Integration circuit integrated structure

A circuit integration and circuit layer technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of shortening the life of electronic components, narrow application range, low power supply efficiency, etc., to avoid inaccurate coverage positions and low cost , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

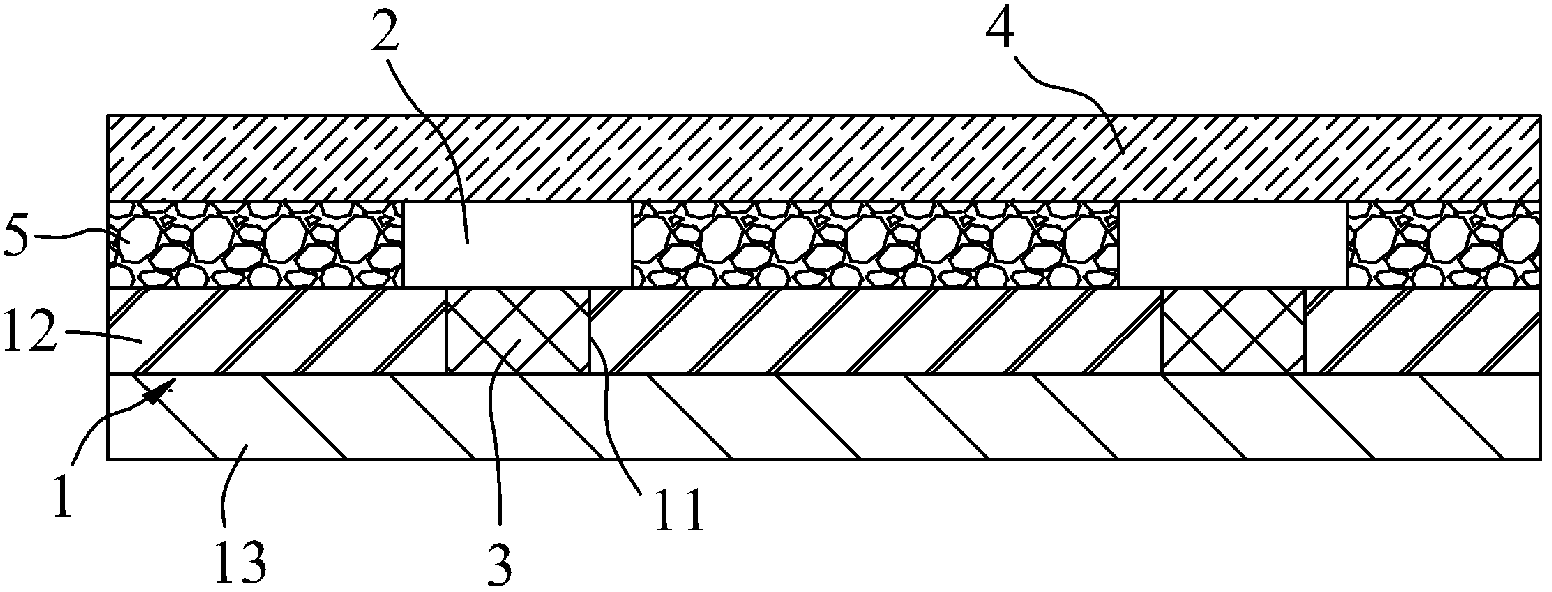

[0027] Such as figure 1 The integrated circuit integration structure shown includes a circuit substrate 1 and electronic components 2 arranged on the circuit substrate 1. The circuit substrate 1 can be set in different shapes according to needs, and the electronic components 2 can be set in different types according to the needs of circuit functions. and different quantities. The thermal conduction hole 11 is provided on the circuit substrate 1 , and is correspondingly arranged in different shapes according to the shape of the electronic component 2 , such as a circle or a square. The heat conduction holes 11 are correspondingly located below each electronic component 2, and the heat conduction holes 11 are filled with a heat conduction insulating layer 3, which is made of silicone grease, and heat conduction silica gel or heat conduction resin can also be used. The heat conduction insulation layers 3 correspond to their respective positions. The electronic components 2 are i...

Embodiment 2

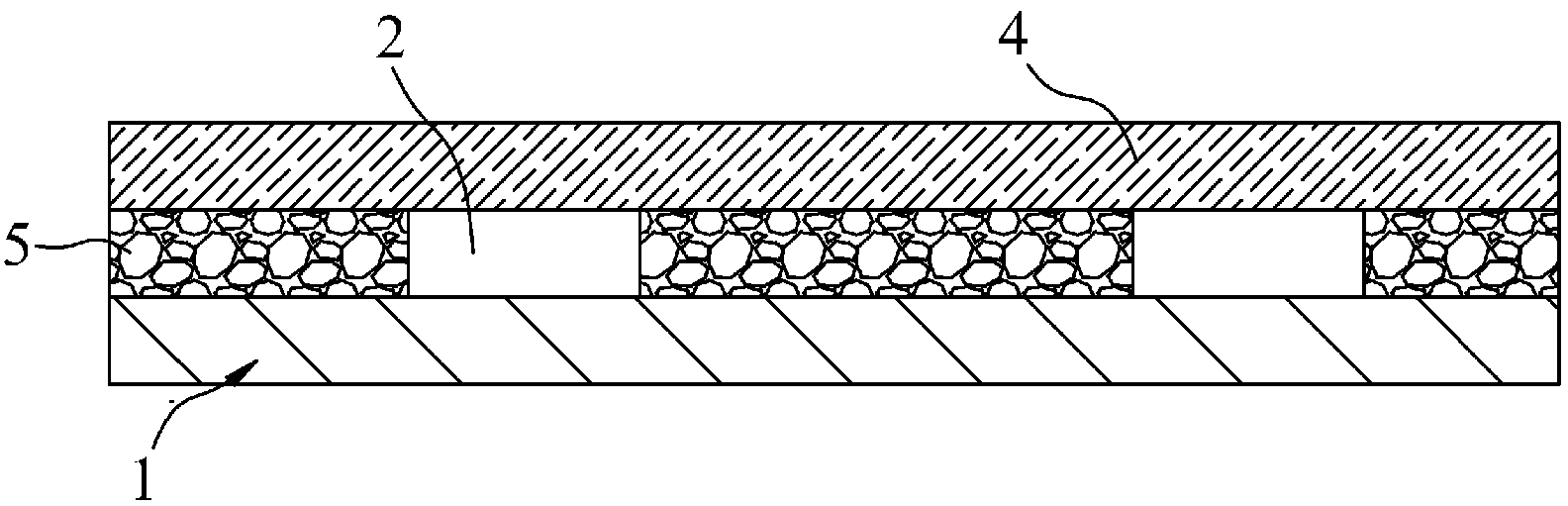

[0031] Such as figure 2 Shown is the second embodiment of the integrated circuit integration structure of the present invention. The difference between the second embodiment and the first embodiment is that the circuit substrate 1 is set as a ceramic substrate, which can reduce the volume of the structure and adapt to the narrow environment.

Embodiment 3

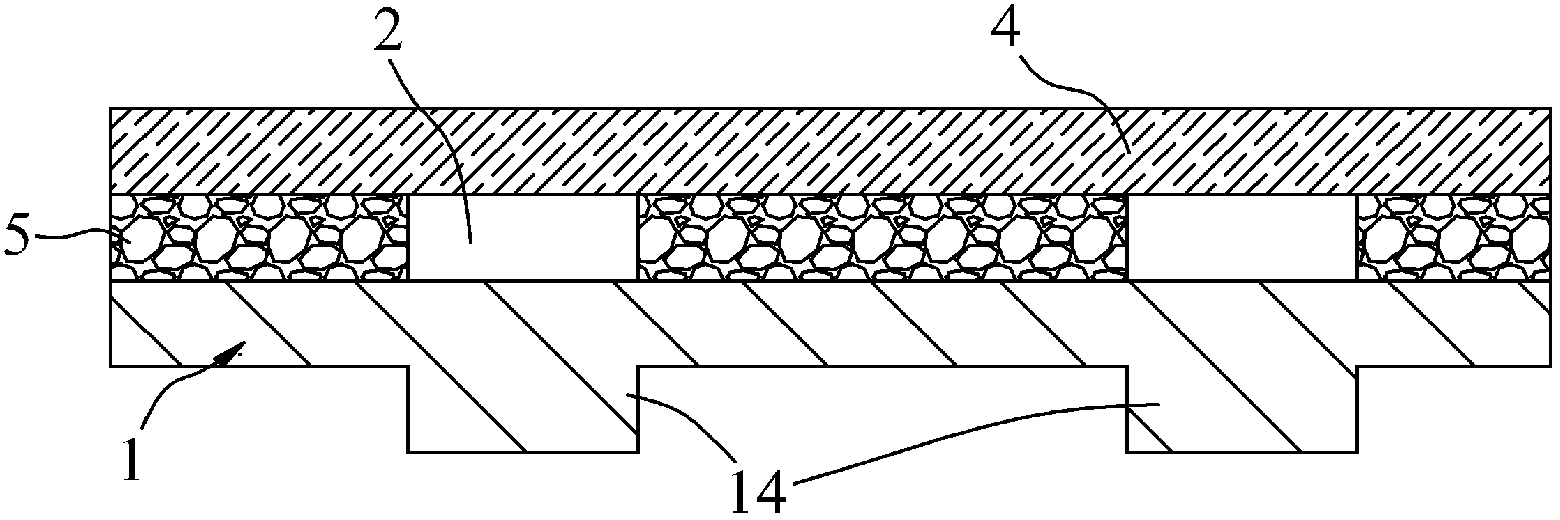

[0033] Such as image 3 Shown is the third embodiment of the integrated circuit integration structure of the present invention. The difference between the third embodiment and the second embodiment is that the lower end of the circuit substrate 1 has end pins 14 for auxiliary heat dissipation, and each end pin 14 is a One pair is located below the heat conduction hole 11 , conducts heat to the outside through the end pin 14 , and enhances the heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com