Photovoltaic cells

A photovoltaic device, conductivity type technology, applied in the field of photovoltaic cells, can solve problems such as low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

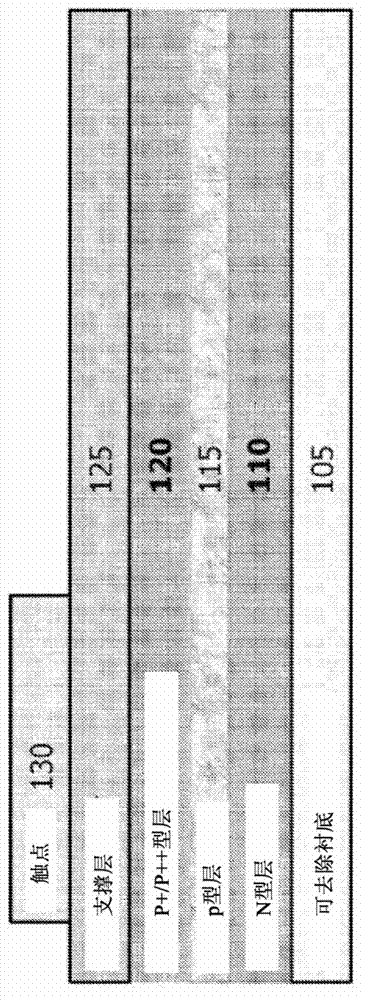

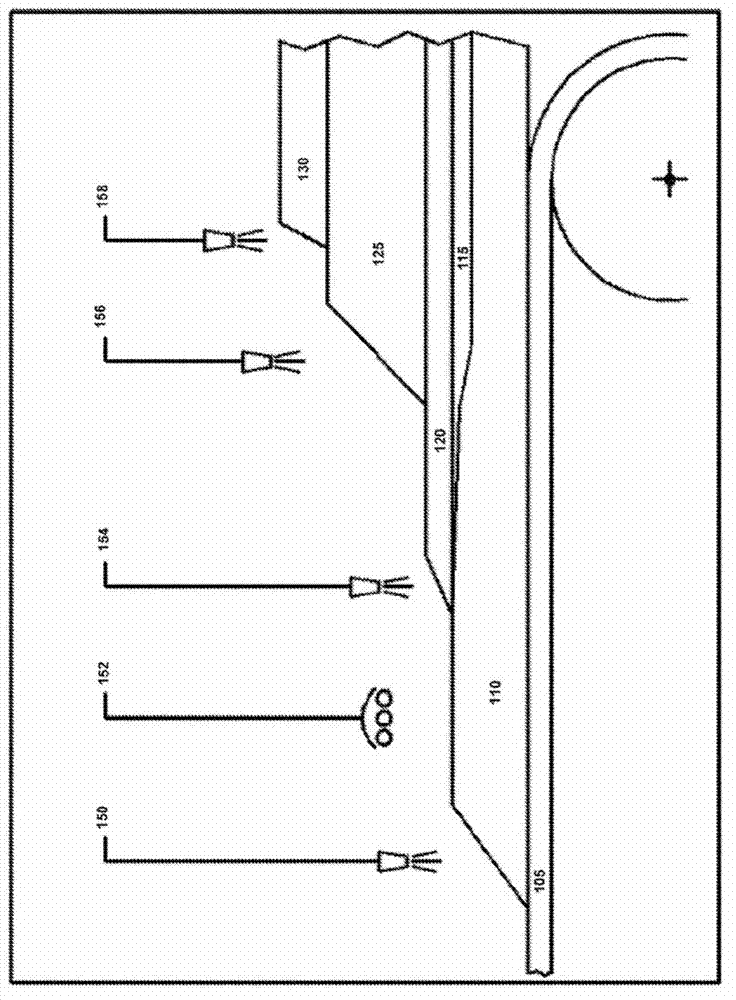

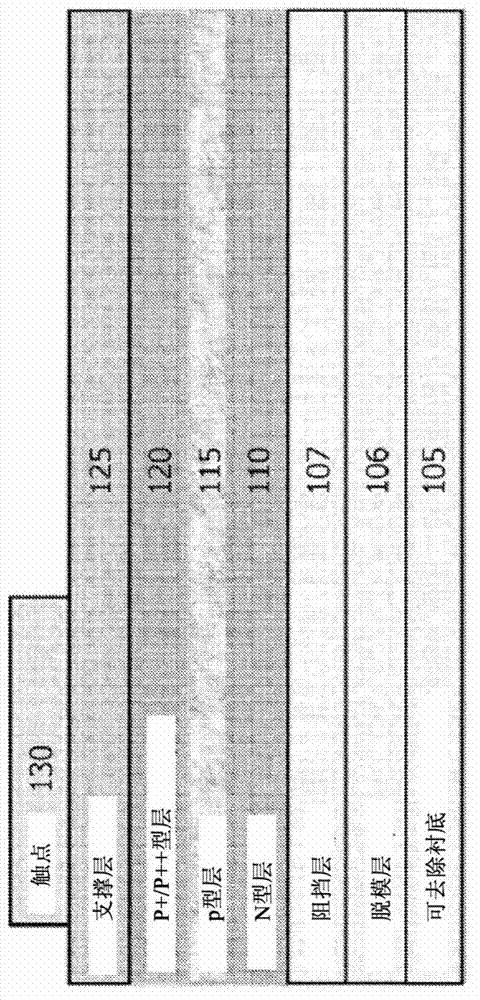

[0016] In some embodiments, as shown in FIG. 1 , on a flexible, supported material such as stainless steel sheet, graphite foil, graphite-coated flexible foil, graphite-coated stainless steel sheet, or other material suitable for roll-to-roll deposition, 1. Depositing a high-purity n-type silicon layer 110 on the removable substrate 105 . The thickness of the high purity n-type silicon layer may range from about 0.01 microns to greater than 100 microns. A release layer 106, such as silicon nitride, may be applied to the flexible substrate prior to depositing the n-type silicon layer on the flexible, supporting, removable substrate. Deposition processes 150 and 154 may be any method or combination of methods including CVD, PVD, MOCVD, PECVD, RF-PECVD, and high purity plasma spraying, among other processes known to those skilled in the art.

[0017] In some embodiments, the deposited n-type silicon layer is then recrystallized to form the light absorbing layer of the solar cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com