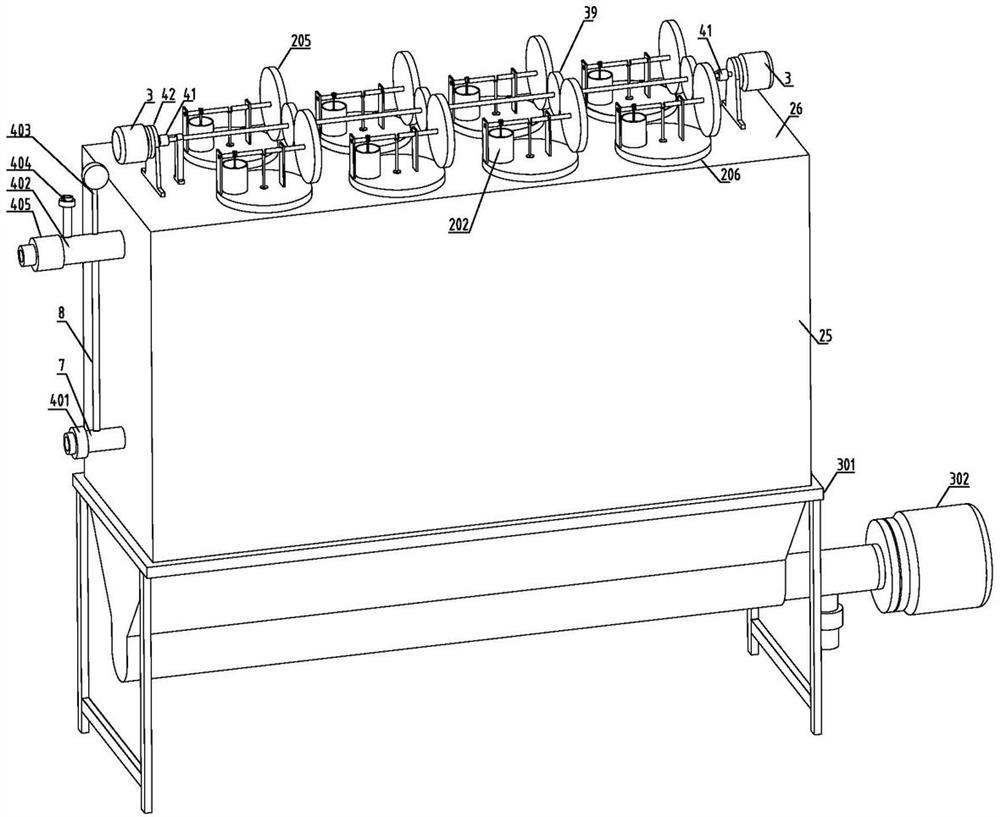

Hot flue gas purification and waste heat power generation integrated device

A technology of waste heat power generation and hot flue gas, applied in the field of energy and power, can solve the problems of many recycling links, large space occupation, long process, etc., to improve energy efficiency, energy saving and emission reduction, improve heat exchange efficiency, and fully recover waste heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

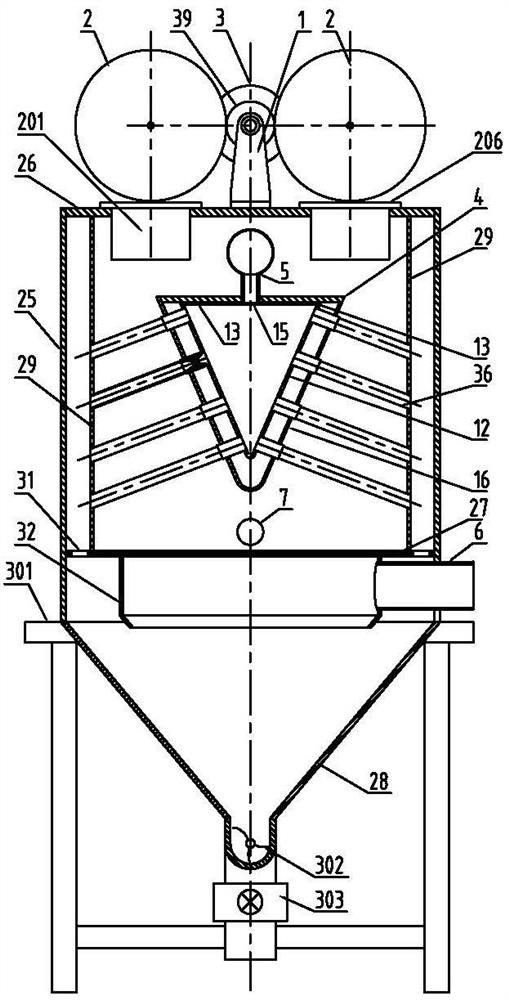

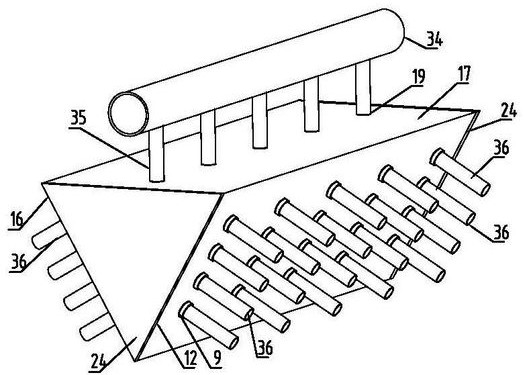

[0032] Embodiment 1: The present invention is used for cooling and waste heat power generation of furnace top gas with a temperature of 180°C, high content of superheated steam, dust, low-boiling point organic volatiles and a large amount of superheated steam. Components and each component is connected and assembled, adopting 8 low-temperature difference Stirling engines 2, two power generators 3 with a power of 10kw are respectively fixed on the two ends of the transmission shaft 37, and the height of the cylindrical shell 25 is 4 meters and wide. 3 meters and a length of 6 meters, the length of the air-flow uniform distribution device 4 is 5 meters, and the width is 1.2 meters. The inner diameter is 300mm, and the diameter of the cooling gas outlet pipe 6 is 250mm. When in use, the intake main pipe 34 (through the externally equipped hot gas valve) is connected to the furnace top gas, and the cooling gas outlet pipe 6 is connected to the outlet pipeline through the externally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com