Activated carbon processing equipment

A processing equipment and activated carbon technology, applied in the field of activated carbon processing equipment, can solve the problems of uneven heating, large heat loss, large loss of carbonized material, etc., and achieve the effect of reducing heat loss, sufficient heat, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

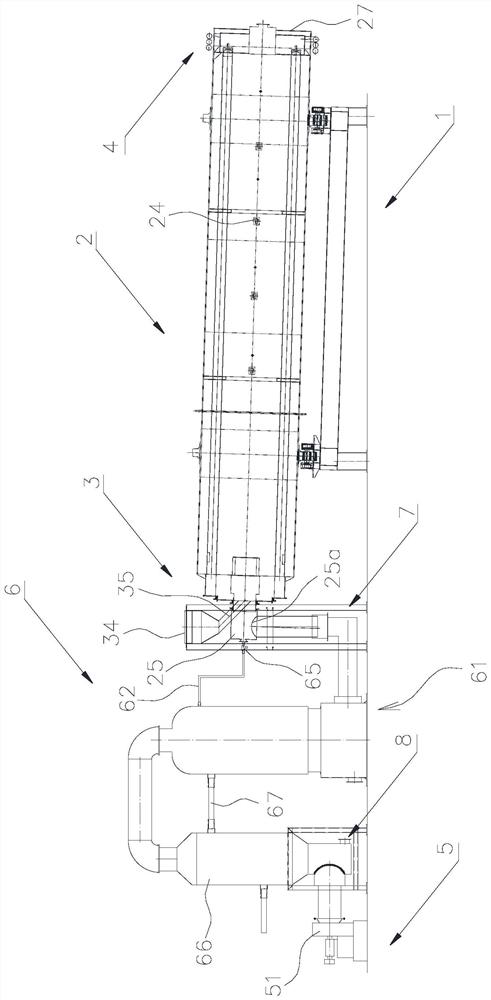

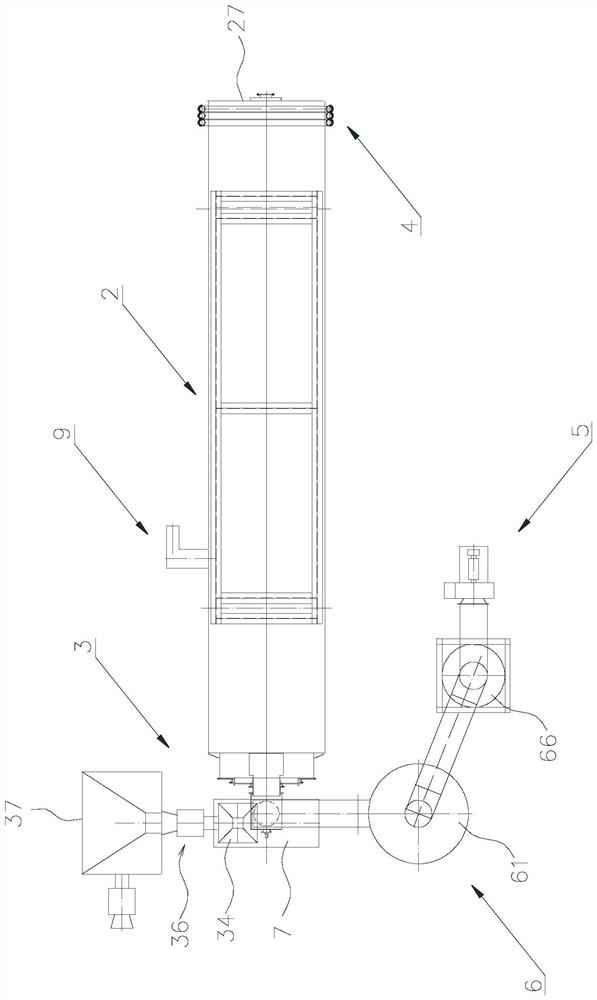

[0058] Such as figure 1 with figure 2 As shown, a kind of activated carbon processing equipment in this embodiment includes a base 1 and an activation furnace 2 arranged on the base 1 through a rotary drive mechanism 9. The activation furnace 2 is inclined downward from the feed end to the discharge end. The two ends of the activation furnace 2 are respectively sealed and installed with a self-feeding device 3 and a discharging device 4.

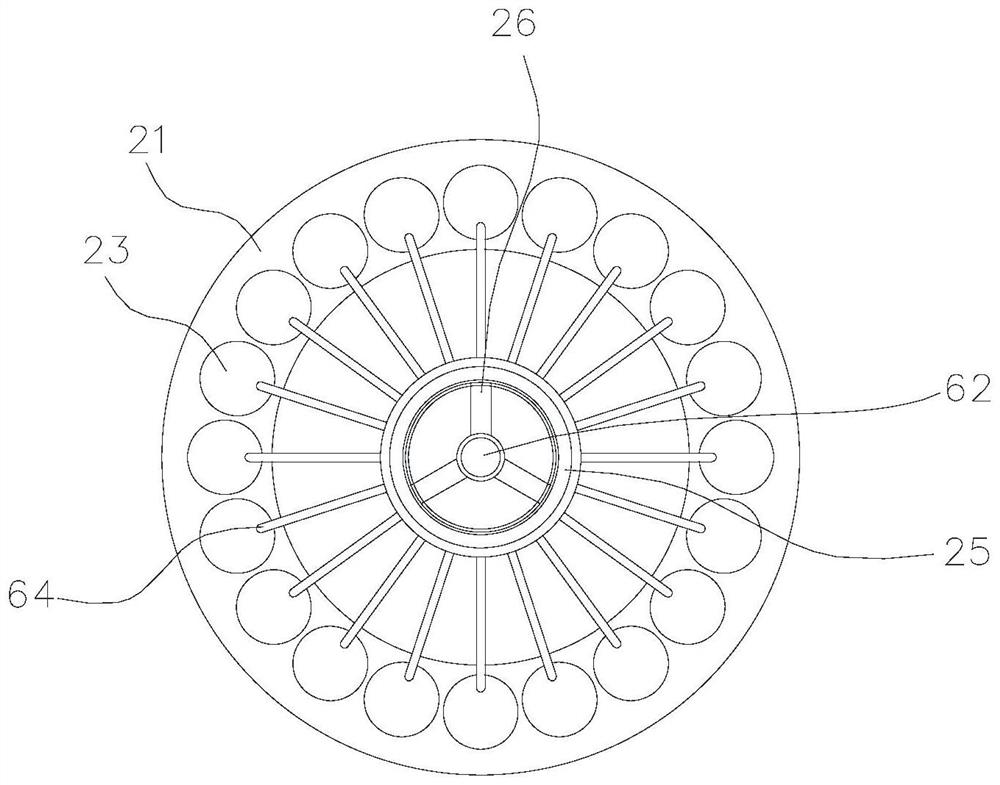

[0059] Such as image 3 with Figure 4 As shown, the activation furnace 2 of the present embodiment includes a furnace body 21, and a combustion chamber 22 and a plurality of activation channels 23 extending axially along the furnace body 21 are formed in the furnace body 21; In the center of the furnace body 21 , the inner diameters of the activation channels 23 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com