Dust remover and dust removing process for lithium battery pole pieces

A technology of lithium battery and dust remover, which is applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc. High speed, good burr and dust, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

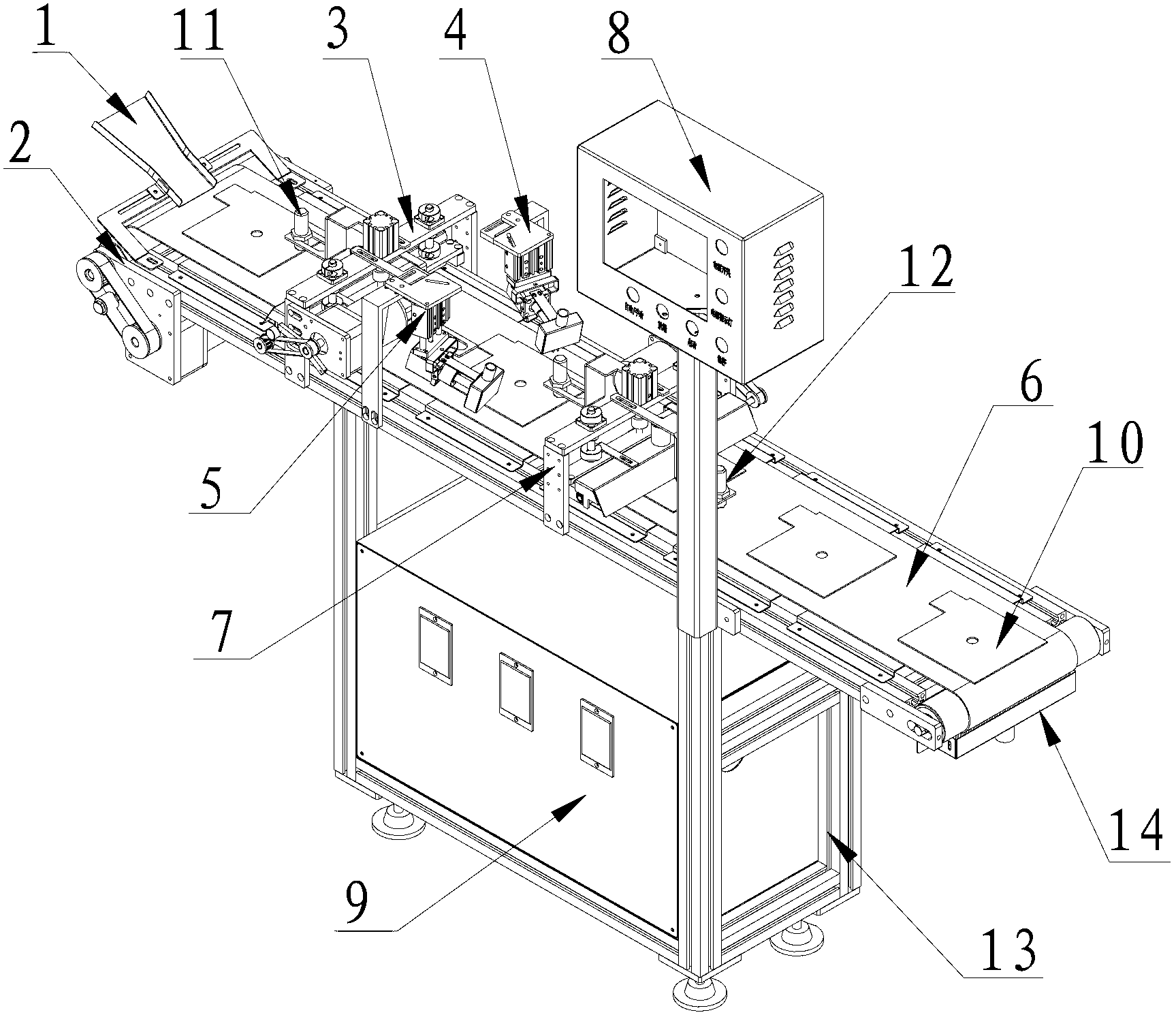

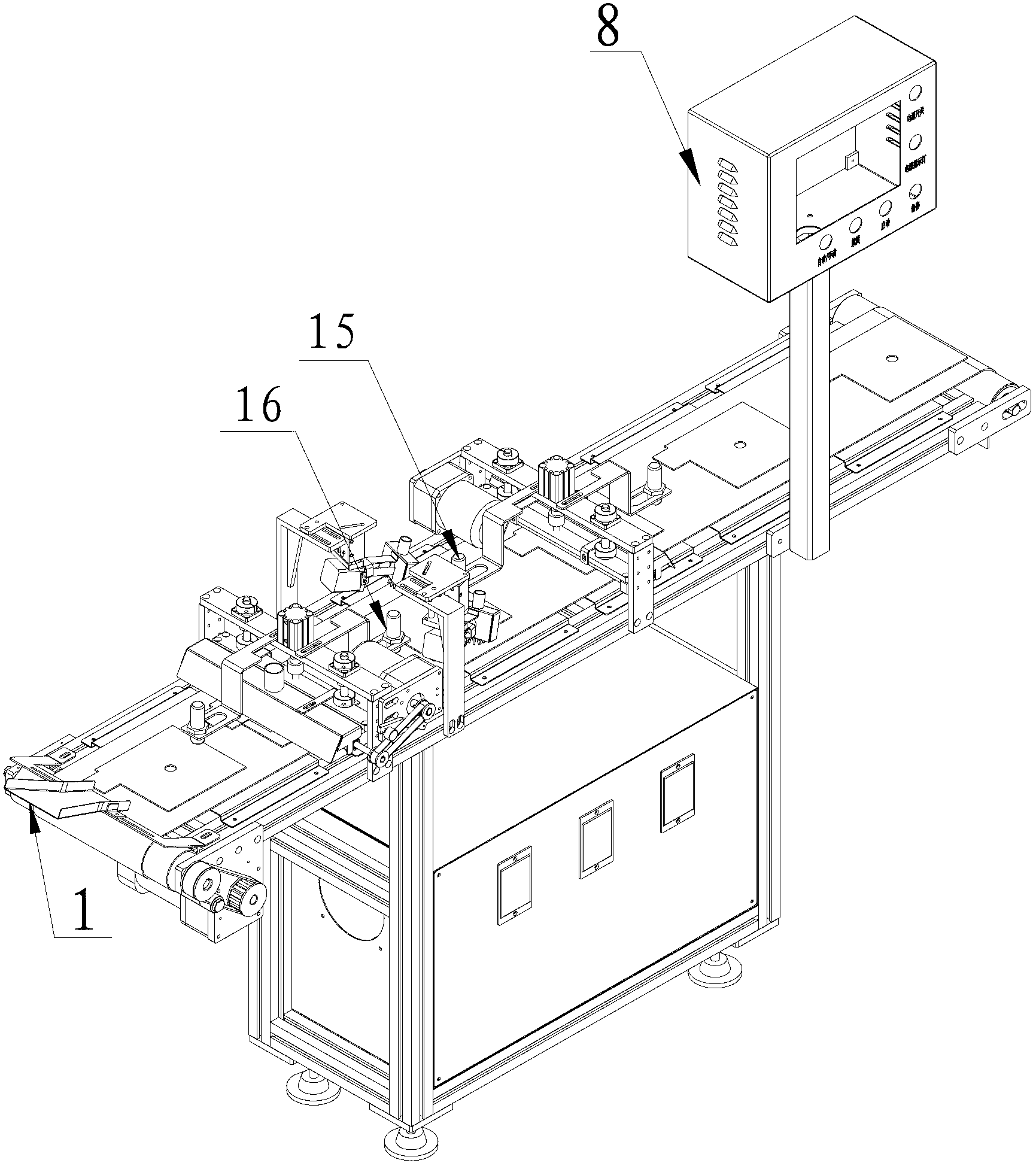

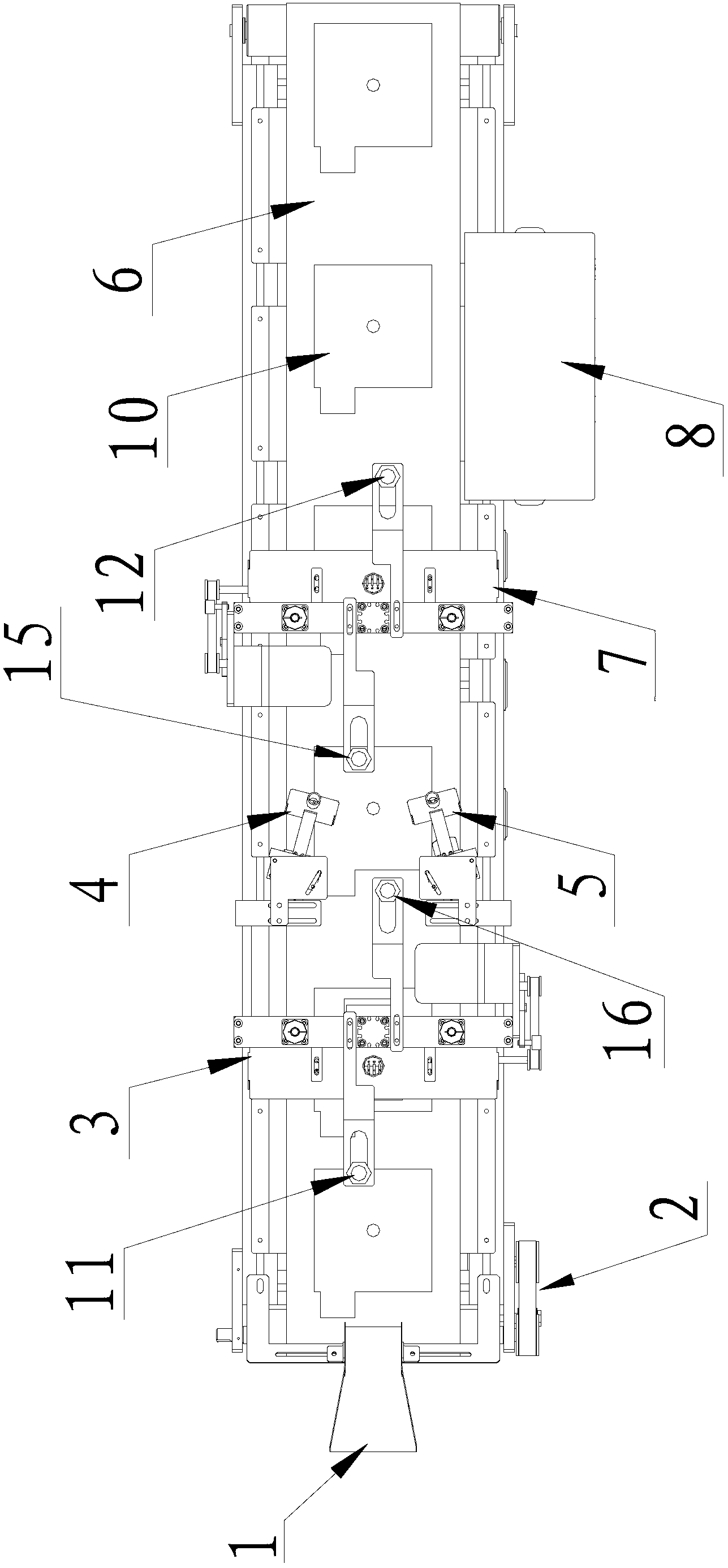

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Please refer to Figure 1-9 , the present invention provides a lithium battery pole piece powder brushing and dedusting machine, comprising a material guide device 1, a motor transmission transmission device 2, a brush assembly, a conveyor belt 6, and a frame 13, and the conveyor belt 6 is driven by the motor transmission transmission device 2, The material guide device 1, the motor conveying transmission device 2, the brush assembly and the conveyor belt 6 are all installed on the frame 13; 3. The left brush assembly for brushing and dusting the left edge of the lithium battery pole piece 10 5. The right brush assembly for brushing and dusting the right edge of the lithium battery pole piece 10 4. The brush assembly for brushing and dusting the lithium battery pole The rear brush assembly 7 at the end of the sheet 10, the material guide 1 and the front brush a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com