Metallurgical furnace waste heat utilizing device

A metallurgical furnace and waste heat technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as large dust content in flue gas, reduced heat exchange efficiency, and increased investment in waste heat systems, achieving high heat exchange efficiency and improving economic efficiency value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

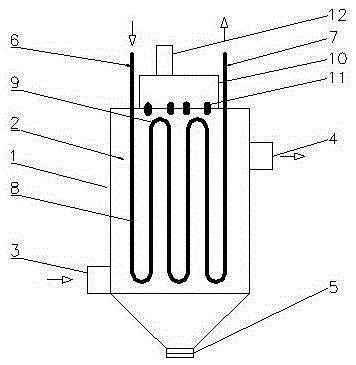

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0011] Such as figure 1 As shown, a metallurgical furnace waste heat utilization device includes a heat exchange box 1 and a heat exchange column tube 2 vertically arranged in the heat exchange box 1. The heat exchange box 1 has an air inlet 3, an air outlet 4 and a heat exchange The dust collection port 5 at the bottom of the box 1, the water inlet 6 and the water outlet 7 of the heat exchange tube 2 are arranged on the top of the heat exchange box 1, and the heat exchange tube 2 includes several vertical tubes 8 and a connecting tube for connecting the vertical tubes 8. The top of the heat exchange box 1 is provided with a sealed water tank 10, the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com