Oil and gas dual-purpose heat accumulating type environment-friendly burner

A regenerative, dual-purpose technology, applied in the field of metallurgical equipment, can solve the problems of interchangeability, unfavorable oil and gas, and time-consuming, and achieve the effects of convenient and flexible use, safe and stable use, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

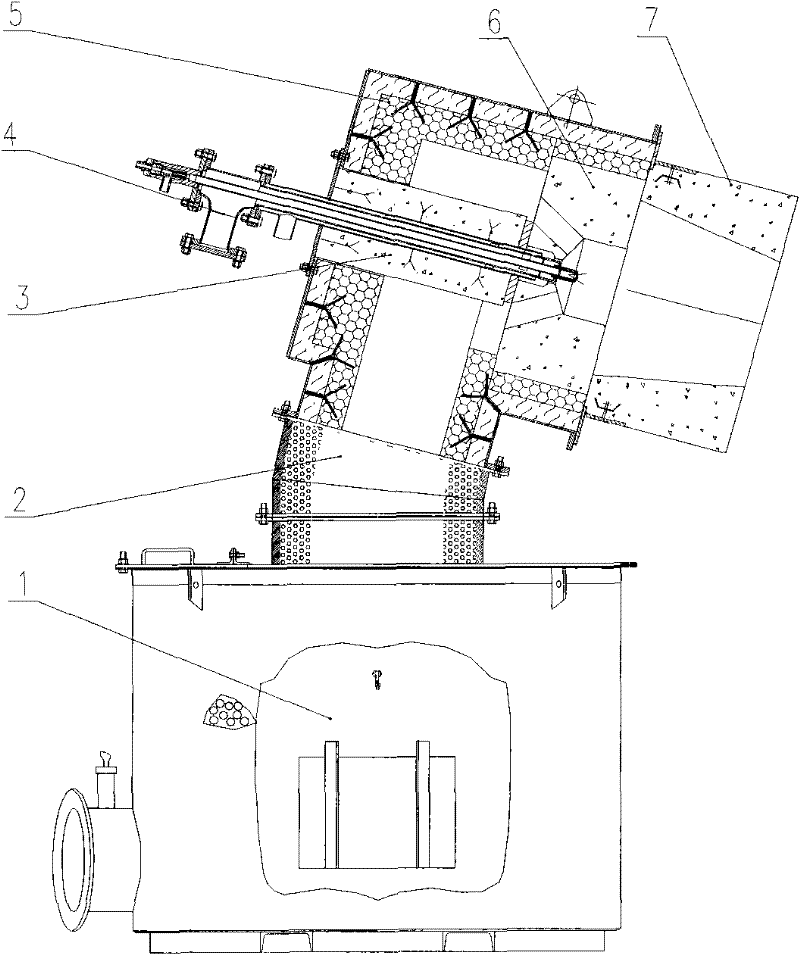

[0023] Such as figure 1 As shown, the oil-gas dual-purpose regenerative environmental protection burner includes heat storage body 1, connecting pipe 2, cooling pipe 3, oil-gas dual-purpose spray gun 4, burner body 5, burner core brick 6 and burner seat brick 7, The burner body 5 communicates with the heat storage body 1 through the connecting pipe 2, the cooling pipe 3 is installed in the middle of the burner body 5, and the burner core brick 6 is installed on the burner body 5, and the burner core brick 6 and the burner seat brick 7 butt joint installation, the burner brick 7 communicates with the burner core brick 6, and the oil and gas dual-purpose spray gun 4 passes through the center of the cooling pipe 3 and connects with the burner core brick 6. Both the burner body 5 and the connecting pipe 2 have flue gas passages, and the oil-air dual-purpose spray gun 4 passes through the center of the cooling pipe 3 to provide fuel for the combustion of the burner.

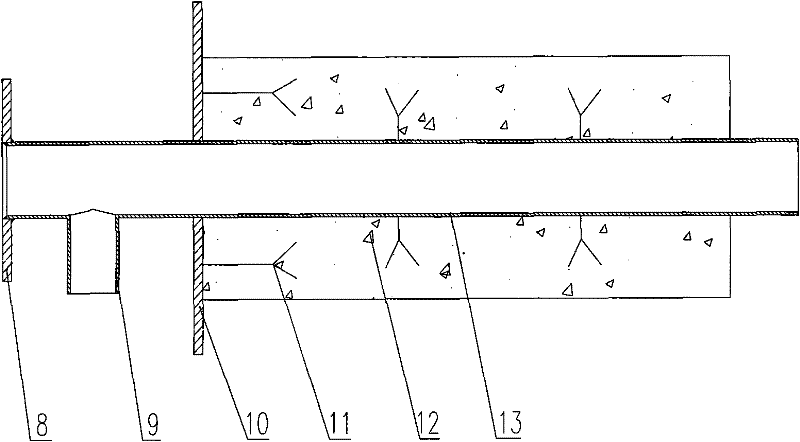

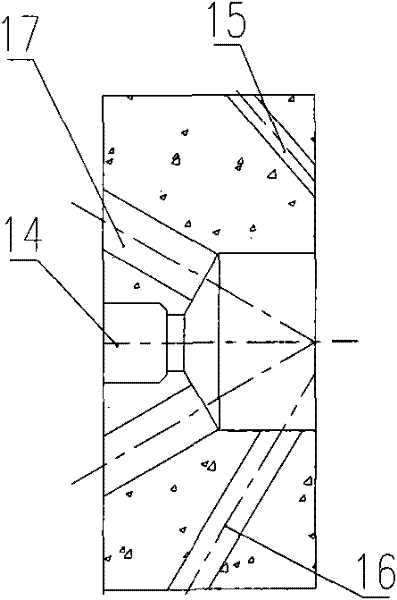

[0024] The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com