CSP heating furnace flue gas recirculation waste heat recovery system

A waste heat recovery system and flue gas recirculation technology, applied in heat treatment furnaces, lighting and heating equipment, furnaces, etc., can solve the problems affecting the heat exchange effect of heat exchange equipment, affecting the heat exchange absorption effect and heat exchange efficiency of heat exchange equipment, Trouble and other problems, to achieve the effect of avoiding adhesion deposition, avoiding the formation of scale, and prolonging the circulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

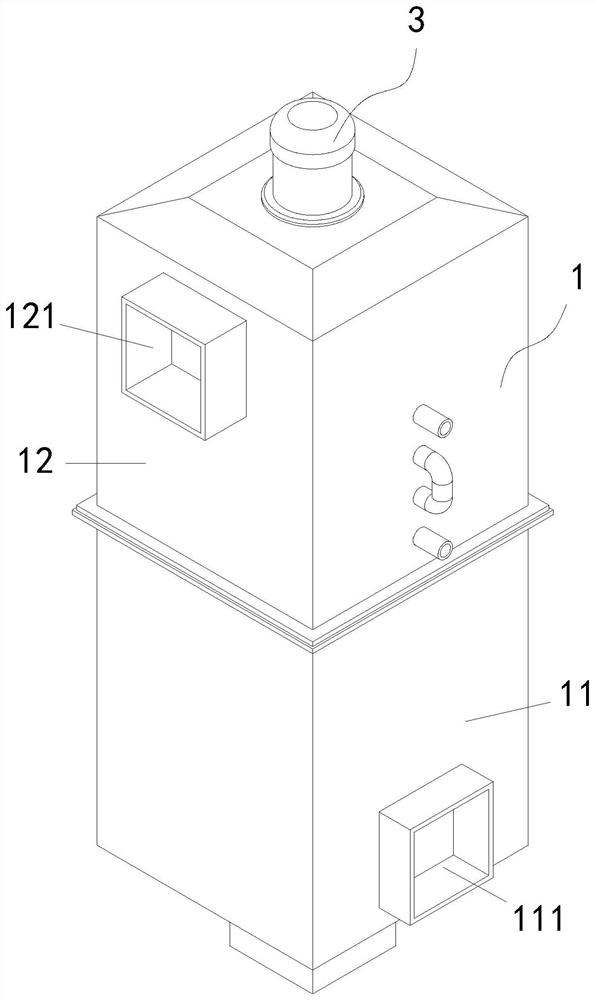

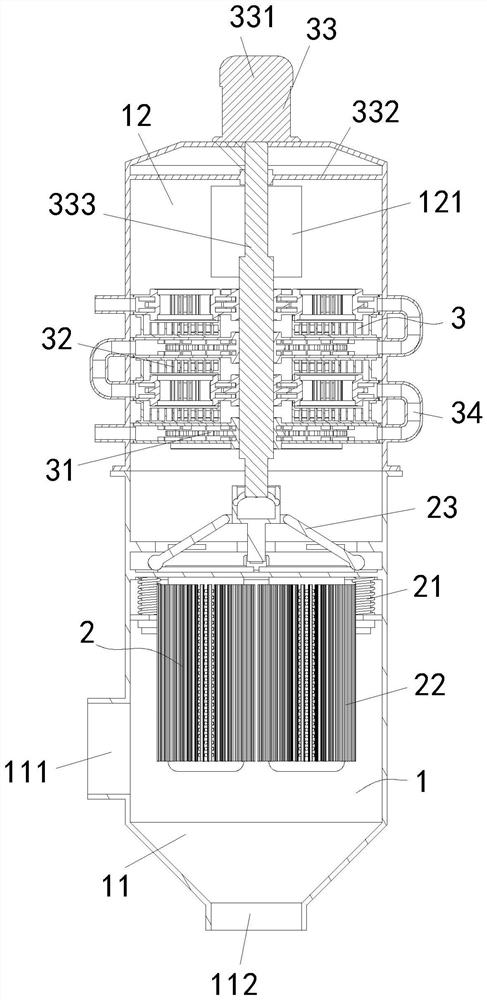

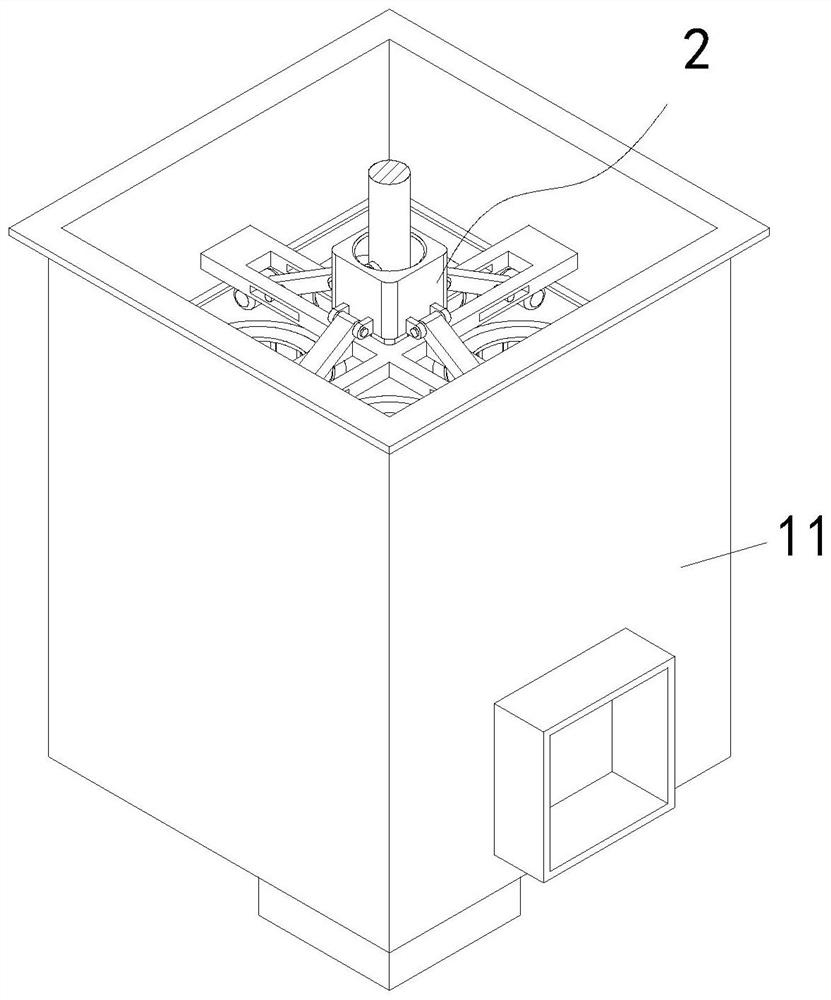

[0037] Such as figure 1 and figure 2 As shown, a CSP heating furnace flue gas recirculation waste heat recovery system includes a working chamber 1, a flue gas filtering device 2 and a waste heat recovery device 3; the working chamber 1 includes a square filter chamber 11 and is welded and fixed on the top of the filter chamber 11 The recovery bin 12 is a square structure, the flue gas filter device 2 is assembled in the filter bin 11, and the waste heat recovery device 3 is assembled on the recovery bin 12; An ash bin 112 is provided at the bottom of the bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com