High-low pressure double-working-medium ORC power generation system with regenerative cycle

A power generation system, high and low voltage technology, applied in the field of ORC power generation system, can solve the problems of energy saving and environmental protection performance to be improved, and achieve the effect of improving waste heat recovery method, reducing heat load and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The preferred embodiment of the high-low pressure duplex ORC power generation system with heat recovery cycle of the present invention is:

[0017] Including heat source system, cold source system, high-voltage cycle power generation system, low-voltage cycle power generation system;

[0018] The high-pressure cycle power generation system includes a high-pressure evaporator and a liquid separator connected to each other. The gas-phase outlet of the liquid separator enters the expander, and the liquid-phase outlet flows into the liquid collector; the exhaust gas outlet of the expander The working fluid enters the liquid collector after being directly condensed by the condenser, and the working medium at the outlet of the extraction steam enters the liquid collector through the extraction steam regenerator and the exhaust steam regenerator; After the regenerator and extraction steam regenerator are preheated, they return to the high-pressure evaporator through the booste...

specific Embodiment

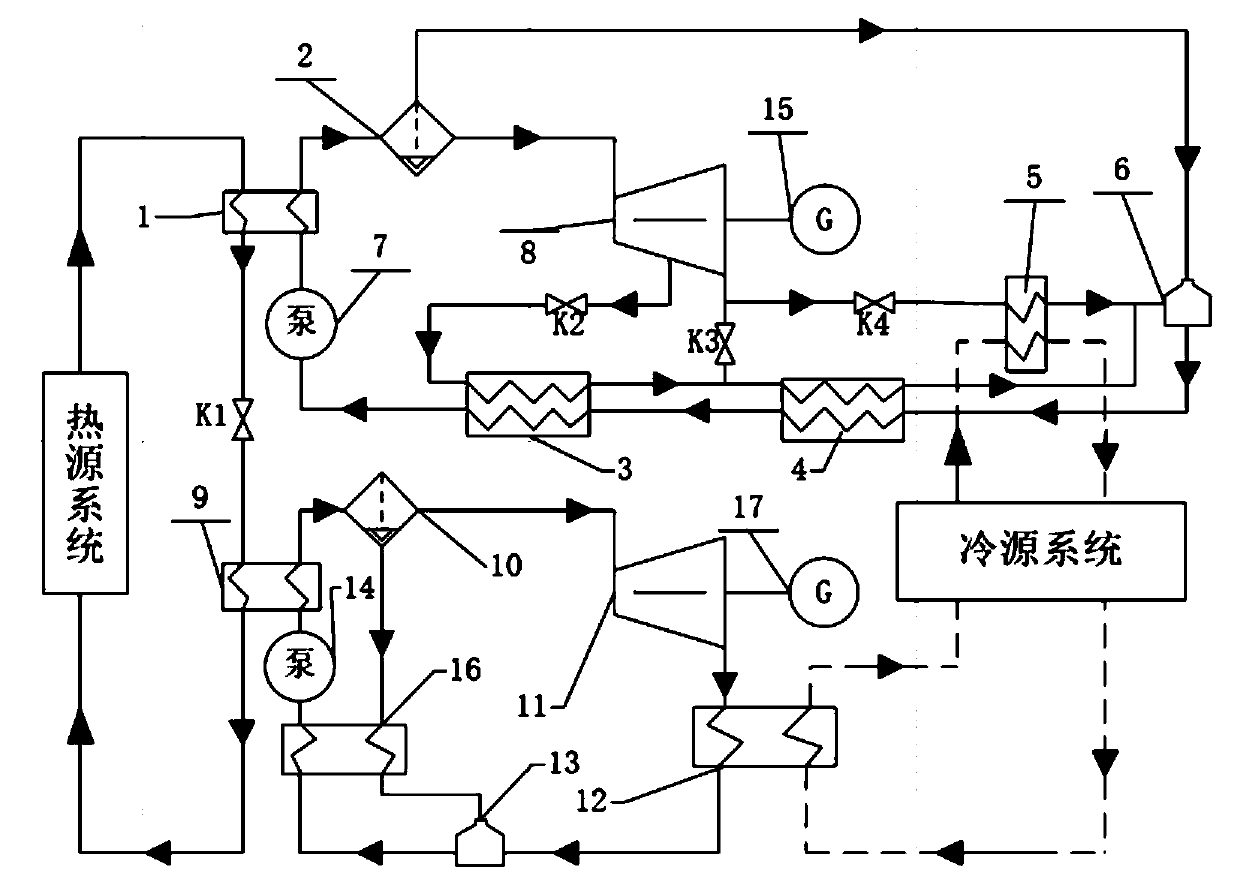

[0049] Such as figure 1 shown. The system includes a high-voltage cycle power generation system, a low-voltage cycle power generation system, a cold source system, and a heat source system; the high-voltage power generation cycle system recycles high-grade heat from the heat source system, and the remaining low-grade heat is recycled by low-pressure cycle. The cold source system is responsible for providing the cold energy required by the two cycles, and the heat source system provides the heat of the entire system.

[0050] As a preferred example of the present invention, the high-pressure cycle includes a liquid separator 2, an expander 8, an extraction steam regenerator 3, an exhaust steam regenerator 4, a condenser 5, and a liquid collector connected in sequence to form a closed cycle. 6, booster pump 7; the high-pressure cycle power generation system exchanges heat with the heat source through the high-pressure evaporator 1; the extraction steam and exhaust steam of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com