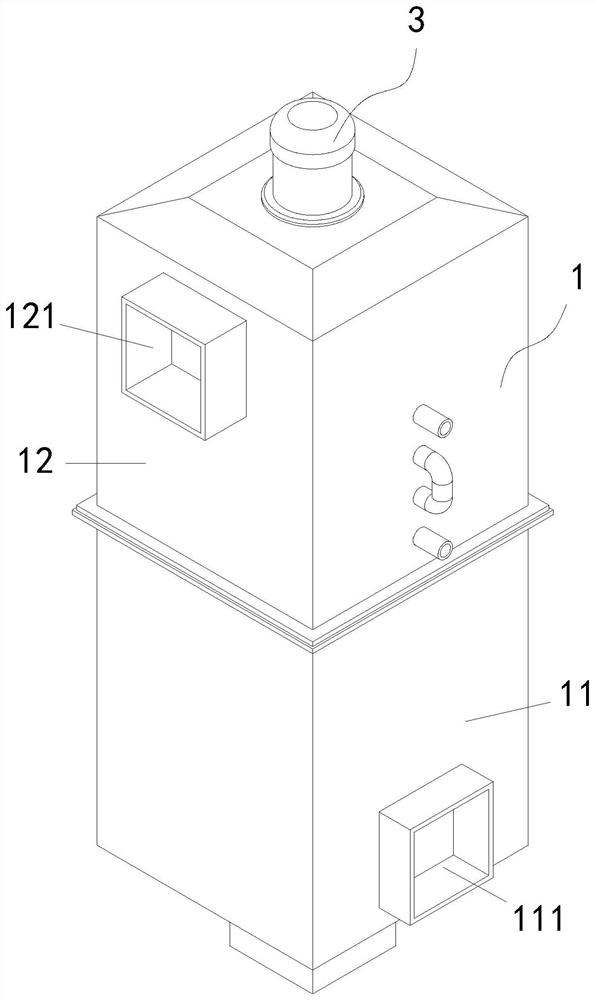

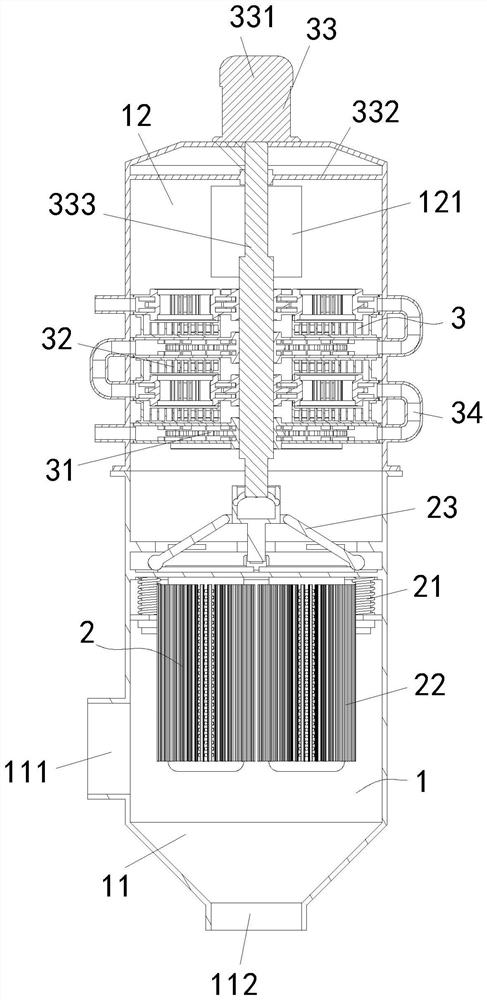

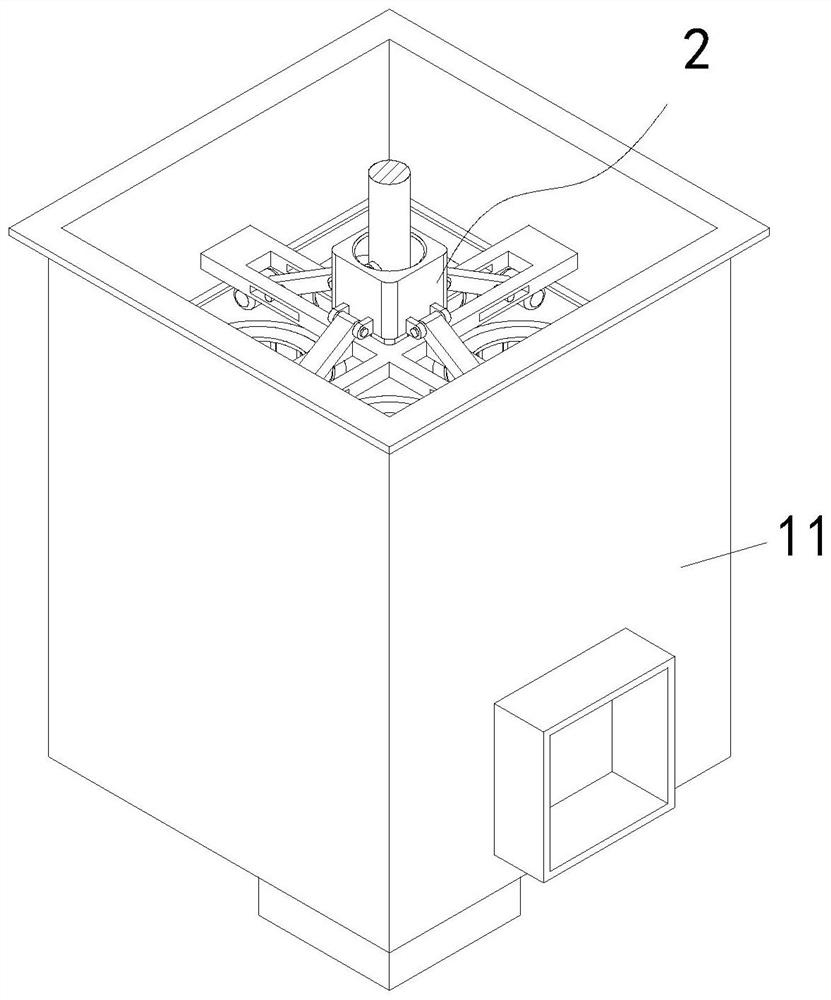

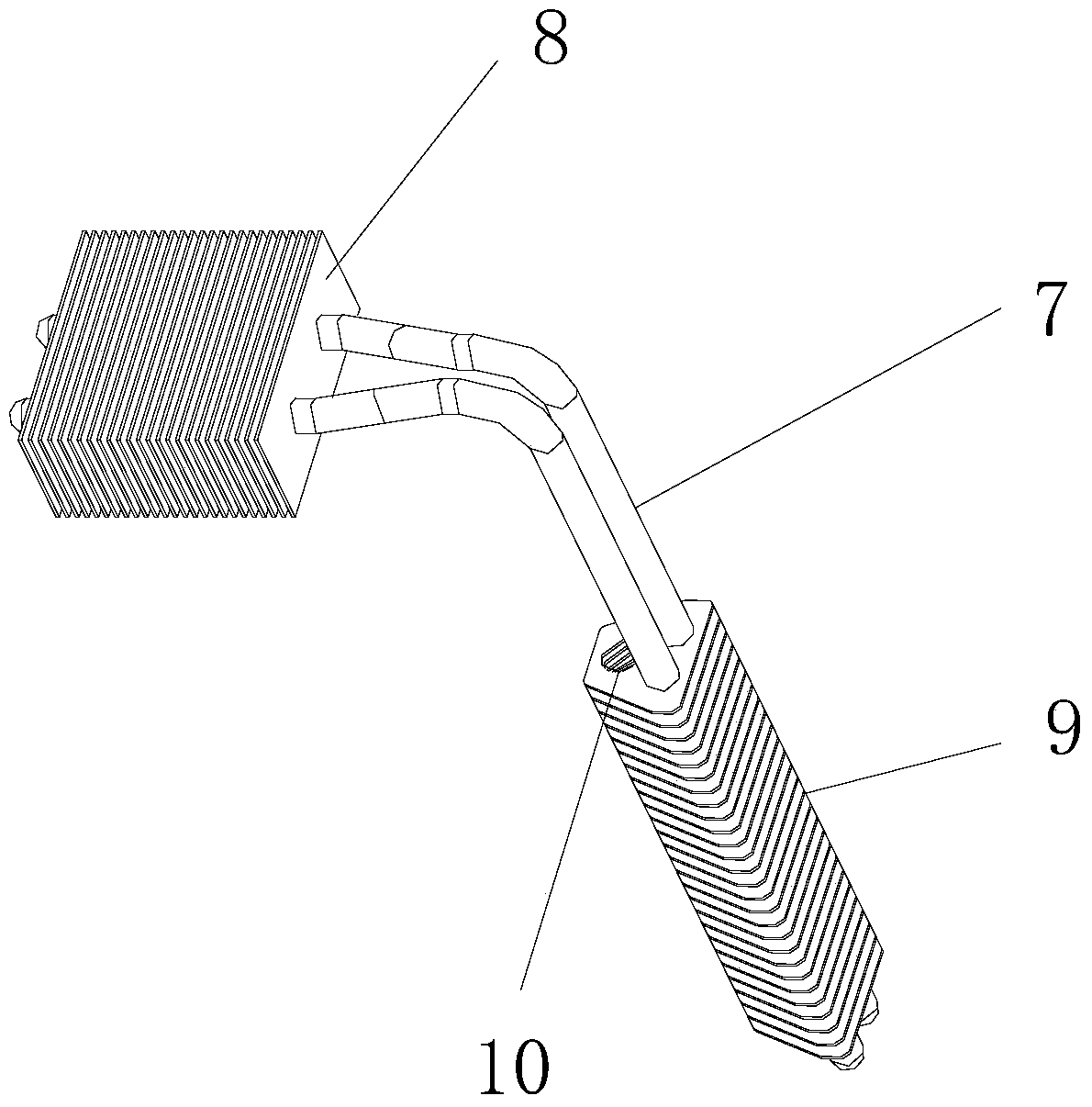

Metallurgical furnace waste heat utilizing device

InactiveCN105318738AHigh economic valueImprove heat transfer efficiencyEnergy industryIncreasing energy efficiencyVertical tubeEngineering

The invention relates to a metallurgical furnace waste heat utilizing device which comprises a heat exchange box and a heat exchange tube nest vertically arranged in the heat exchange box. The heat exchange box is provided with an air inlet, an air outlet and a dust collecting opening in the bottom of the heat exchange box. A water inlet and a water outlet of the heat exchange tube nest are located at the top of the heat exchange box, and the heat exchange tube nest comprises a plurality of vertical tubes and bent tubes used for connecting the vertical tubes. A sealed water tank is arranged at the top of the heat exchange box, and the lower portion of the sealed water tank is communicated with the interior of the heat exchange box through a plurality of water nozzles. The upper portion of each vertical tube is at least provided with one water nozzle, and an air pump is arranged on the top of the sealed water tank. According to the metallurgical furnace waste heat utilizing device, water is supplied through the sealed water tank on the top of the heat exchange box, under the assistance of the air pump, the water in the sealed water tank is sprayed out from the water nozzles so as to flush away dust on the walls of the vertical tubes of the heat exchange tube nest, high heat exchange efficiency of the heat exchange tube nest can be continuously maintained, waste heat is fully recovered, and the economic value of a waste heat system is increased.

Owner:马忠华

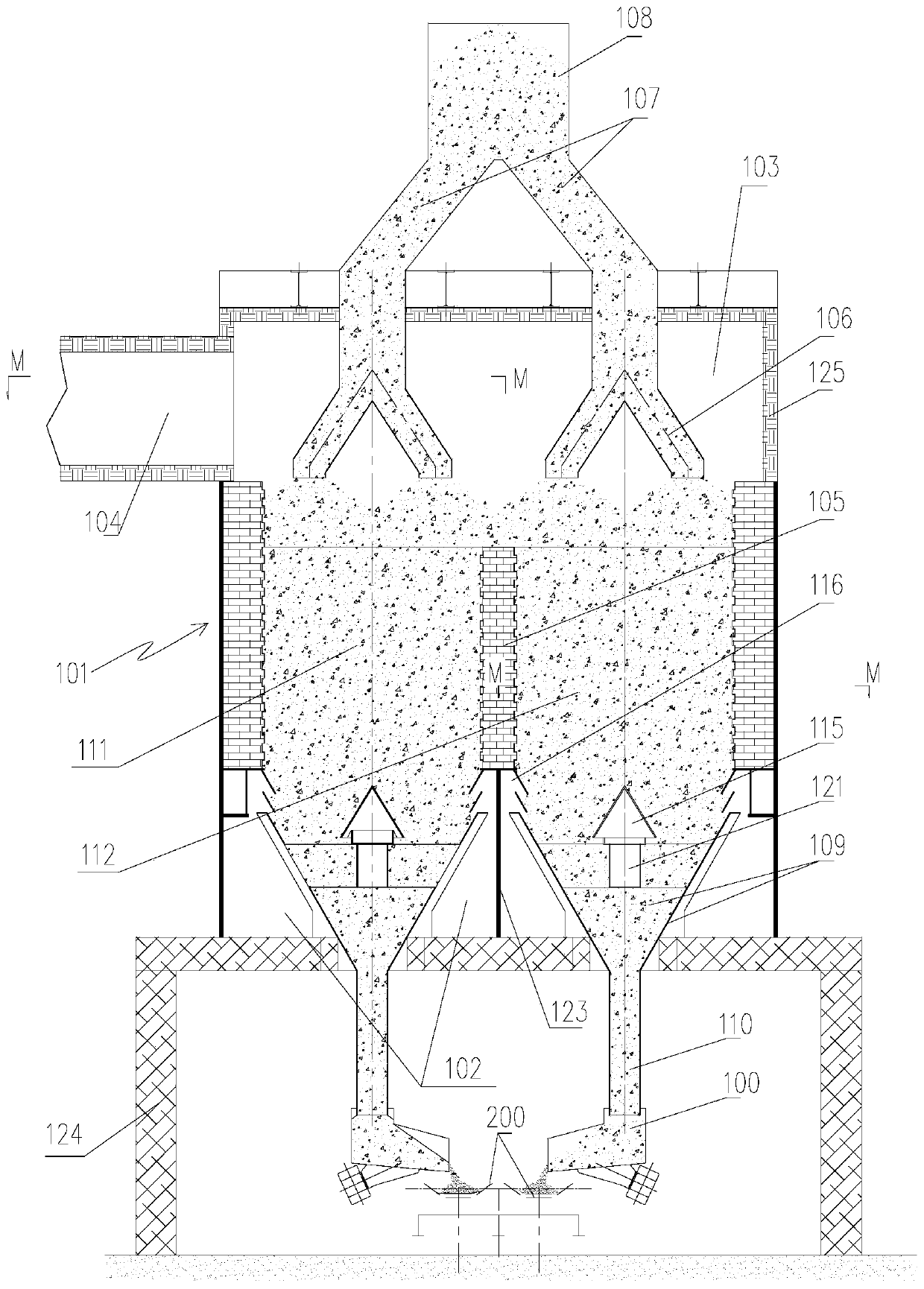

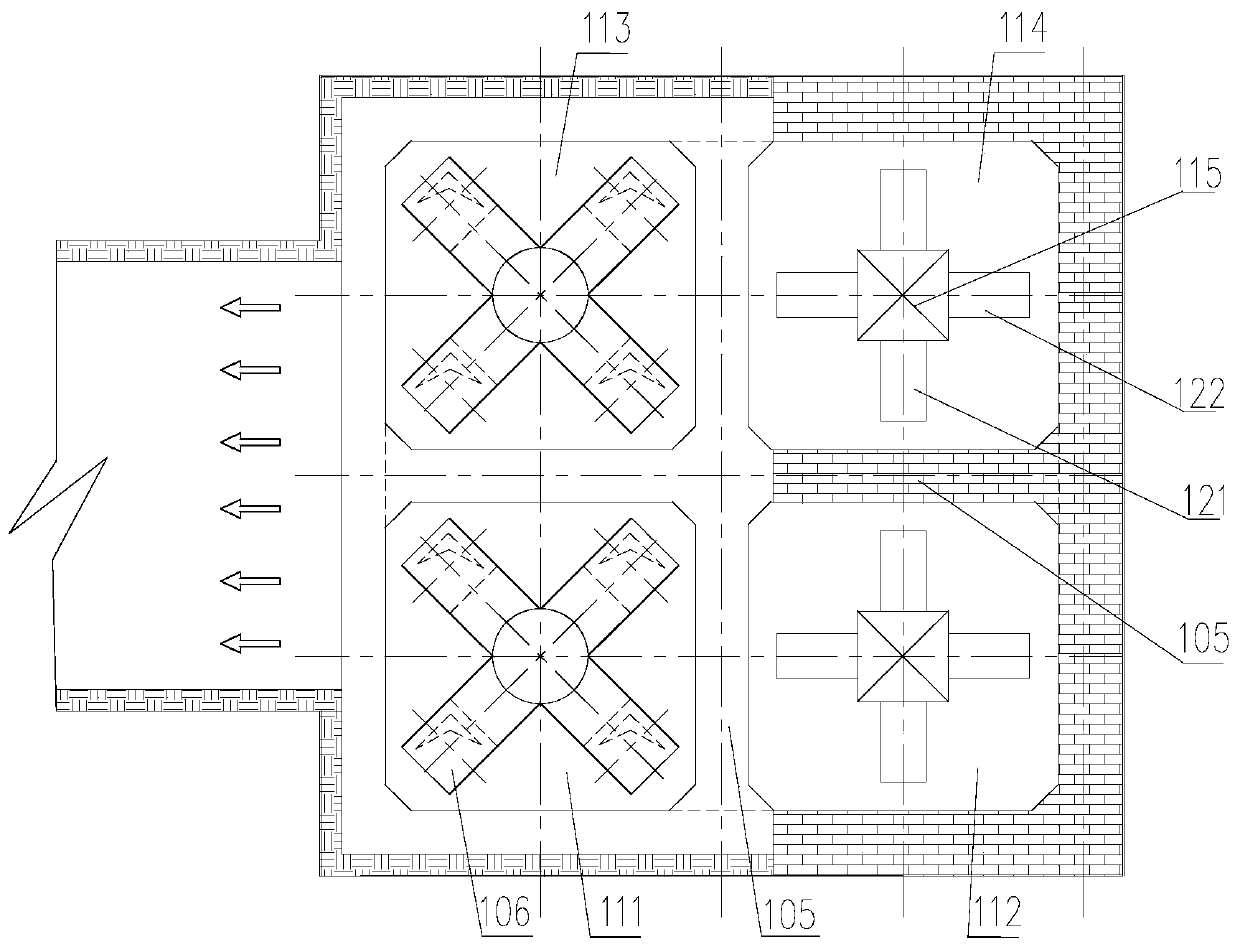

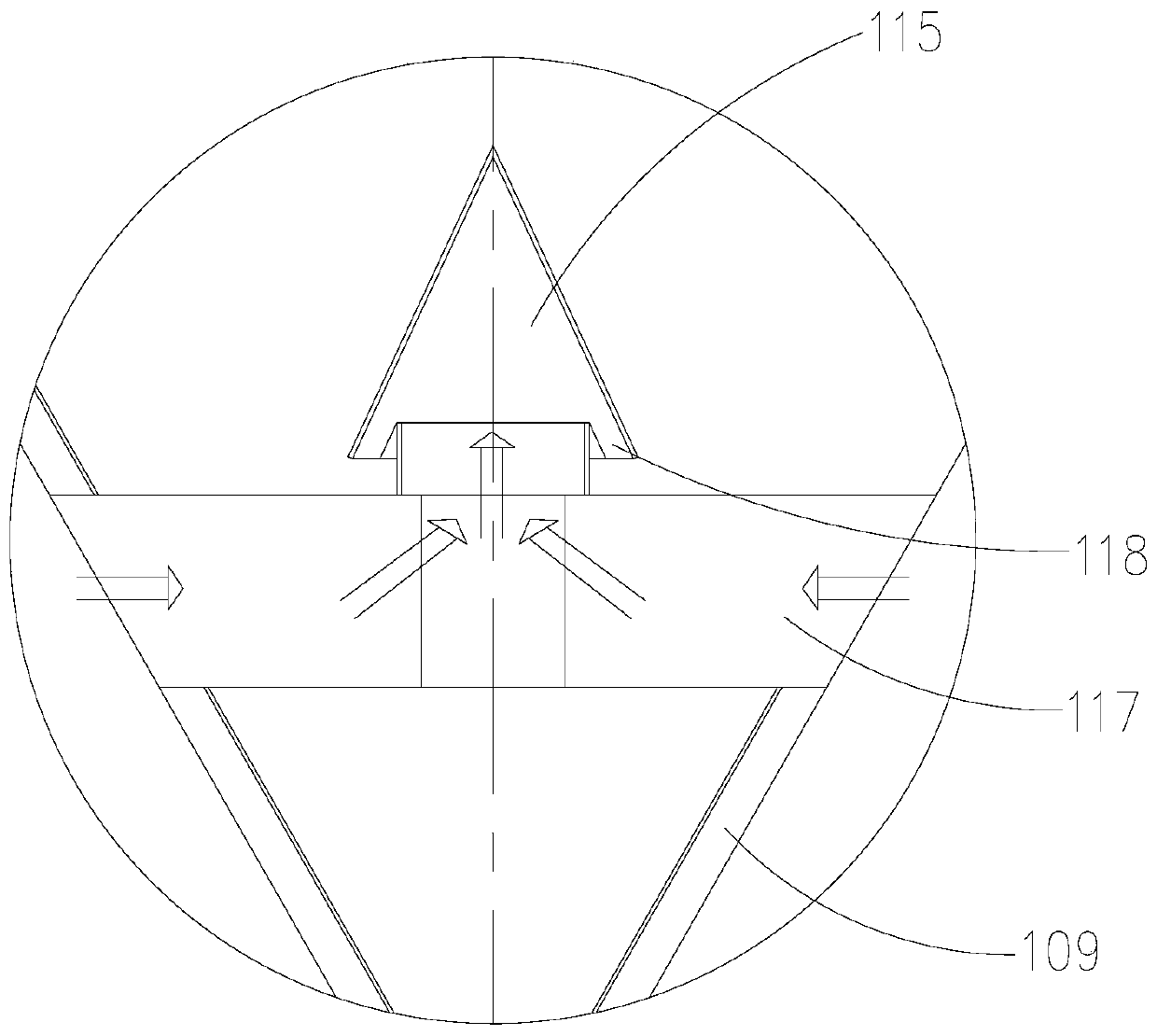

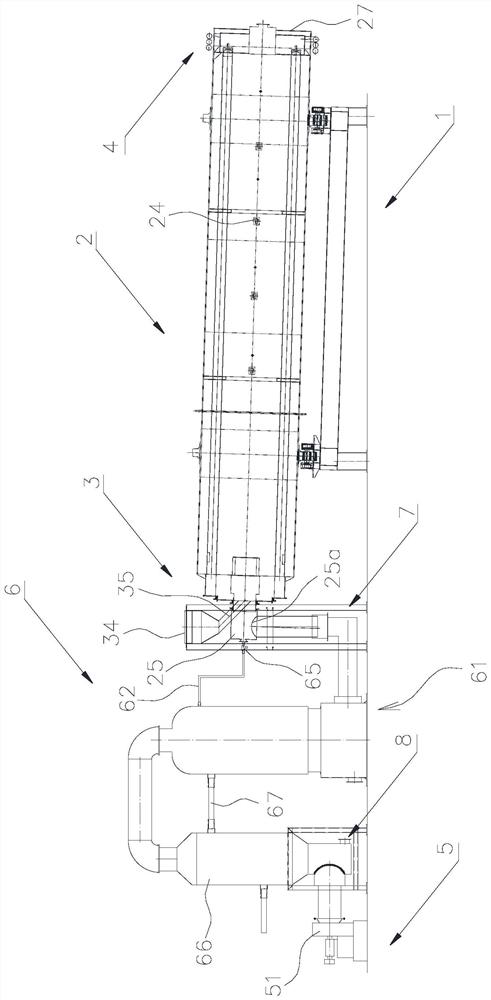

Vertical cooling kiln and mineral aggregate cooling and waste heat recovery method

PendingCN110779323AImprove uniformityRealize countercurrent heat exchangeVertical furnacesWaste heat treatmentThermodynamicsHot blast

The invention relates to the technical field of sinter cooling devices, in particular to a vertical cooling kiln and a mineral aggregate cooling and waste heat recovery method. The vertical cooling kiln comprises a kiln body, an inner ring air supply device, and an outer ring air supply device, wherein a cooling air supply chamber is arranged at the bottom of the kiln body, a hot air concentrationchamber is arranged at the top of the kiln body, and at least one cooling unit chamber is arranged between the cooling air supply chamber and the hot air concentration chamber; the cooling air supplychamber is used for providing cooling air to the cooling unit chambers, and the hot air concentration chamber is used for communicating with a hot air delivery channel; the inner ring air supply device is used for making the cooling air flow to the periphery from the centers of the cooling unit chambers; and an outer ring air inlet of the outer ring air supply device communicates with the coolingair supply chamber, and the outer ring air supply device is used for making the cooling air flow from the periphery of the cooling unit chambers to the centers. According to the vertical cooling kilnand the method, the uniformity of air supply into the cooling unit chambers can be improved, the uniform cooling of a mineral aggregate is realized, and the waste heat recovery efficiency is improved.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

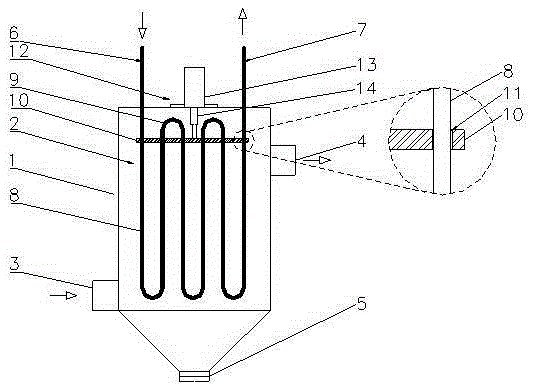

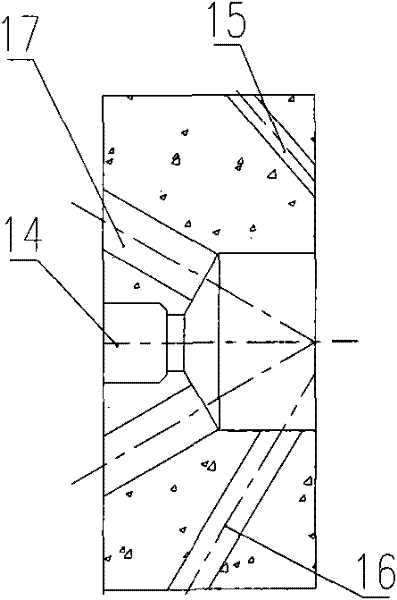

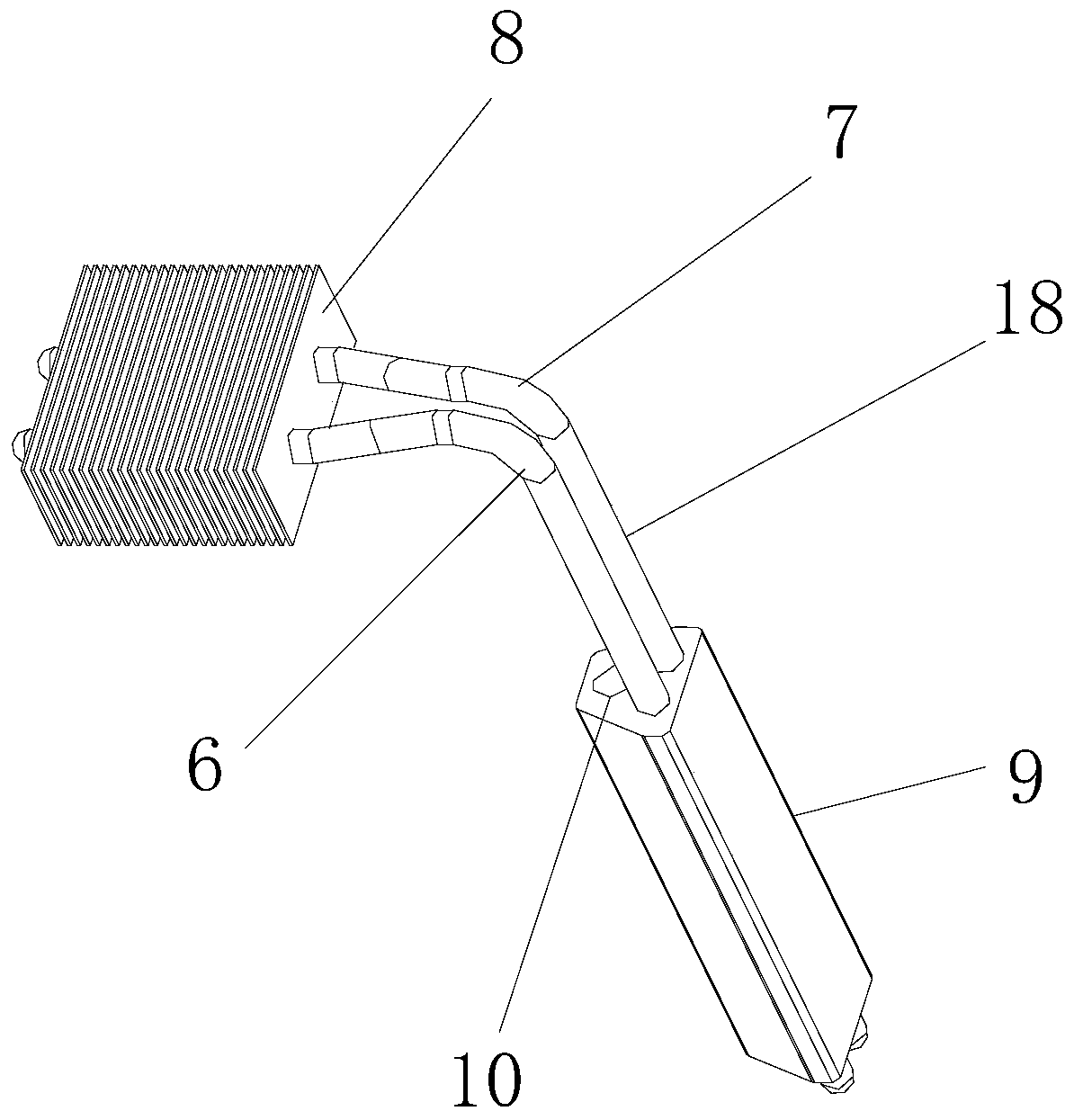

High-temperature flue gas waste heat utilizing device for metallurgical furnace

InactiveCN105318737APrevent stuck phenomenonHigh economic valueIncreasing energy efficiencyIncrustation removal devicesHydraulic cylinderVertical tube

The invention relates to a high-temperature flue gas waste heat utilizing device for a metallurgical furnace. The high-temperature flue gas waste heat utilizing device for the metallurgical furnace comprises a heat exchanging box and a heat exchanging tube nest. A dust removing plate is arranged outside the heat exchanging tube nest in a sleeving mode and is provided with a plurality of through holes. Vertical tubes of the heat exchanging tube nest are arranged in the through holes in a penetrating mode and are connected with the through holes of the dust removing plate in a sliding mode. A hydraulic cylinder is fixedly arranged at the top of the heat exchanging box, and a cylinder barrel of the hydraulic cylinder is fixed to the top of the heat exchanging box. A piston rod of the hydraulic cylinder penetrates through the top of the heat exchanging box and is fixedly connected with the dust removing plate arranged inside the heat exchanging box. According to the high-temperature flue gas waste heat utilizing device for the metallurgical furnace, the hydraulic cylinder drives the dust removing plate to move up and down, and flue gas on the tube walls of the vertical tubes of the heat exchanging tube nest is removed, so that the high heat exchanging efficiency of the high-temperature flue gas waste heat utilizing device for the metallurgical furnace can be maintained continuously, the waste heat recovery is fully conducted, and the economic value of a waste heat system is improved; the vertical tubes of the heat exchanging tube nest are in clearance fit with the through holes of the dust removing plate, so that the phenomenon that the dust removing plate is stuck during the up and down operation process can be prevented.

Owner:马忠华

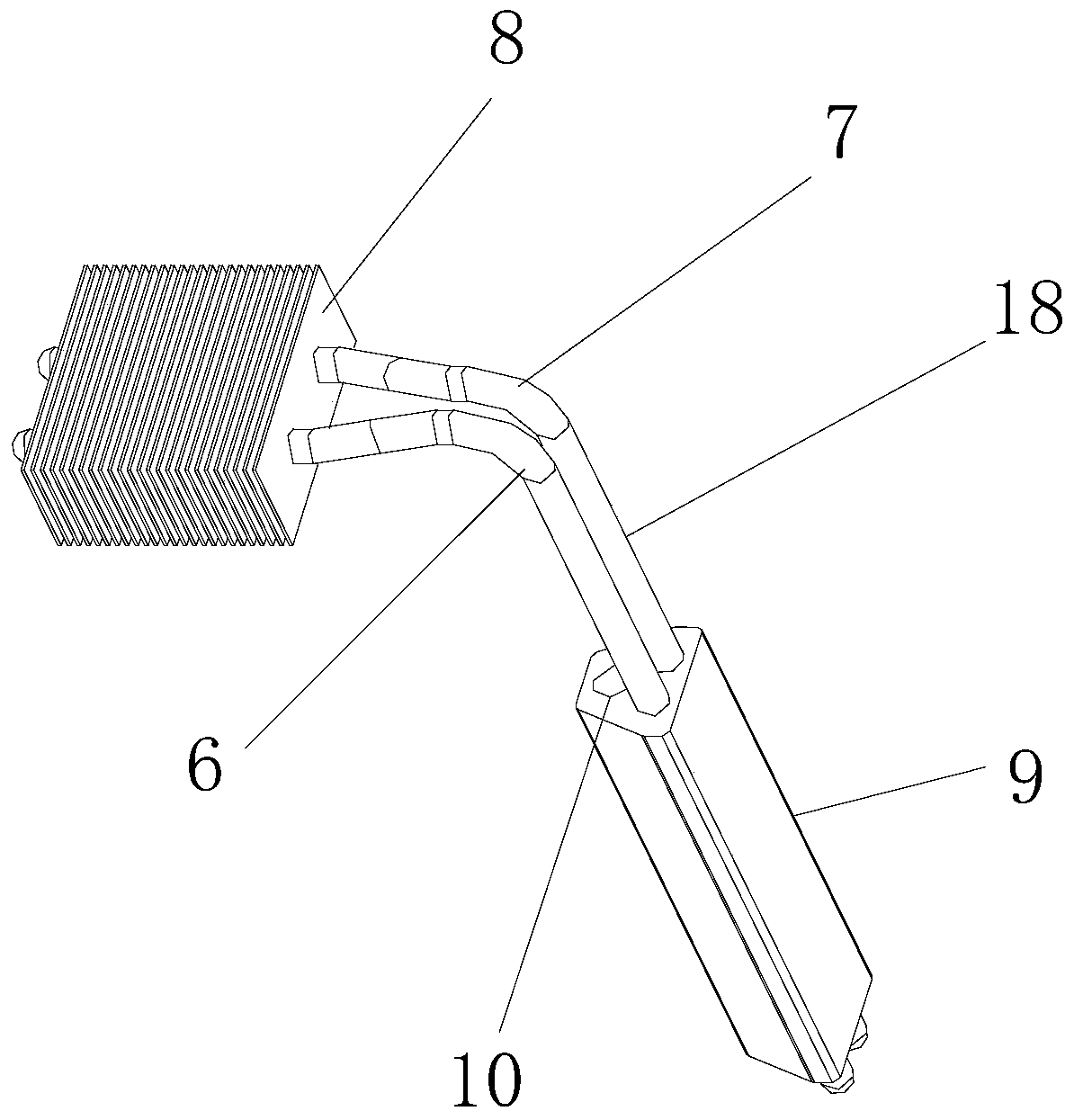

Gas water heater and waste heat recycle method

ActiveCN106369825AFull waste heat recoveryHigh thermal efficiencyFluid heatersIndirect heat exchangersCombustion chamberEngineering

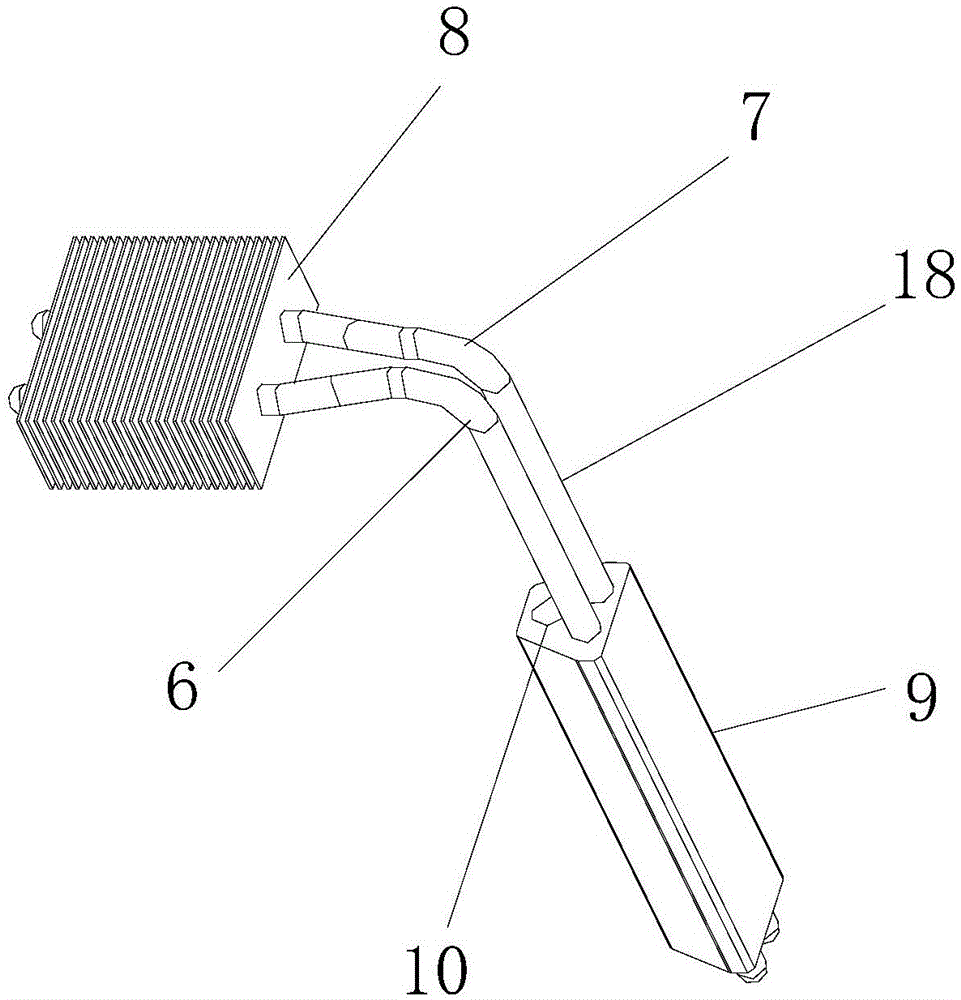

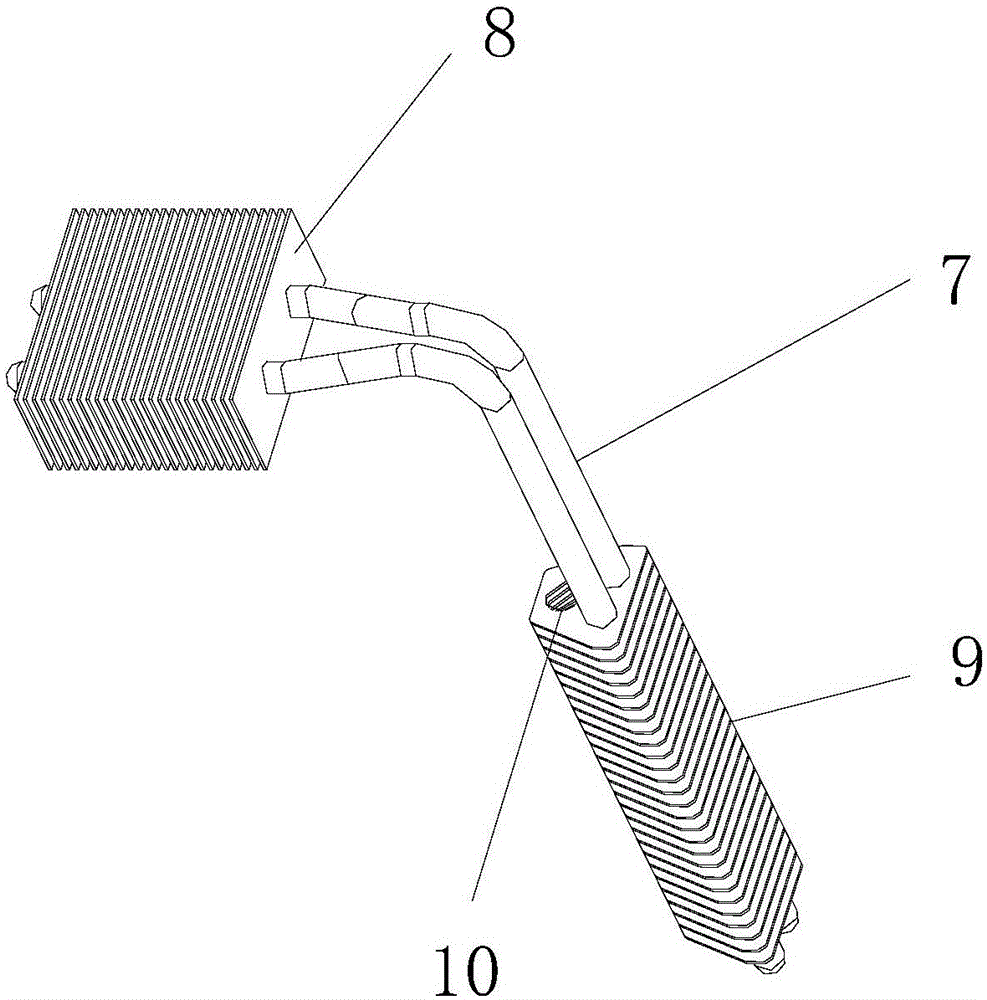

The invention relates to a gas water heater and a waste heat recycle method. The gas water heater comprises a combustion chamber, a smoke emission pipe, a heat exchange passage, a main heat exchanger and a waste heat recycle device, wherein the heat exchange passage communicates with the combustion chamber and the smoke emission pipe; the waste heat recycle device comprises a heat pipe module; one end of the heat pipe module is located in the heat exchange passage, and the other end of the heat pipe module is located at the water inlet end of the water heater; the waste heat recycle device further comprises a heat absorption module and a heat emission module; the heat absorption module is arranged in the heat exchange passage; the heat emission module is arranged on the outer part of the heat exchange passage; and the heat pipe module is connected with the heat absorption module and the heat emission module. According to the gas water heater and the waste heat recycle method, waste heat of waste gas emitted by the gas water heater is transmitted to preheat inlet water of the gas water heater by utilizing the heat pipe. By adopting the gas water heater and the waste heat recycle method, the waste heat of high-temperature smoke of the gas water heater can be fully recycled; the heat efficiency of the gas water heater is improved; meanwhile, the gas water heater is energy-saving and environment-friendly; the structure is simple; and cost is low.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

Condensing gas water heater and waste heat recovery method

ActiveCN106369805BFull waste heat recoveryHigh thermal efficiencyCombustion technology mitigationWater heatersCombustion chamberExhaust pipe

The invention relates to a condensing type fuel gas water heater. The condensing type fuel gas water heater comprises a combustion chamber, a smoke exhausting pipe, a main heat exchanger, a condensing heat exchanger and a waste heat recycling device; the waste heat recycling device comprises a heat pipe module; one end of the heat pipe module is located in the portion, between the condensing heat exchanger and the smoke exhausting pipe, of a smoke exhausting channel; and the other end of the heat pipe module is located at the water inflow end of the water heater. The waste heat recycling device further comprises a heat absorbing module and a heat releasing module; the heat absorbing module is arranged in the smoke exhausting channel; the heat releasing module is arranged outside the smoke exhausting channel; and the heat pipe module is connected with the heat absorbing module and the heat releasing module. According to the condensing type fuel gas water heater, waste heat of waste gas exhausted by the condensing type fuel gas water heater is transmitted to pre-heat inflow water of the condensing type fuel gas water heater through a heat pipe. By means of the condensing type fuel gas water heater, the waste heat of high-temperature flue gas of the condensing type fuel gas water heater can be fully recycled and used, the heat efficiency of the condensing type fuel gas water heater is improved, and meanwhile, energy conservation and environmental protection are achieved, the structure is simple, and cost is low.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

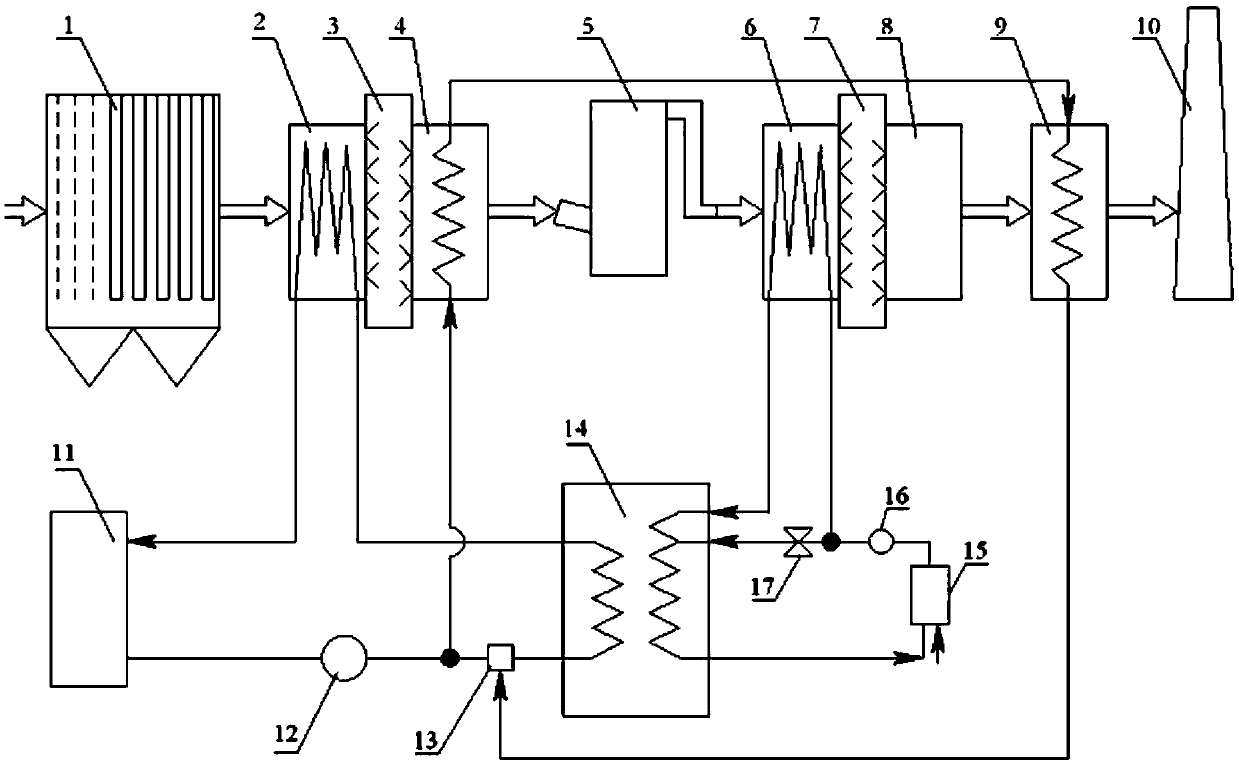

Coal-fired flue gas ultra-low emission and waste-heat utilization combined system and running method thereof

PendingCN109539293ARealize the effect of ultra-low emissionAchieve moisture recoveryHeat pumpsRecuperative heat exchangersMoistureHeat pump

The invention provides a coal-fired flue gas ultra-low emission and waste-heat utilization combined system and a running method thereof. The system includes a flue gas and air system, a heat supply network water system and a circulating water system. The flue gas and air system includes a dust remover, a high temperature waste heat recovery device, a desulfurization tower, a low temperature wasteheat recovery device, a reheater and the like which are sequentially connected through a flue gas and air passage. The high temperature waste heat device is connected to the heat supply network watersystem through a pipeline arranged between the high temperature waste heat device and the heat supply network water system. The heat supply network water system and the circulating water system exchange heat through a heat pump, so that the circulating water system and a low temperature and low grade heat source of flue gas of an outlet of the desulfurization tower are deeply utilized. The flue gas of an outlet of a boiler air pre-heater is subjected to dedusting, cooling, desulfuration and cooling again, phase change agglomeration, turbulent agglomeration and other effects are used for deepremoval of fine particles, moisture and soluble salts in the flue gas, and the flue gas ultra-low emission is achieved during flue gas and steam turbine condenser circulating water waste heat using. The coal-fired flue gas ultra-low emission and waste-heat utilization combined system and the running method have the advantages that the low-grade energy cascade utilization efficiency is low, and ultra-low emission of pollutants in the flue gas is achieved.

Owner:TSINGHUA UNIV

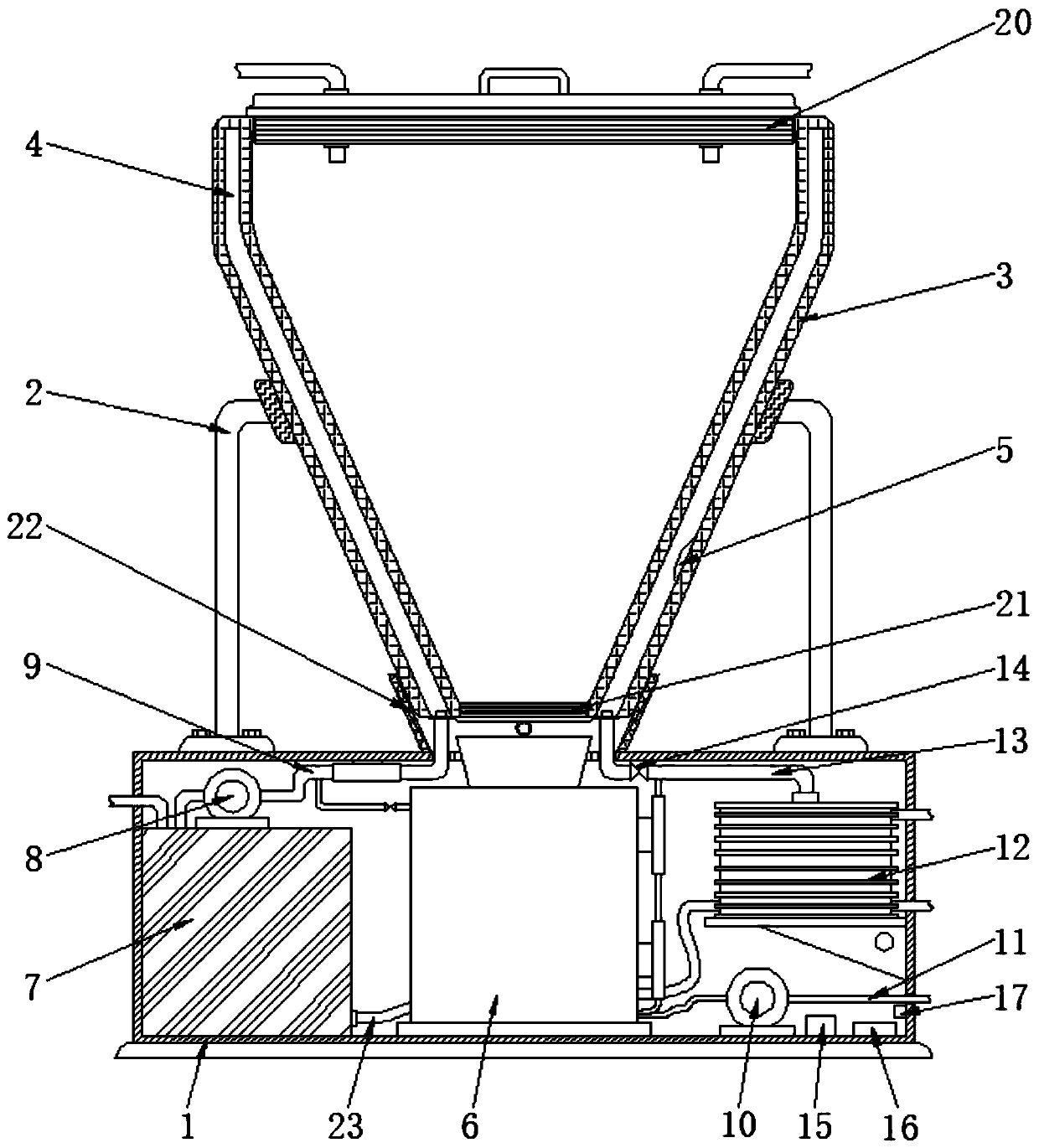

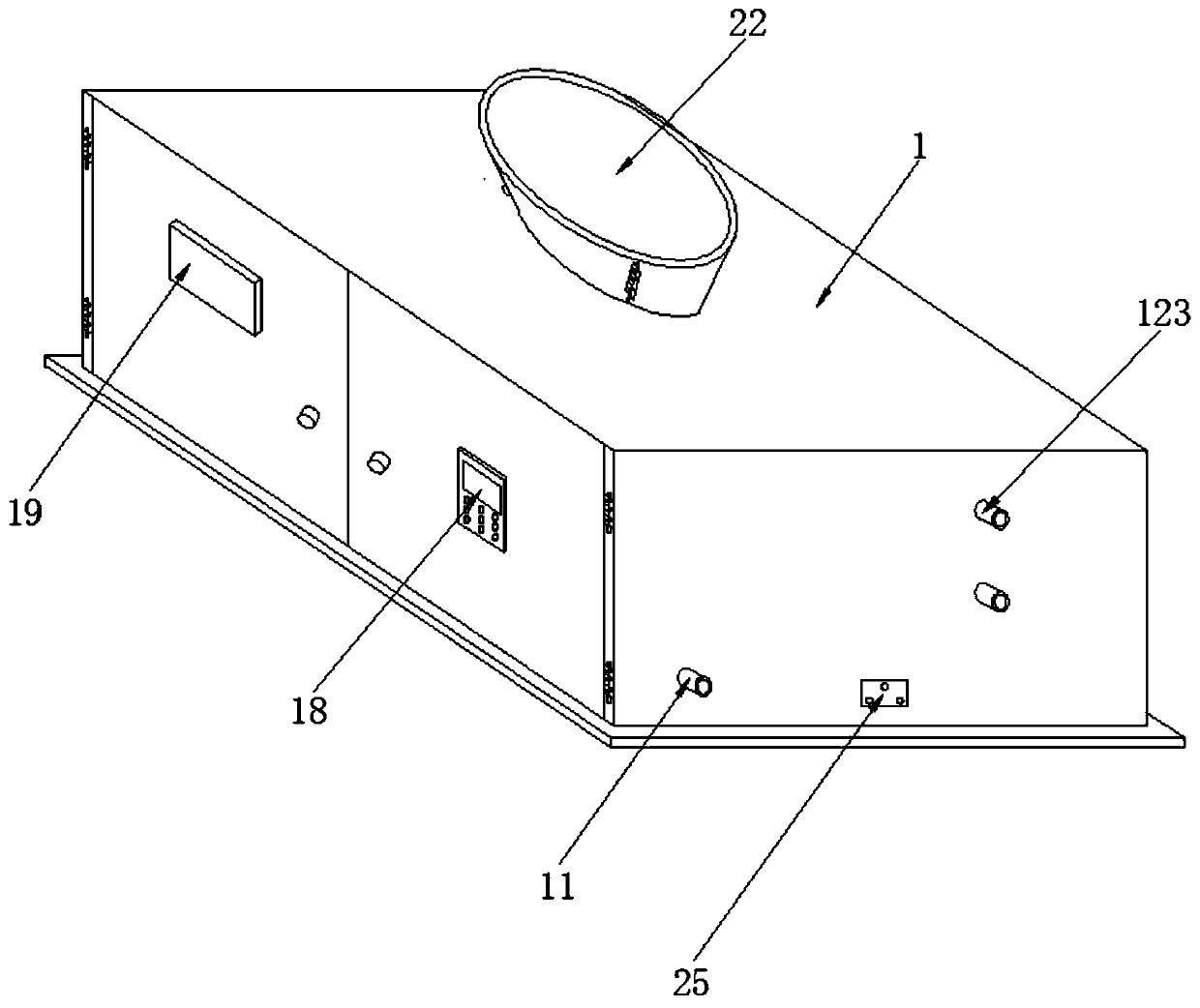

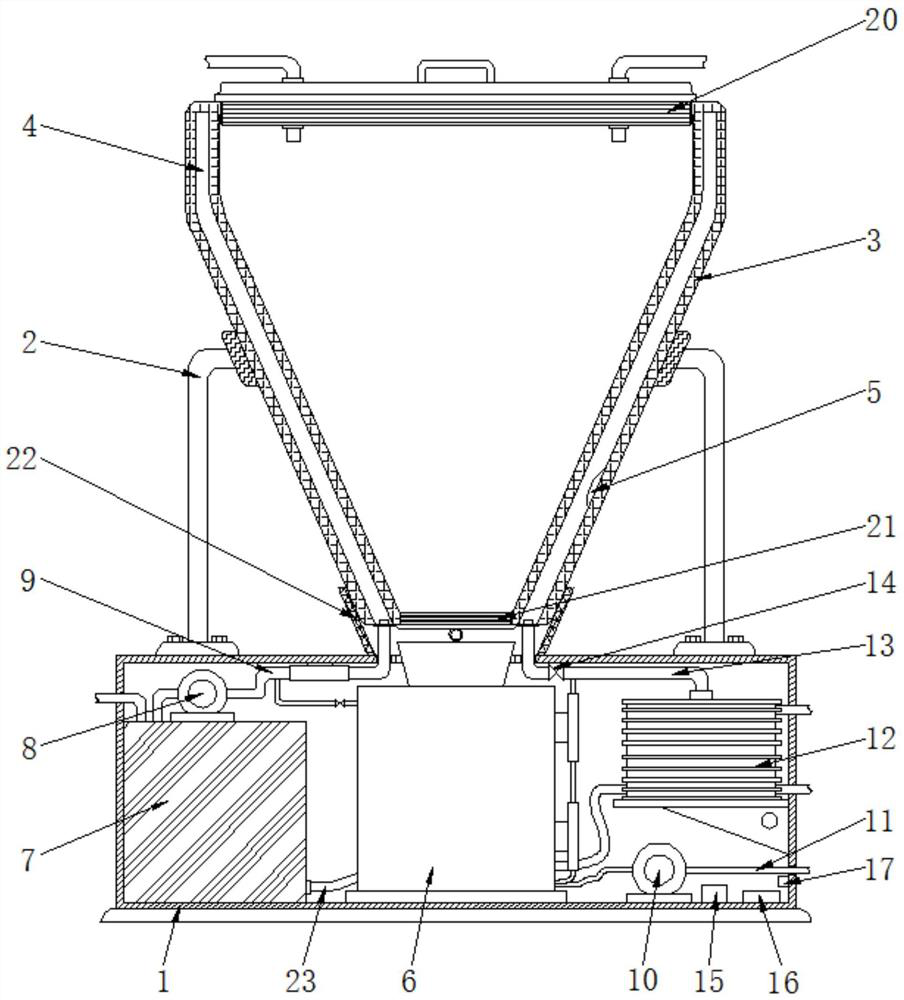

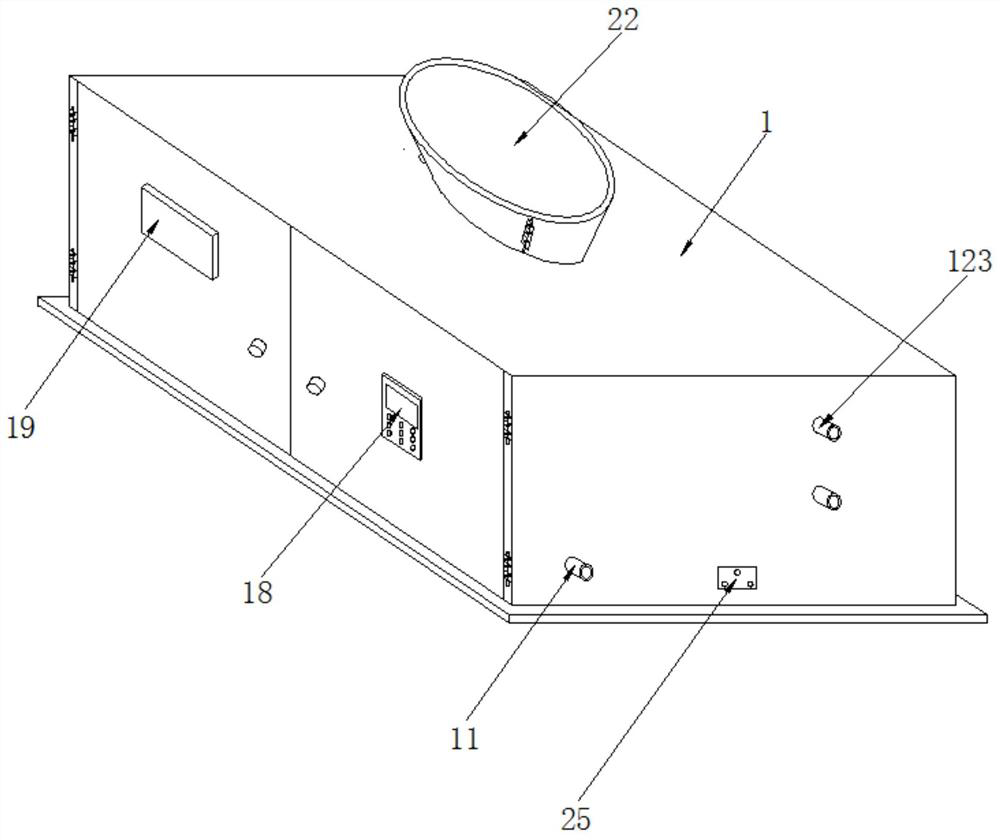

Environment-friendly waste heat recovery device of boiler pressure vessel and working method of environment-friendly waste heat recovery device

ActiveCN110763064AImprove recycling effectRealize real-time detectionHeat storage plantsHeat exchange apparatusLiquid wasteProcess engineering

The invention discloses an environment-friendly waste heat recovery device of a boiler pressure vessel and a working method of the environment-friendly waste heat recovery device. The environment-friendly waste heat recovery device comprises a machine box. A supporting frame is fixedly connected to the two sides of the top of the machine body through bolts, and a pressure vessel body is placed ina conic sleeve ring of the supporting frame. Empty grooves are formed in the pressure vessel body, and a temperature sensor is fixedly mounted on the inner wall of one empty groove. The number of outlets of the empty grooves is two. The invention relates to the technical field of boiler waste heat recovery equipment. According to the environment-friendly waste heat recovery device of the boiler pressure vessel and the working method of the environment-friendly waste heat recovery device, omni-directional waste heat recovery on the boiler pressure vessel can be achieved, the problems that wasteheat recovery is only carried out on boiler waste slag, and waste heat resources on the inner wall of the boiler pressure vessel are still wasted are solved well, the waste heat recovery effect is greatly enhanced, meanwhile, waste heat recovery is carried out on liquid waste, gas waste and solid waste, and the aim of carrying out comprehensive waste heat recovery on the boiler pressure vessel isachieved well.

Owner:合肥化机装备制造有限公司

Oil and gas dual-purpose heat accumulating type environment-friendly burner

The invention provides an oil and gas dual-purpose heat accumulating type environment-friendly burner which comprises a heat accumulator, a connecting pipe, a cooling pipe, an oil and gas dual-purpose spray gun, a burner body, a burner core brick and a burner seat brick, wherein the burner body is communicated with the heat accumulator through the connecting pipe; the cooling pipe is installed inthe middle of the burner body; the burner core brick is installed on the burner body; the burner seat brick and the burner core brick are in butt joint; the burner seat brick is communicated with theburner core brick; and the oil and gas dual-purpose spray gun penetrates through the center of the cooling pipe to be in butt joint with the burner core brick. The burner is safe and stable in use, not only can meet the requirement for using different fuels because of energy structure adjustment to be convenient for users to use flexibly but also can fully recycle the waste heat to achieve the effects of energy saving and emission reduction.

Owner:SUZHOU LONGRAY THERMAL TECH

An environment-friendly boiler pressure vessel waste heat recovery device and its working method

ActiveCN110763064BRealize waste heat recoverySolve wasteHeat storage plantsHeat exchange apparatusLiquid wasteProcess engineering

The invention discloses an environment-friendly waste heat recovery device of a boiler pressure vessel and a working method of the environment-friendly waste heat recovery device. The environment-friendly waste heat recovery device comprises a machine box. A supporting frame is fixedly connected to the two sides of the top of the machine body through bolts, and a pressure vessel body is placed ina conic sleeve ring of the supporting frame. Empty grooves are formed in the pressure vessel body, and a temperature sensor is fixedly mounted on the inner wall of one empty groove. The number of outlets of the empty grooves is two. The invention relates to the technical field of boiler waste heat recovery equipment. According to the environment-friendly waste heat recovery device of the boiler pressure vessel and the working method of the environment-friendly waste heat recovery device, omni-directional waste heat recovery on the boiler pressure vessel can be achieved, the problems that wasteheat recovery is only carried out on boiler waste slag, and waste heat resources on the inner wall of the boiler pressure vessel are still wasted are solved well, the waste heat recovery effect is greatly enhanced, meanwhile, waste heat recovery is carried out on liquid waste, gas waste and solid waste, and the aim of carrying out comprehensive waste heat recovery on the boiler pressure vessel isachieved well.

Owner:合肥化机装备制造有限公司

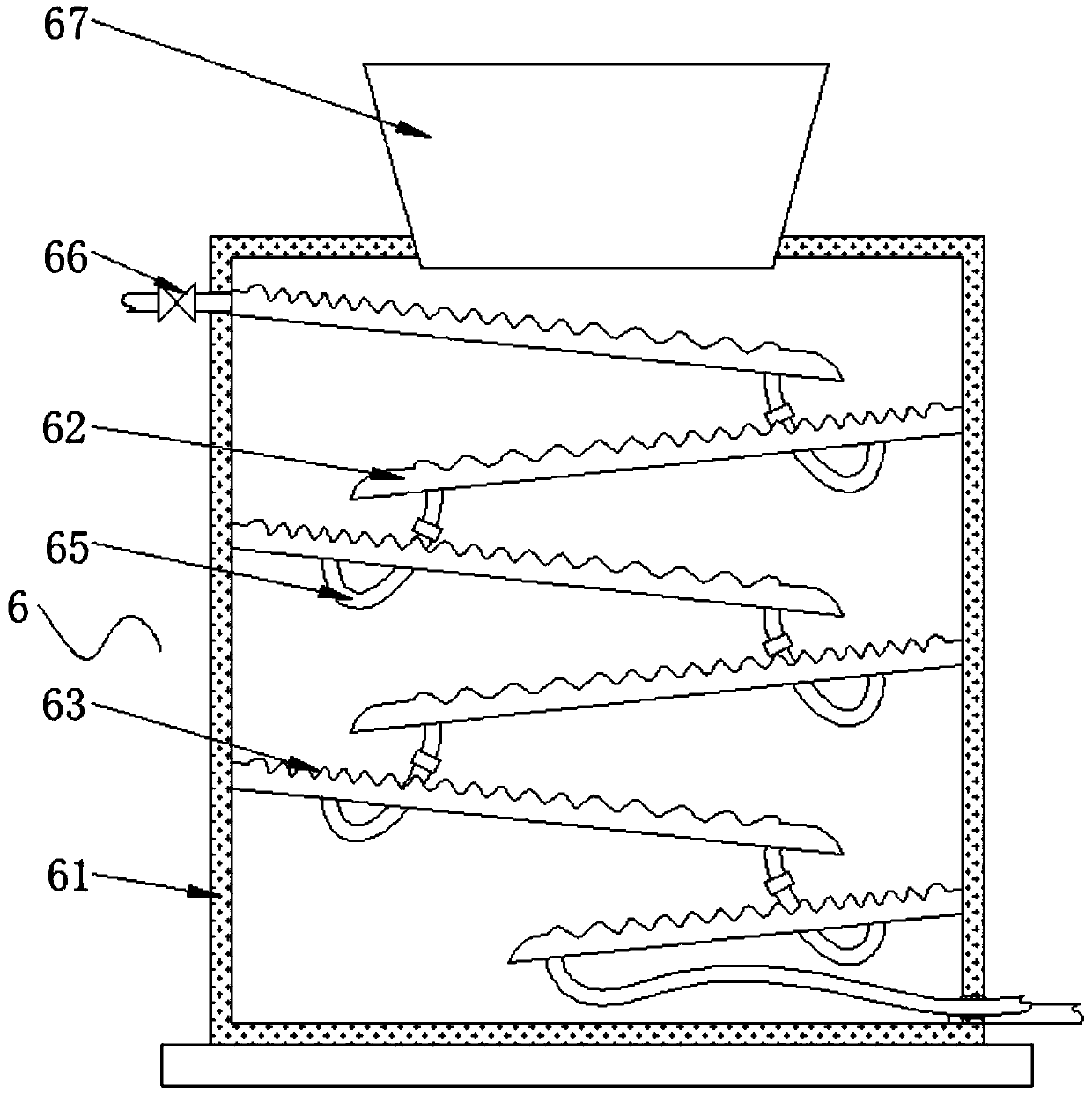

CSP heating furnace flue gas recirculation waste heat recovery system

ActiveCN114396807AReduce pollutionSlow down circulationIncreasing energy efficiencyFurnace typesThermodynamicsFlue gas

The invention relates to the technical field of waste heat recovery, in particular to a CSP heating furnace flue gas recirculation waste heat recovery system which comprises a working bin, a flue gas filtering device and a waste heat recovery device. The working bin comprises a square filtering bin and a recycling bin which is fixedly communicated with the top end of the filtering bin and is of a square structure, the smoke filtering device is assembled in the filtering bin, and the waste heat recycling device is assembled on the recycling bin; according to the system provided by the invention, flue gas filtration is additionally arranged before waste heat recovery, so that the problem that waste heat exchange recovery is influenced by adhesion and deposition of flue gas dust particles is avoided, meanwhile, incrustation cleaning can be actively carried out in real time, and the influence of an incrustation layer on the heat exchange effect is avoided or reduced.

Owner:江苏道和环保科技有限公司 +1

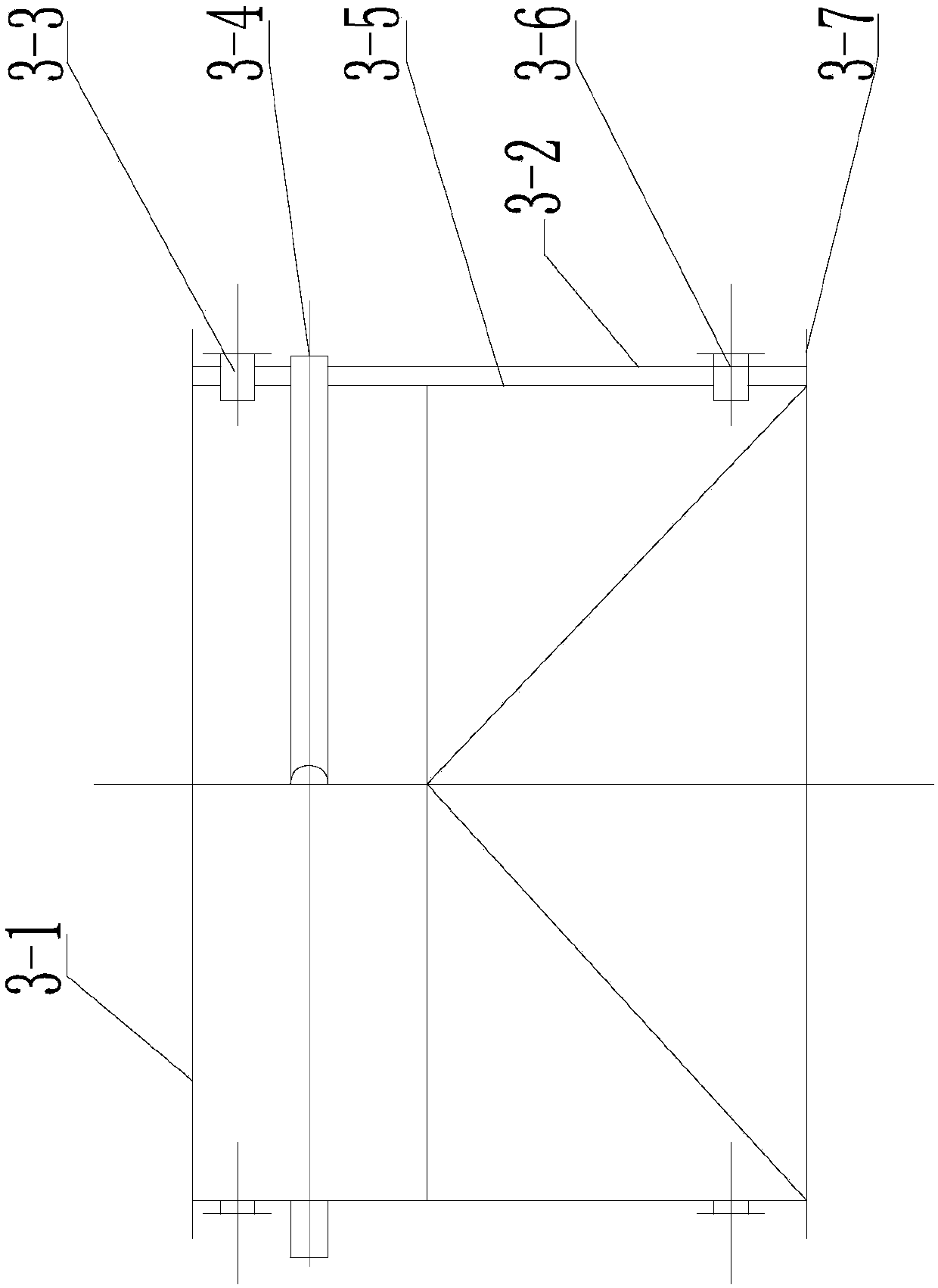

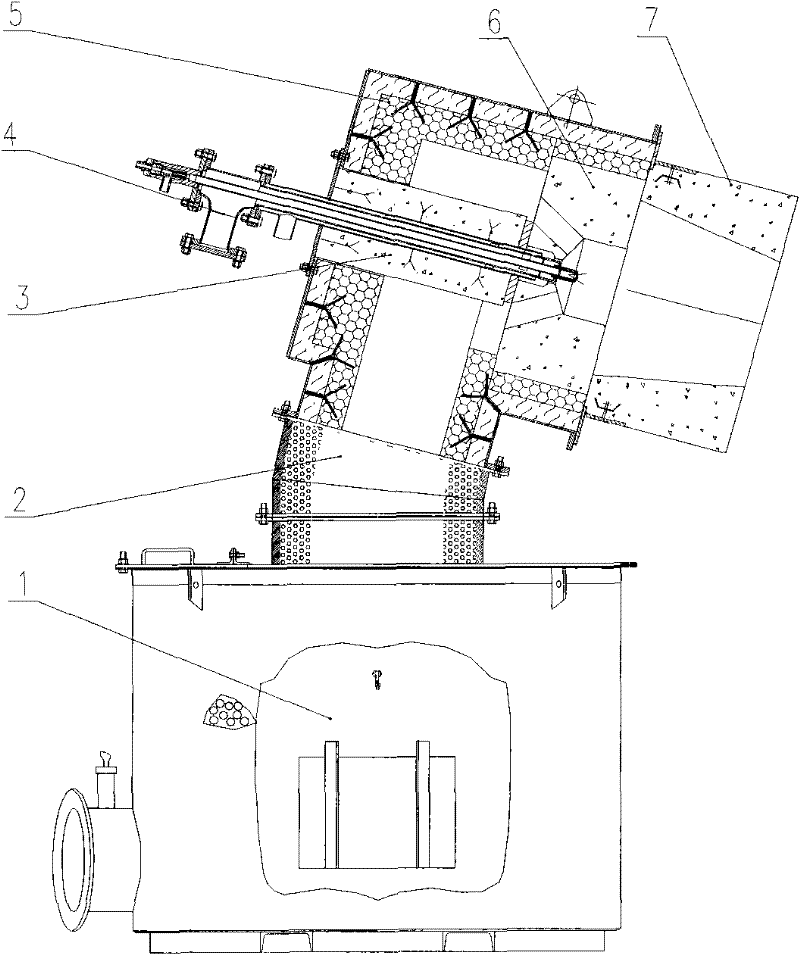

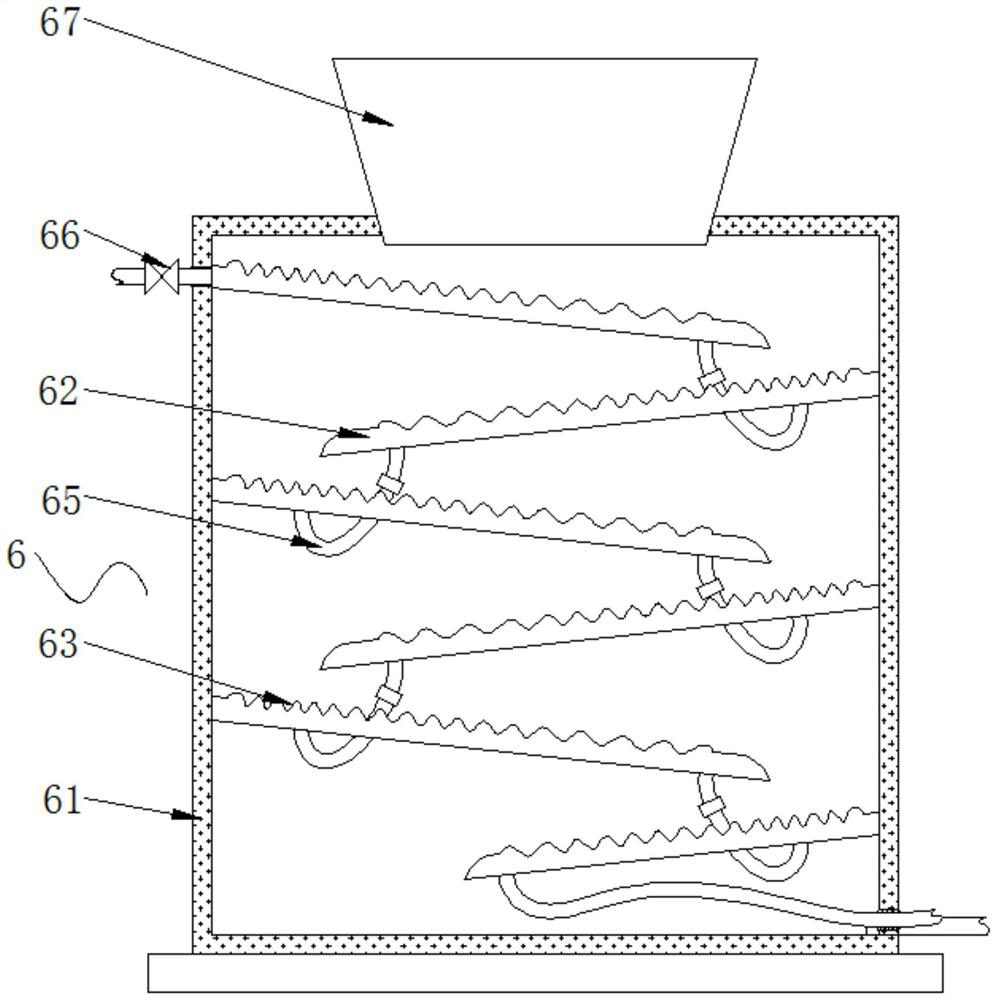

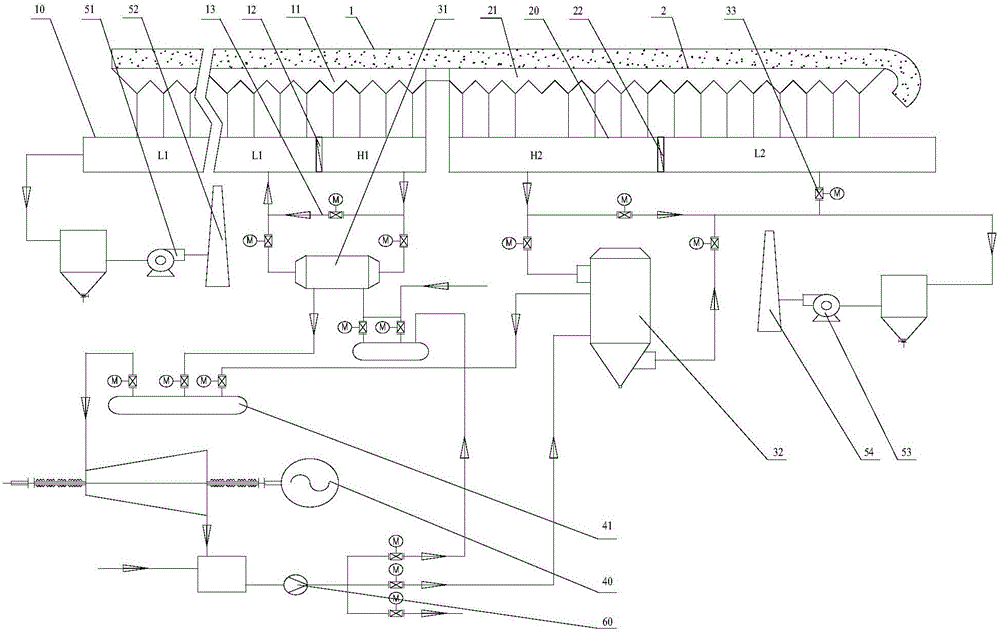

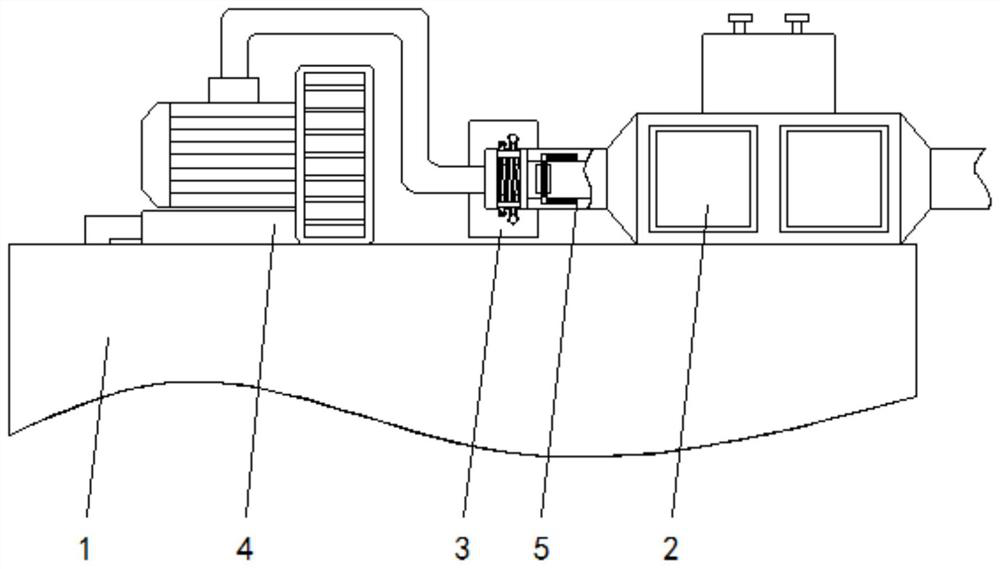

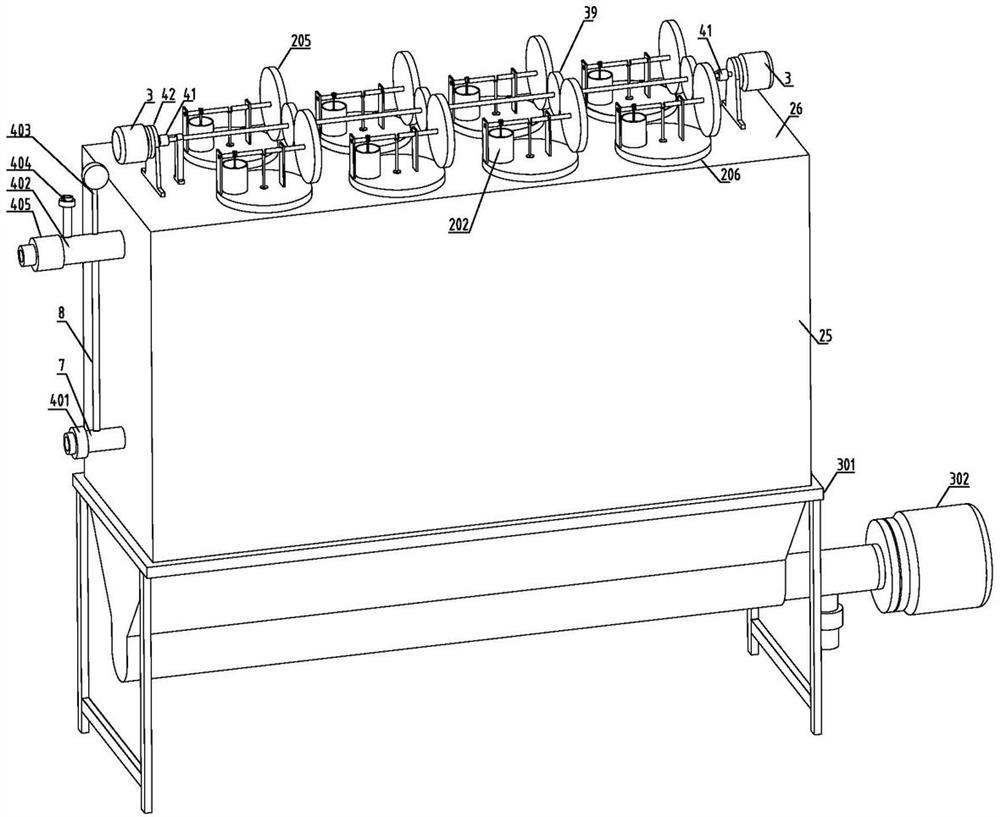

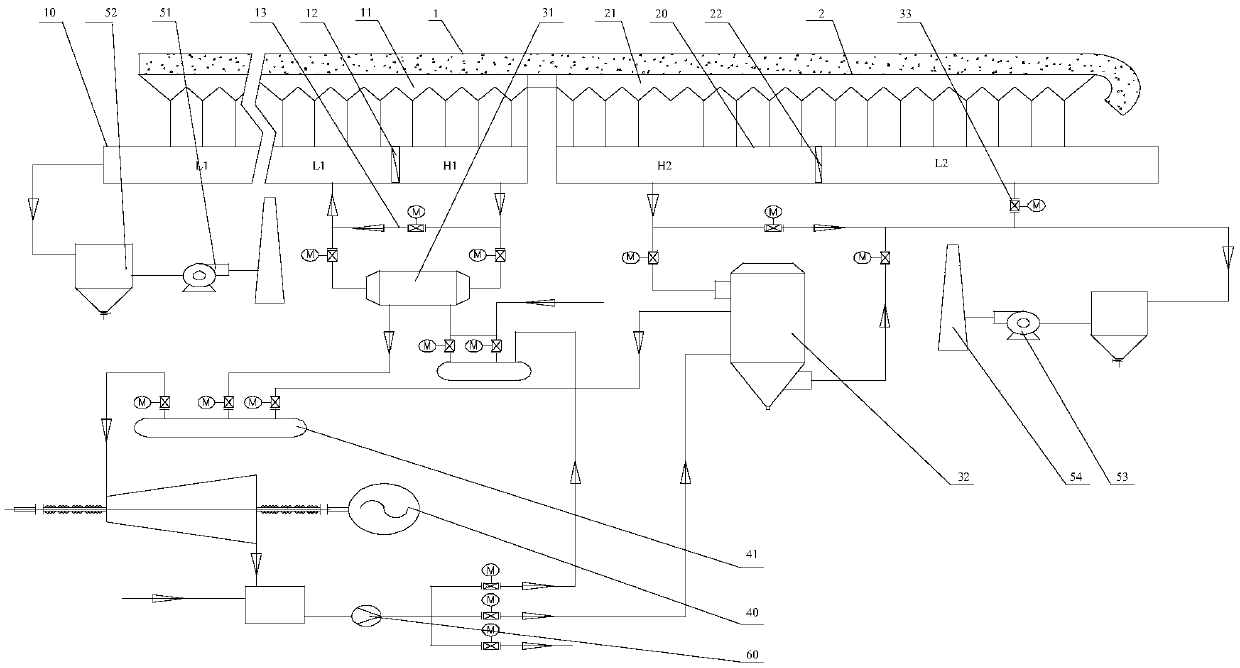

Waste heat recovery device and recovery method of stepping type flat-burning sintering machine

ActiveCN106766951AWill not affect normal workFull waste heat recoveryEnergy industryCharge treatment typeRecovery methodWaste heat recovery unit

The invention discloses a waste heat recovery device and recovery method of a stepping type sintering machine. High-temperature wind in a sintering section flue and a cooling section flue is intercepted by the waste heat recovery device to conduct heat exchanging, so that full waste heat recovery is realized, heat-exchanged low-temperature wind is sent back into the sintering section flue and the cooling section flue, and the normal working of the stepping type flat-burning sintering machine is not affected.

Owner:北京天朗致达节能环保股份有限公司

Activated carbon processing equipment

PendingCN114408925ARealize heatingReduce heat lossCarbon compoundsActivated carbonCombustion chamber

The invention discloses activated carbon processing equipment which comprises an activation furnace, the activation furnace comprises a furnace body, a combustion chamber and an activation channel are formed in the furnace body, and the activation channel is communicated with the combustion chamber at the discharge end of the activation channel; a negative pressure suction device communicated with the combustion chamber is arranged at the feeding end of the furnace body, an air inlet communicated with the combustion chamber is formed in the furnace body, and the negative pressure suction device is used for sucking air and activated tail gas generated in the activation channels into the combustion chamber to be combusted and release heat so as to supply heat to the activation channels. According to the invention, the negative pressure suction device communicated with the combustion chamber is arranged at the feeding end of the activation furnace, so that the activated tail gas and high-temperature flue gas generated by combustion of the activated tail gas cannot escape from the activation furnace under the negative pressure suction, and can be directly utilized in the activation furnace without being led out for purification, and the heat loss is greatly reduced.

Owner:安徽久泰新材料科技有限公司 +1

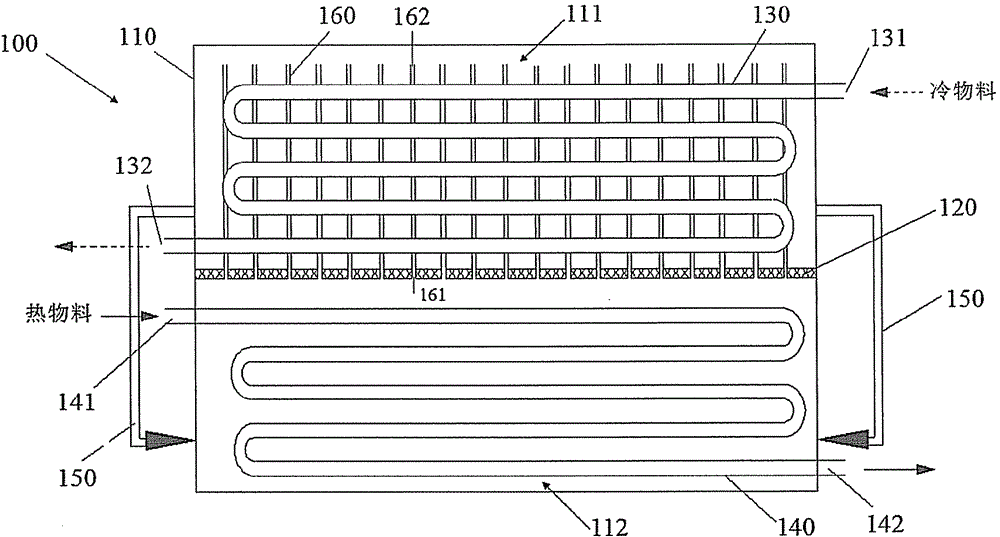

Heat Exchanger

ActiveCN103196316BReduce resistanceReduce settlementIndirect heat exchangersEngineeringCommunication device

Owner:ENN SCI & TECH DEV

Complete equipment of system for converting conduction oil waste heat into steam and use method of equipment

PendingCN113280318ASo as not to damageExtend heat exchange timeBoiler controlIncreasing energy efficiencyTemperature controlWater treatment system

The invention relates to the technical field of waste heat recycling, in particular to complete equipment of a system for converting conduction oil waste heat into steam and a use method of the equipment. The complete equipment of a system for converting conduction oil waste heat into steam comprises a heat exchange system, a water treatment system, a heat conduction oil conveying system and a steam treatment system, wherein the heat exchange system comprises a steam generator and a water heater communicating with the steam generator, a heat conduction oil conveying pipe is arranged in the steam generator, the tail end of the heat conduction oil conveying pipe communicates with an inner cavity of the water heater, a water body conveying pipe is arranged in the water heater, and the tail end of the water body conveying pipe communicates with an inner cavity of the steam generator; the heat conduction oil conveying system comprises a heat conduction oil inlet, a three-way temperature control valve and a heat conduction oil outlet, the heat conduction oil inlet communicates with the three-way temperature control valve, the three-way temperature control valve communicates with the steam generator, and the heat conduction oil outlet communicates with the water heater; and the water treatment system communicates with the water heater, and the steam treatment system communicates with the steam generator. With the equipment, heat of high-temperature heat conduction oil is fully recycled, and the waste heat is reasonably utilized.

Owner:山东水龙王科技有限公司

Boiler flue gas waste heat recycling system based on heat exchanging absorption tower and method

InactiveCN111397403ARaise the water temperatureReduce low temperature corrosionCombustion processIndirect carbon-dioxide mitigationFlue gasProcess engineering

The invention discloses a boiler flue gas waste heat recycling system based on a heat exchanging absorption tower and a method, and belongs to the technical field of flue gas waste heat recycling anddisposal. According to the system, a heat exchanging coil pipe is arranged inside the heat exchanging absorption tower; a flue gas outlet of a boiler communicates with a flue gas inlet of an electrostatic dust remover; a flue gas outlet of the electrostatic dust remover communicates with a flue gas inlet of an economizer; an flue gas outlet of the economizer communicates with a flue gas inlet of the heat exchanging absorption tower; an flue gas outlet of the heat exchanging absorption tower communicates with a flue gas inlet of a dehydrator; a flue gas outlet of the dehydrator communicates with a diverter; the diverter communicates with a denitration device and an air mixer respectively; the air mixer communicates with a draught fan and is connected with an air inlet at the bottom of the boiler; and the denitration device communicates with a chimney. Via the arrangement of the heat exchanging absorption tower, the functions of desulfuration, denitration and heat exchange are integrated, flue gas is in direct contact with ammonia, and water inflow in the heat exchanging coil pipe from the boiler is heated, so the heat transfer coefficient is increased, heat transfer efficiency is improved, the temperature of water inflow in the economizer is increased, low-temperature corrosion of the economizer is lessened, and a desulfuration device is omitted.

Owner:SOUTH CHINA UNIV OF TECH +1

Shell-and-tube heat exchanger for collecting residual heat of boiler

InactiveCN106765249AAvoid accumulationHigh recycling efficiencyCombustion technology mitigationFlush cleaningPlate heat exchangerShell and tube heat exchanger

The invention relates to a shell-and-tube heat exchanger for collecting residual heat of a boiler. A high-pressure water tank is arranged at the top of the heat exchanger; a plurality of water spraying holes are formed in a connecting part of the high-pressure water tank and the heat exchanger; an ultrasonic atomizer is arranged on each of a left side wall and a right side wall of the heat exchanger; a plurality of atomization holes are formed in connecting parts of the ultrasonic atomizers and the heat exchanger. The high-pressure water tank is arranged at the top of the heat exchanger, and water in the high-pressure water tank is used for flushing smoke dust on tube walls of heat exchange tubes from the water spraying holes; meanwhile, the ultrasonic atomizers are arranged on the side walls of the heat exchanger, so that water mist sprayed out from the ultrasonic atomizers is sufficiently combined with flue gas, and the smoke dust is prevented from being accumulated on the walls of the heat exchange tubes; the relatively high heat exchange efficiency can be continually kept, and the recycling benefits of a residual heat system are improved.

Owner:JIANGSU HUAYUE SPECIAL EQUIP

A device for recovering waste heat from printing and dyeing equipment

ActiveCN111637777BShorten speedReduce flow rateRecuperative heat exchangersTextile treatment machine partsThermodynamicsProcess engineering

The invention relates to the technical field of printing and dyeing equipment, and discloses a device for recovering waste heat of printing and dyeing equipment, including the printing and dyeing equipment. The device for recovering waste heat from printing and dyeing equipment uses a fan to blow the hot air inside the printing and dyeing equipment into the inside of the fixed block. The air enters in a spiral, which effectively reduces the speed of hot air entering, and the hot air impacts the rotating fan blades. At this time, the rotating fan blades, movable blocks and buffer springs work together to further buffer the effect. The device passes through a series of The unique mechanical structure reduces the flow rate of hot air entering the waste heat recovery device, so that the hot air stays in the waste heat recovery device for a long time, which can fully recover waste heat and make waste heat recovery more efficient. The rotating block fits closely with the guide groove.

Owner:江苏新世嘉家纺高新科技股份有限公司

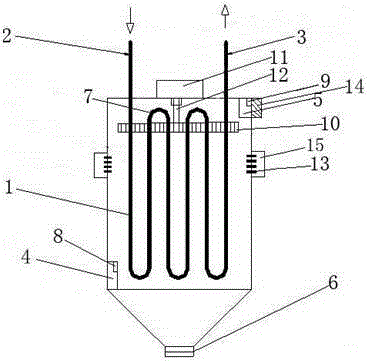

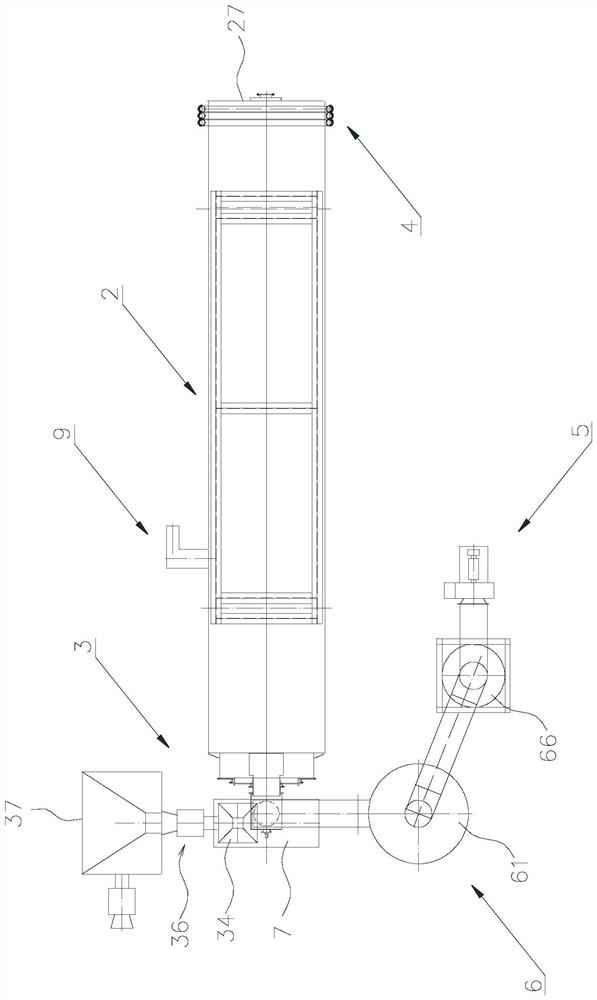

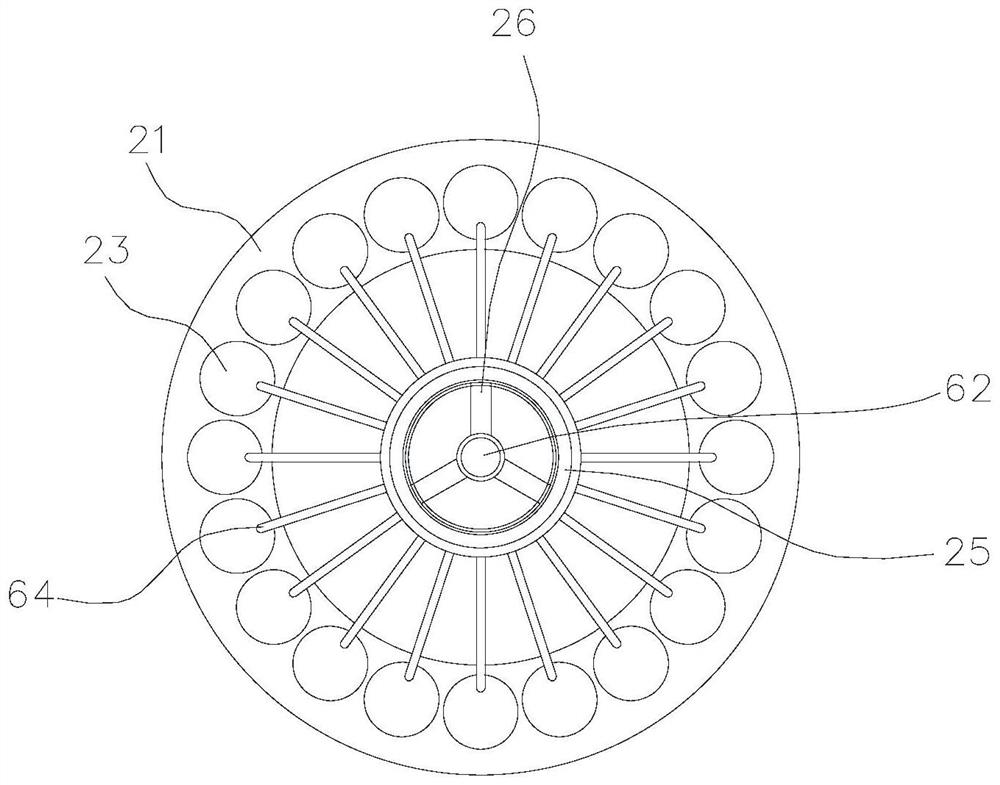

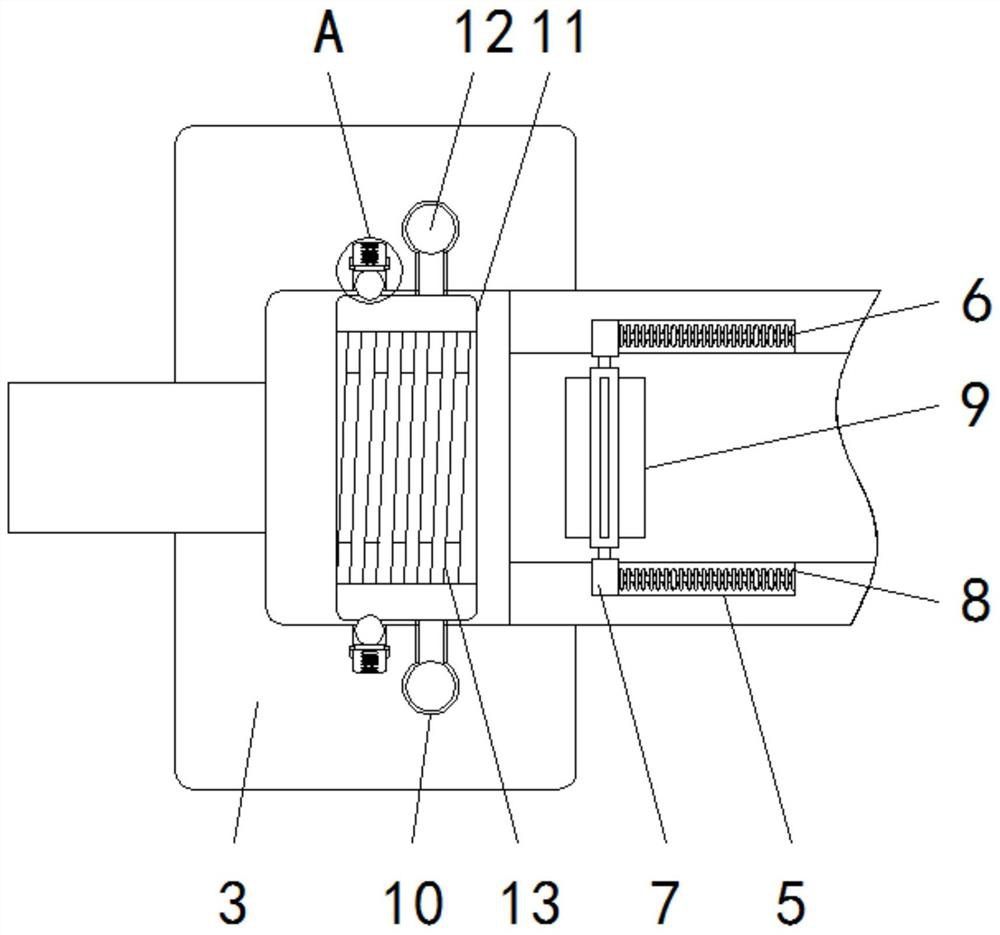

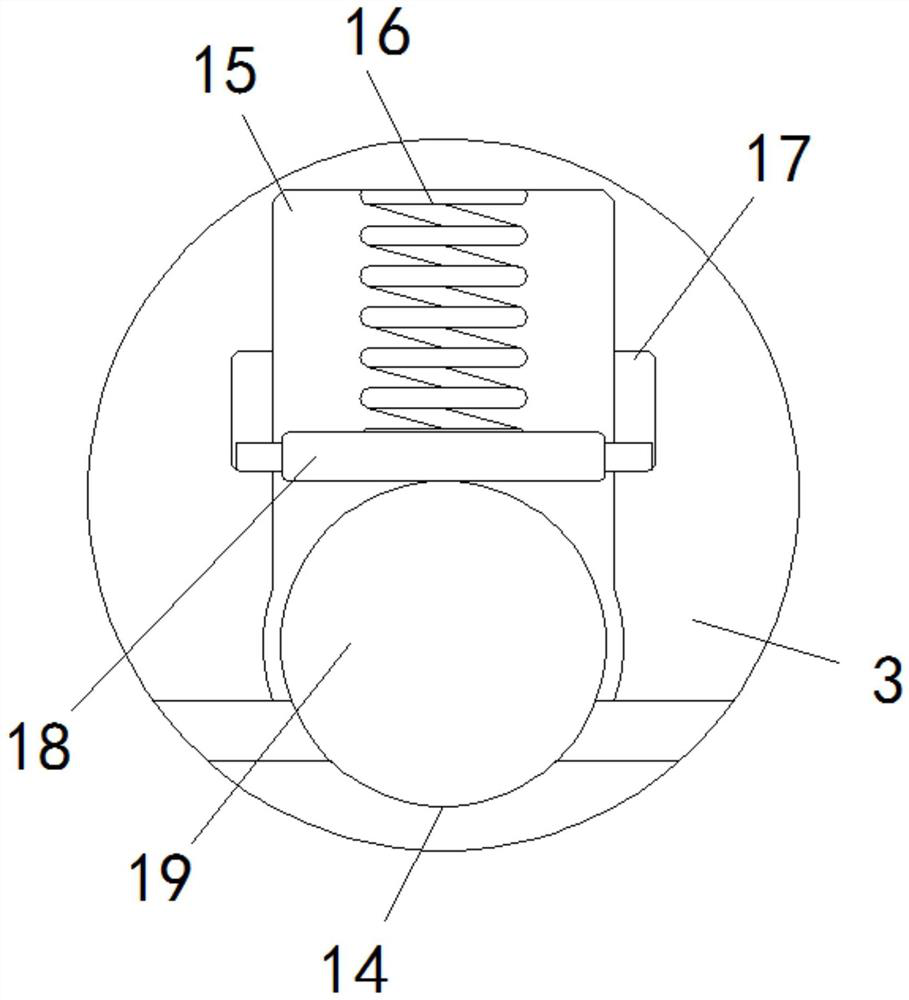

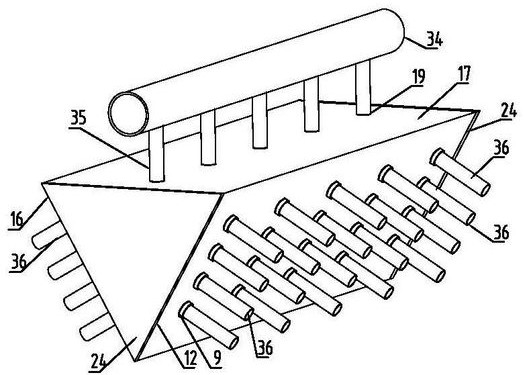

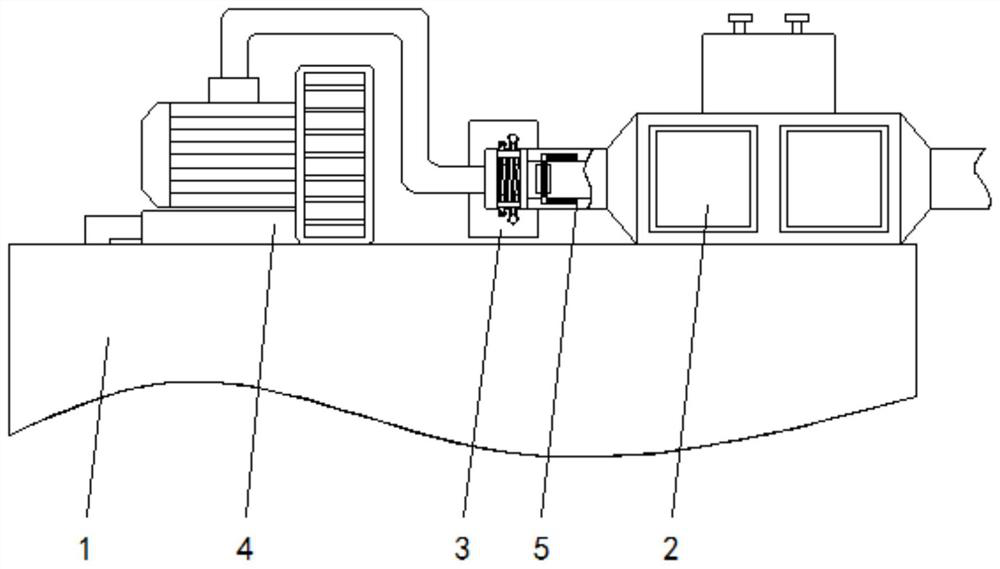

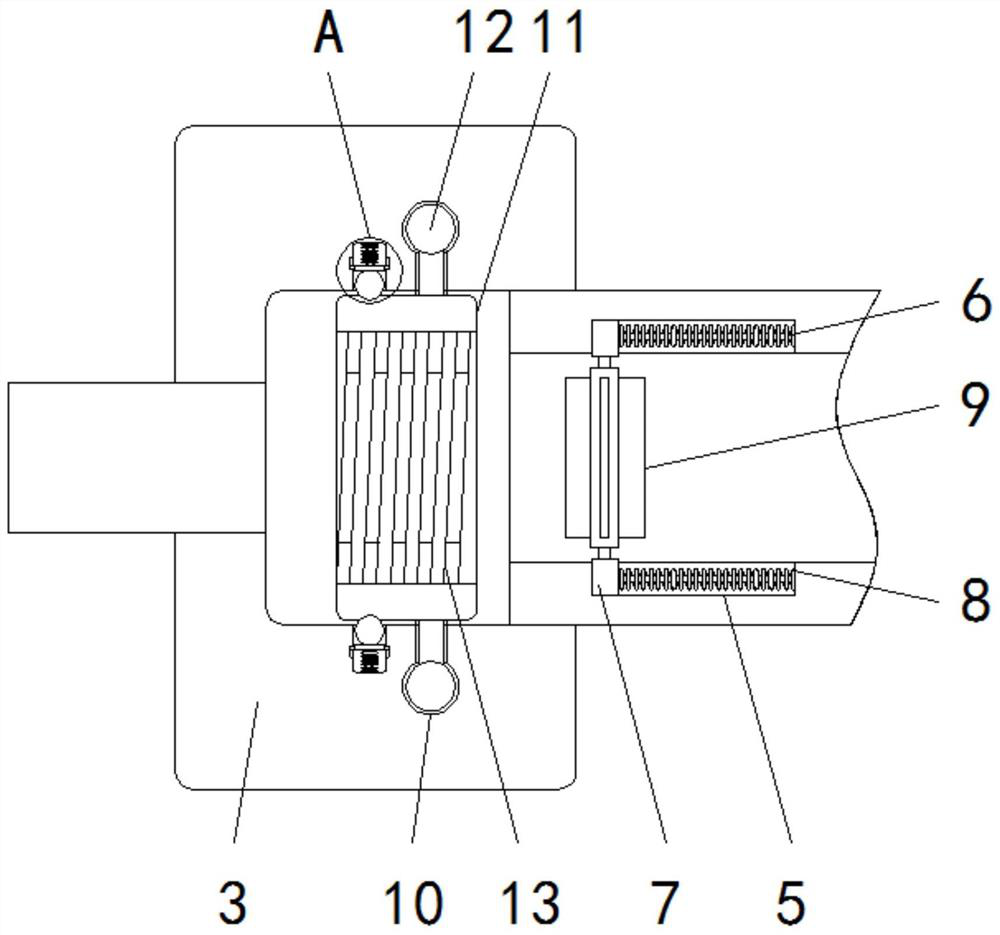

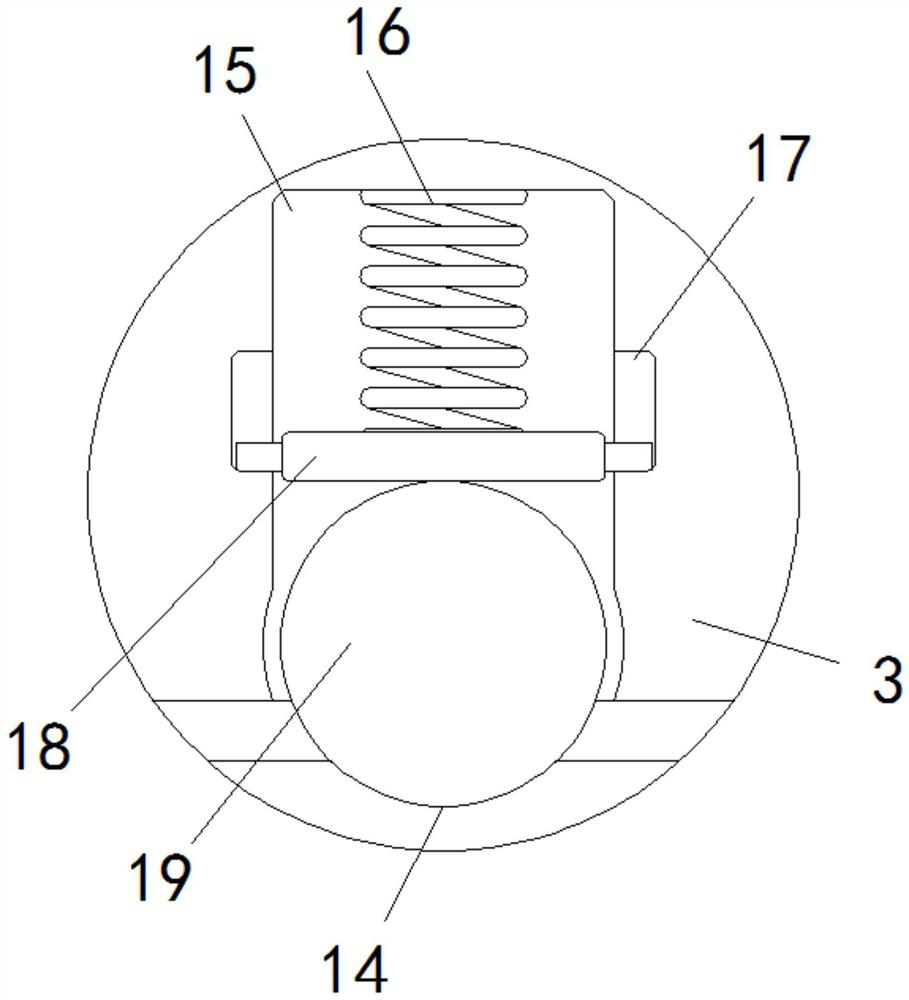

Hot flue gas purification and waste heat power generation integrated device

InactiveCN113654370AAvoid cloggingFull waste heat recoveryIncreasing energy efficiencyIce removalWater vaporFlue gas

The invention provides a hot flue gas purification and waste heat power generation integrated device. The hot flue gas purification and waste heat power generation integrated device comprises a steam generator for flue gas cooling, a transmission component, a Stirling engine and a power generator. The device has the effects that superheated steam in flue gas can be condensed to recycle sensible heat and latent heat in the flue gas, the effect that airflow in each heat exchange branch pipe is uniform is achieved through parts and the structure, and the device has the characteristics of being sufficient in waste heat recycling and high in heat exchange efficiency; and according to the device, the phenomenon that the heat exchange pipeline is blocked by fog drops generated by condensation of dust, low-boiling-point organic volatile matters, water vapor and the like in the heat exchange branch pipes can be reduced or avoided, meanwhile, the effect of removing some dust and condensate to purify flue gas is achieved, and the phenomena of cracking and steam leakage caused by thermal stress of connection points of different parts are reduced or avoided. According to a transmission component, power of the multiple Stirling engines is collected and then supplied to one generator, and the transmission component has the characteristics of being compact in equipment, small in occupied space, long in service life and good in safety.

Owner:PULIN TAIYANG ZHENGZHOU ENERGY POWER

Gas water heater and waste heat recovery method

ActiveCN106369825BFull waste heat recoveryHigh thermal efficiencyFluid heatersIndirect heat exchangersRecovery methodCombustion chamber

The invention relates to a gas water heater and a waste heat recycle method. The gas water heater comprises a combustion chamber, a smoke emission pipe, a heat exchange passage, a main heat exchanger and a waste heat recycle device, wherein the heat exchange passage communicates with the combustion chamber and the smoke emission pipe; the waste heat recycle device comprises a heat pipe module; one end of the heat pipe module is located in the heat exchange passage, and the other end of the heat pipe module is located at the water inlet end of the water heater; the waste heat recycle device further comprises a heat absorption module and a heat emission module; the heat absorption module is arranged in the heat exchange passage; the heat emission module is arranged on the outer part of the heat exchange passage; and the heat pipe module is connected with the heat absorption module and the heat emission module. According to the gas water heater and the waste heat recycle method, waste heat of waste gas emitted by the gas water heater is transmitted to preheat inlet water of the gas water heater by utilizing the heat pipe. By adopting the gas water heater and the waste heat recycle method, the waste heat of high-temperature smoke of the gas water heater can be fully recycled; the heat efficiency of the gas water heater is improved; meanwhile, the gas water heater is energy-saving and environment-friendly; the structure is simple; and cost is low.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

Shell-and-tube heat exchanger of heat recovery boiler

InactiveCN106765258AAvoid accumulationHigh recycling efficiencyCombustion technology mitigationSolid removalRecuperatorEngineering

The invention relates to a shell-and-tube heat exchanger of a heat recovery boiler. A heat exchange nest of tubes is vertically arranged inside the heat exchanger. A water inlet and a water outlet are formed in the two ends of the heat exchange nest of tubes correspondingly. Both the water inlet and the water outlet are formed in the top of the heat exchanger. An air inlet is formed in the lower end of the left side of the heat exchanger. An air outlet is formed in the upper end of the right side of the heat exchanger, and a containing opening is formed in the bottom of the heat exchanger. A high-pressure water tank is arranged at the top of the heat exchanger. A plurality of water spraying holes are formed in the connecting position of the high-pressure water tank and the heat exchanger. Due to arrangement of the high-pressure water tank at the top of the heat exchanger, water in the high-pressure water tank can wash soot on the tube walls of the heat exchange nest of tubes through the water spraying holes, high heat exchange efficiency can be kept continuously, waste heat recovery is fully conducted, and the recovery benefits of a waste heat system are increased.

Owner:JIANGSU HUAYUE SPECIAL EQUIP

A high-temperature flue gas waste heat recovery and deep purification system

ActiveCN106989607BExtend the distribution pathExtended stayIncreasing energy efficiencySteam engine plantsOrganic Rankine cycleFlue gas

Owner:CENT SOUTH UNIV

Waste heat recovery device and recovery method of a stepping flat sintering sintering machine

ActiveCN106766951BWill not affect normal workFull waste heat recoveryEnergy industryCharge treatment typeThermodynamicsProcess engineering

Owner:北京天朗致达节能环保股份有限公司

Device for recovering waste heat of printing and dyeing equipment

ActiveCN111637777AShorten speedReduce flow rateRecuperative heat exchangersTextile treatment machine partsThermodynamicsProcess engineering

The invention relates to the technical field of printing and dyeing equipment, and discloses a device for recovering waste heat of the printing and dyeing equipment. The device comprises the printingand dyeing equipment. According to the device for recovering waste heat of the printing and dyeing equipment, hot air inside the printing and dyeing equipment is blown into a fixed block through a fan, and then pushes a helical sheet to drive a rotating sleeve to rotate, and the rotating sleeve and the helical sheet helically introduces the hot air in turn, so that the entrance speed of the hot air is reduced effectively. In addition, the hot air impacts a rotary fan blade, and then the rotary fan blade, a movable block and a buffer spring co-act to achieve a further buffering effect. According to the device, the flow rate of the hot air entering a waste heat recovery device is reduced through a series of mechanical structures, so that the hot air remains inside the waste heat recovery device for a long time; the waste heat can be fully recovered; and higher waste heat recovery efficiency is achieved. In addition, a rotary block is in close fit with a guide groove through a pressure spring and a top plate.

Owner:江苏新世嘉家纺高新科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com