Complete equipment of system for converting conduction oil waste heat into steam and use method of equipment

A technology for steam systems and complete sets of equipment, which is applied in the field of heat transfer oil waste heat conversion steam system complete sets of equipment, which can solve problems such as complex equipment structure, unreasonable use of waste heat, and insufficient recovery of high-temperature heat transfer oil waste heat, etc., to prolong heat exchange time and waste heat Sufficient recovery and improved heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

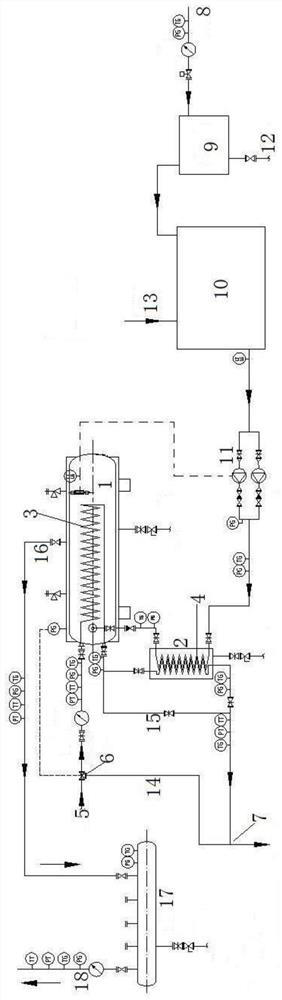

[0028] Example 1 A complete set of equipment for heat transfer oil waste heat conversion steam system

[0029] Such as figure 1 In the shown embodiment, a complete set of heat transfer oil waste heat conversion steam system includes a heat exchange system, a water treatment system, a heat transfer oil delivery system and a steam treatment system, wherein:

[0030] The heat exchange system includes a steam generator 1 and a water heater 2 communicated with the steam generator 1. The steam generator 1 is provided with a heat transfer oil delivery pipe 3, and the end of the heat transfer oil delivery pipe 3 is connected to the inner cavity of the water heater 2. Connected, the water heater 2 is provided with a water body delivery pipe 4, and the end of the water body delivery pipe 4 communicates with the inner cavity of the steam generator 1;

[0031] The heat transfer oil delivery system includes a heat transfer oil inlet 5, a three-way temperature control valve 6 and a heat tr...

Embodiment 2

[0041] Embodiment 2 A method of using a complete set of equipment for heat transfer oil waste heat conversion steam system

[0042] A method for using a complete set of equipment for heat transfer oil waste heat conversion steam system, comprising the following steps:

[0043] (1) Water treatment route: the water body enters the soft water tank 10 for storage after undergoing water quality treatment by the softening equipment, and the stored water body sends normal-temperature soft water into the water body delivery pipe 4 of the water heater 2 through the water supply pump unit 11 for pre-heating, The preheated water enters the inner chamber of the steam generator 1 to produce steam;

[0044] (2) Heat transfer oil treatment route: the original heat transfer oil pipeline of the industrial furnace production system is connected to the heat transfer oil inlet 5, and the heat transfer oil enters the heat transfer oil delivery pipe 3 of the steam generator 1 through the three-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com