Converter dry dedusting and waste heat recycling device and method

A converter dry dust removal and waste heat recovery device technology, which is applied to lighting and heating equipment, furnaces, waste heat treatment, etc., can solve problems such as many operating problems, explosions, troubles, etc., and achieve the effect of preventing explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

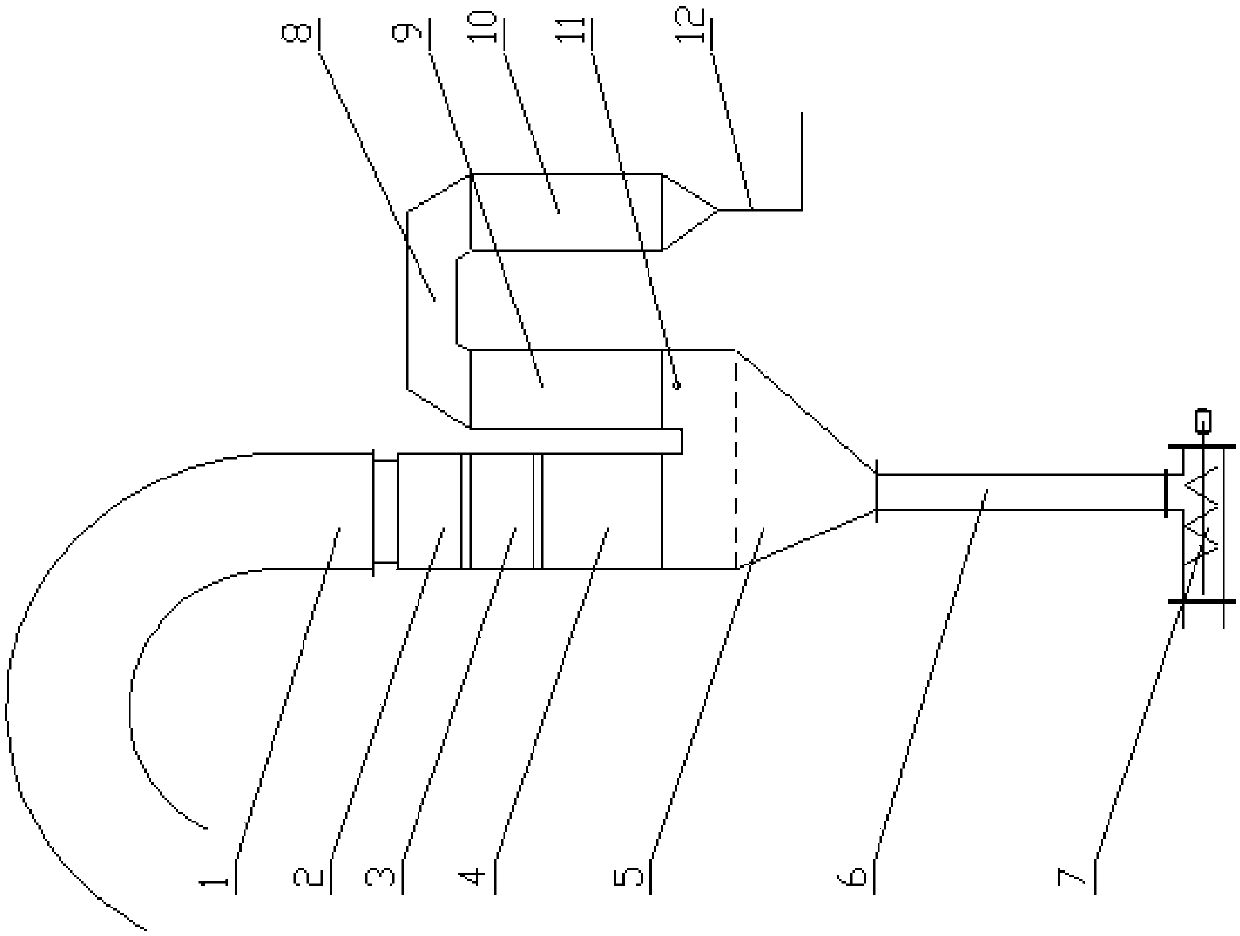

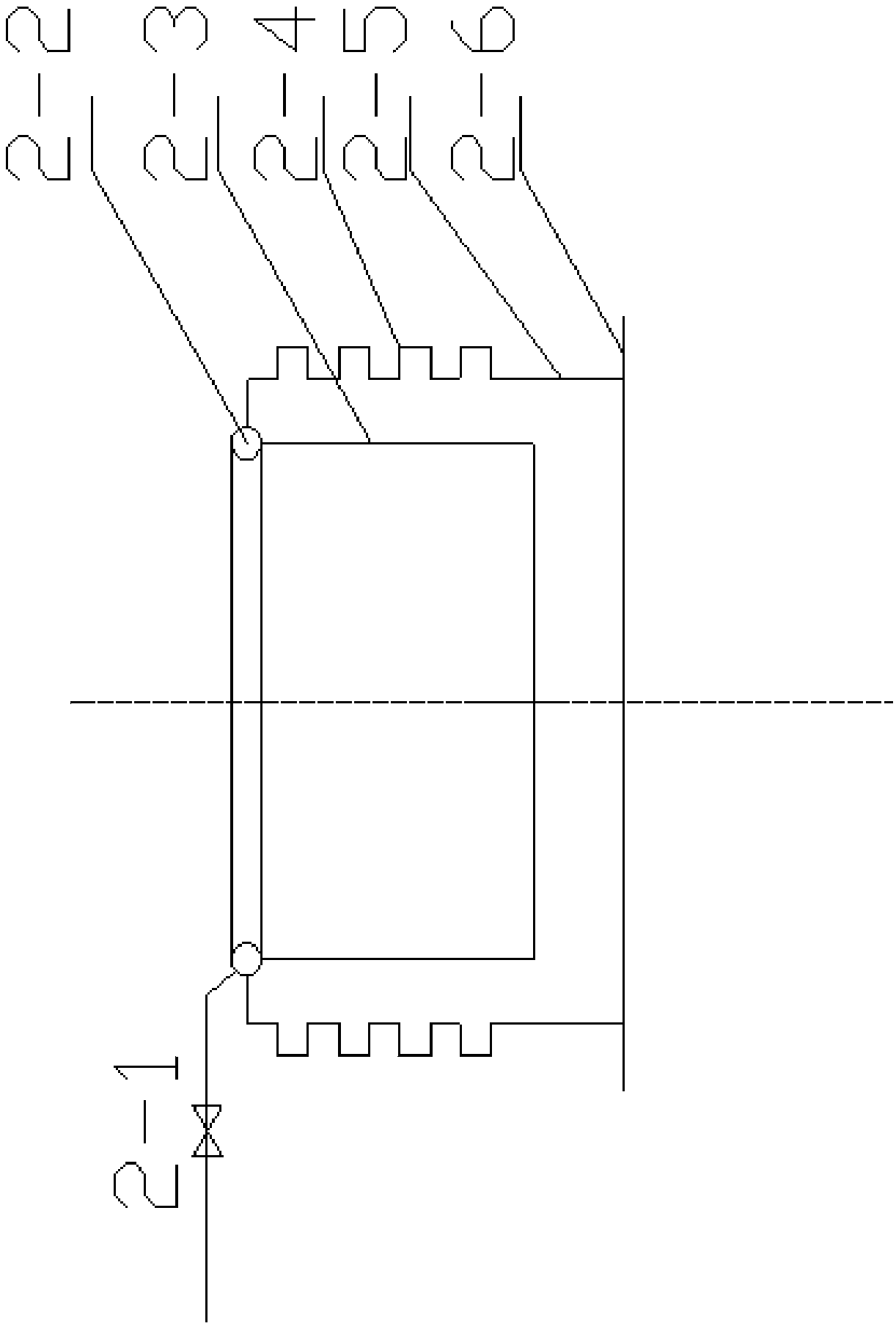

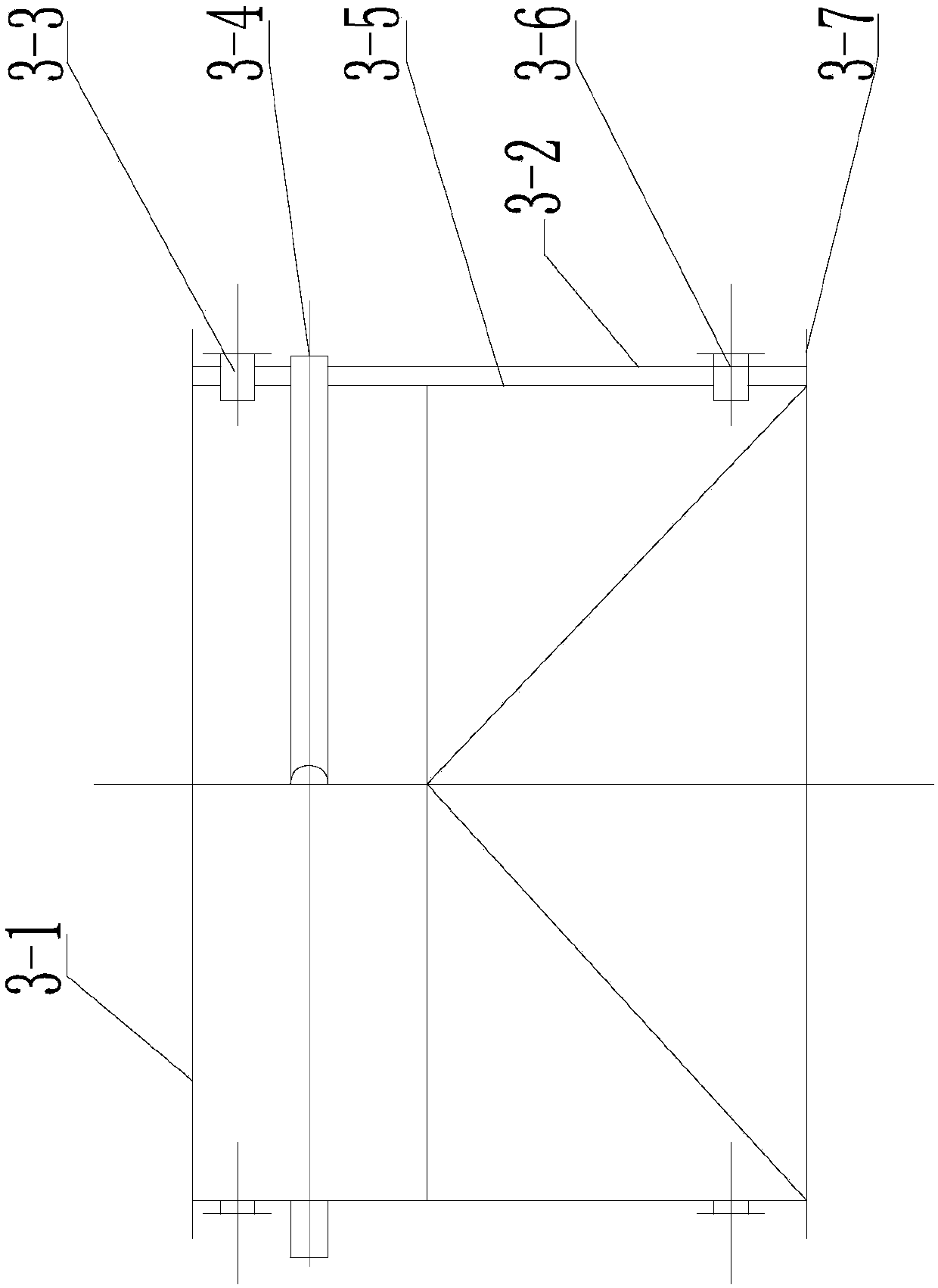

[0050] This embodiment discloses a converter dry dust removal and waste heat recovery device, such as figure 1 As shown, it includes steel flexible joint 2 installed at the outlet of converter vaporization cooling flue 1, flue gas component concentration intervention section part 3, high temperature flue gas cooling section part 4, gravity dust removal part 5, bag filter 9, low temperature flue gas Cooling section part 10 and mixer 16. Among them, the steel flexible joint 2 at the outlet of the vaporization cooling flue 1 is connected to the flue gas component concentration intervention part 3 and the high-temperature flue gas cooling section part 4 in turn, and then connected to the inlet of the gravity dust removal part, and the outlet of the gravity dust removal part is connected to the bag filter 9 The inlet and the outlet of the bag filter 9 are connected to the inlet of the low-temperature flue gas cooling section 10 through the pipeline 8, and the outlet of the low-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com