Dynamic screen hole rotary screen surface automatic-cleaning solid garbage treatment device

A technology of solid waste and treatment device, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of blocked holes and blocked holes, etc., and achieve the effects of easy operation, low noise and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

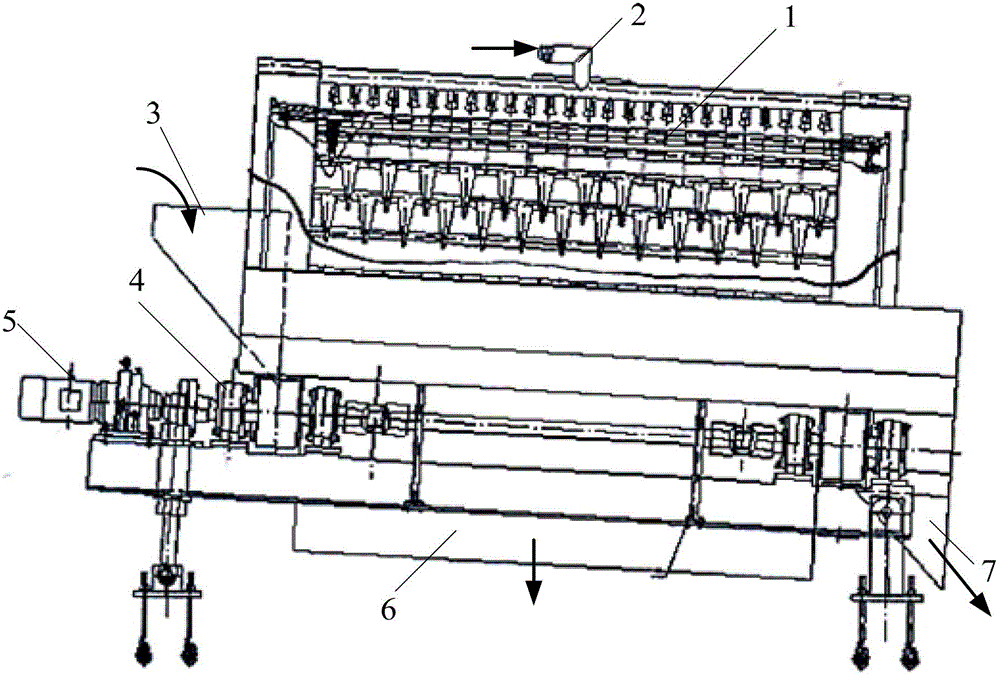

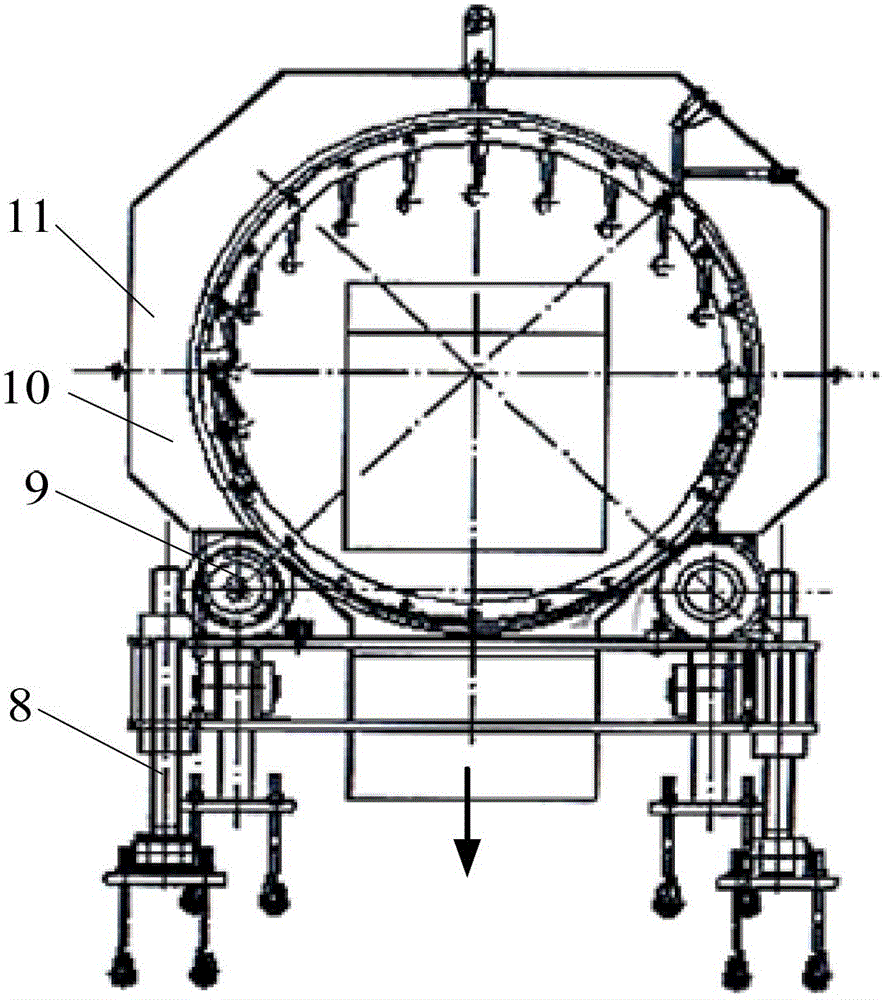

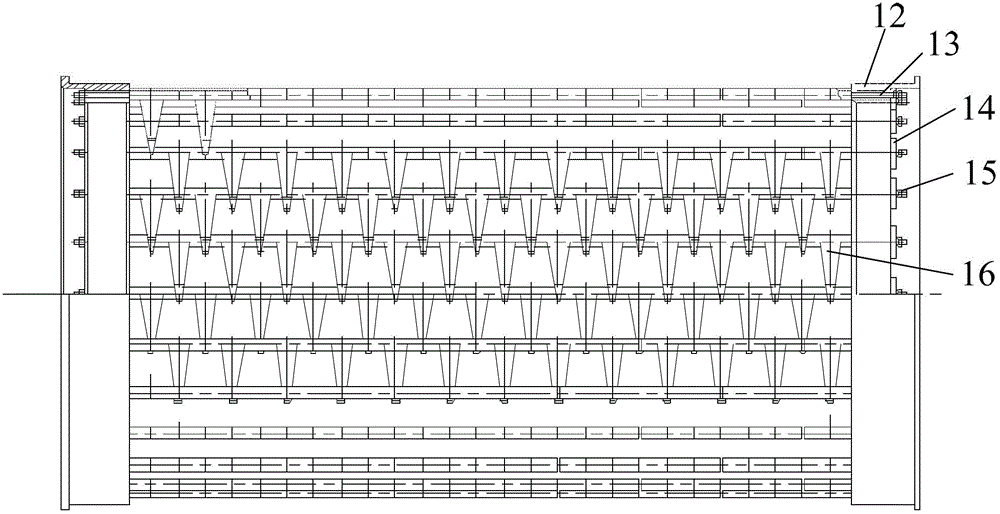

[0020] The main concept of the present invention is: a dynamic sieve hole rotary screen surface self-cleaning solid waste treatment device, the device mainly includes a dynamic sieve hole roller device 1, an auxiliary hole cleaning device 2, a feeding hopper 3, a transmission device 4, and a motor 5 , undersize material discharge opening 6, oversize material discharge opening 7, adjustable support device 8, roller 9, lower sealing cover 10 and upper sealing cover 11, such as figure 1 shown.

[0021] The decelerated motor 5 is connected with the transmission device 4 through a coupling to drive the dynamic screen drum device 1 to rotate around its axis. The dynamic screen drum device 1 is obliquely installed on the roller 9 of the adjustable support device 8. When the material enters the dynamic screen drum device 1, due to the inclination of the dynamic screen drum device 1 (7°~10° from the horizontal) and Rotate to make the materials on the sieve surface turn and roll, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com