Application of trans-1,4-polydiene composite rubber in rubber products

A technology of composite rubber and polydiene, which is applied in tire parts, rolling resistance optimization, transportation and packaging, etc., can solve the problems of low heat generation, no application reports, small rolling resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

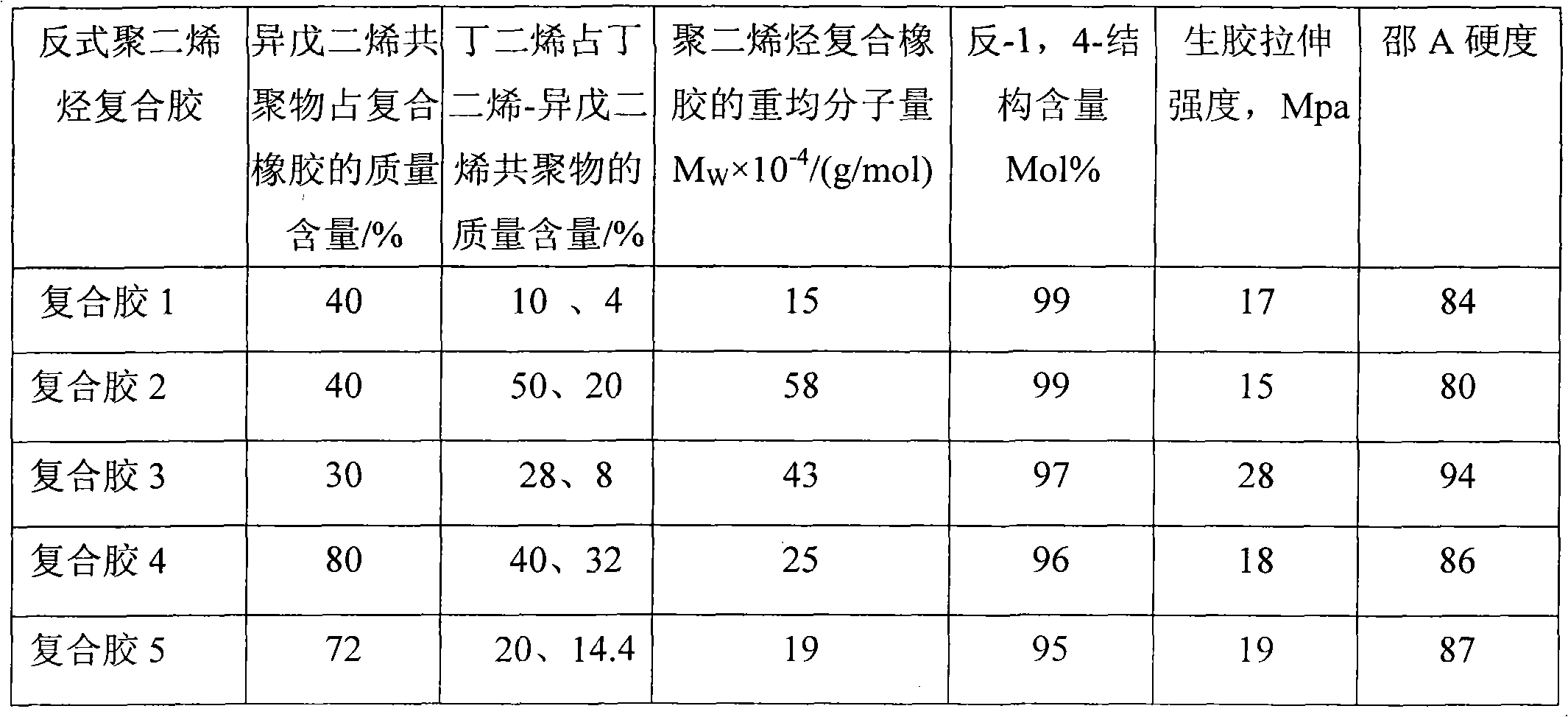

Image

Examples

Embodiment 1~4

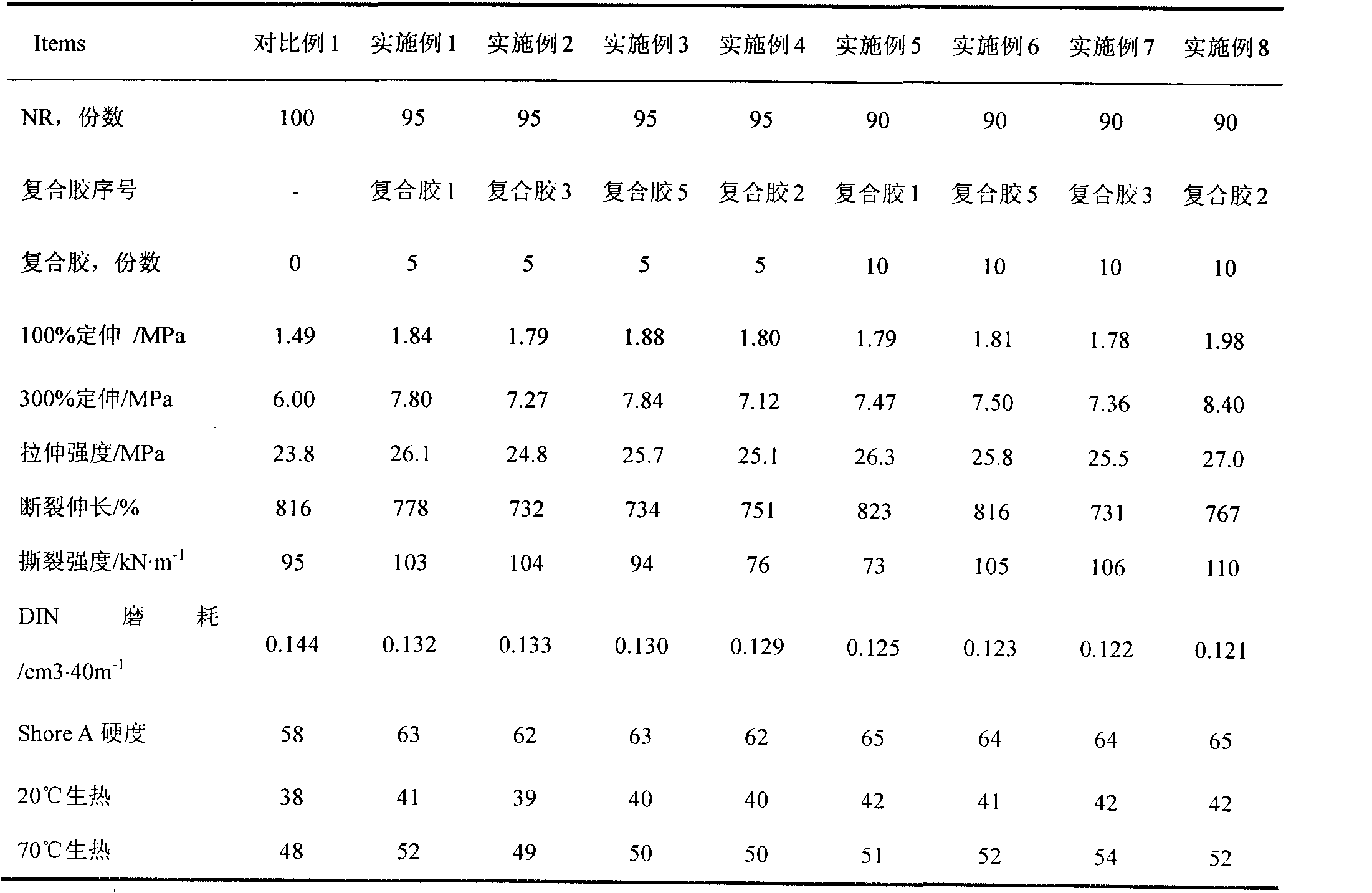

[0035] Mix 95 parts of NR and 5 parts of polydiene composite rubber with different trans-1,4-structures on a two-roll mill, according to the traditional basic formula of tire tread rubber, other additives are: carbon black N220 55 parts , 3.5 parts of zinc oxide, 2 parts of stearic acid, 1.2 parts of accelerator NS, 1.2 parts of sulfur, 1.5 parts of anti-aging agent 4010, 1.5 parts of anti-aging agent RE, 5 parts of aromatic oil, and 0.2 parts of anti-scorch agent CTP. The physical and mechanical properties of the vulcanized rubber were measured after being sliced and vulcanized, and are listed in Table 2.

Embodiment 5~8

[0037]Mix 90 parts of NR and 10 parts of polydiene composite rubber with different trans-1,4-structures on a two-roll mill, according to the traditional basic formula of tire tread rubber, other additives are: carbon black N220 55 parts , 3.5 parts of zinc oxide, 2 parts of stearic acid, 1.2 parts of accelerator NS, 1.2 parts of sulfur, 1.5 parts of anti-aging agent 4010, 1.5 parts of anti-aging agent RE, 5 parts of aromatic oil, and 0.2 parts of anti-scorch agent CTP. The physical and mechanical properties of the vulcanized rubber were measured after being sliced and vulcanized, and are listed in Table 2.

[0038] Table 2 Properties of blended vulcanizates of polydiene composite rubber with trans-1,4-structure and NR

[0039]

[0040] It can be seen from Table 2 that the NR in the tread rubber formula is partially replaced by trans-1,4-structure polydiene composite rubber, and the 100% constant elongation, 300% constant elongation and tensile strength of the rubber are c...

Embodiment 9~11

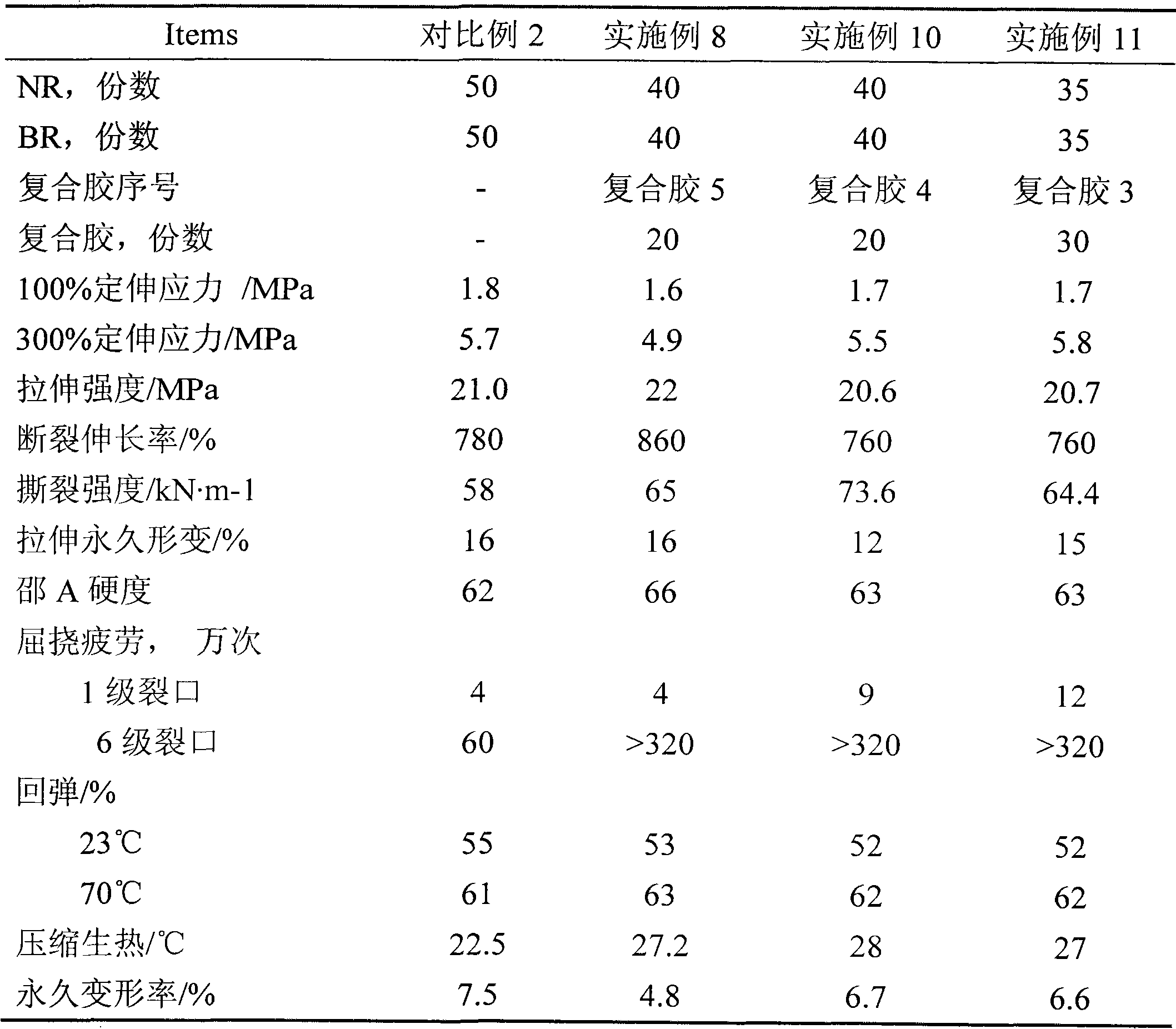

[0044] NR, BR and trans-1,4-structure polydiene composite rubber are mixed on a double-roll mill, according to the traditional basic formula of tire sidewall rubber, other additives are: carbon black N330 50 parts, zinc oxide 5 2.5 parts of stearic acid, 0.9 parts of accelerator CZ, 1 part of microcrystalline wax, 2 parts of sulfur, 2 parts of anti-aging agent 4010, 1 part of anti-aging agent 4020, 1 part of anti-aging agent RE, 7 parts of aromatic oil, anti-scorch agent CTP 0.2 copies. The physical and mechanical properties of the vulcanized rubber were measured after being sliced and vulcanized, and are listed in Table 3.

[0045] Table 3 Properties of blended vulcanizates of polydiene composite rubber with trans-1,4-structure and NR and BR

[0046]

[0047] It can be seen from Table 3 that the NR and BR in the sidewall rubber formula are partially replaced with trans-1,4-structured polydiene composite rubber, and the rubber has 100% constant elongation, 300% constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com