Emergency short circuit device and method of aluminum cell

An aluminum electrolytic cell and short-circuit device technology, which is applied in the field of short-circuit treatment of aluminum electrolytic cells, can solve problems such as dead cells and enterprise losses, and achieve the effects of accurate positioning, loss reduction and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

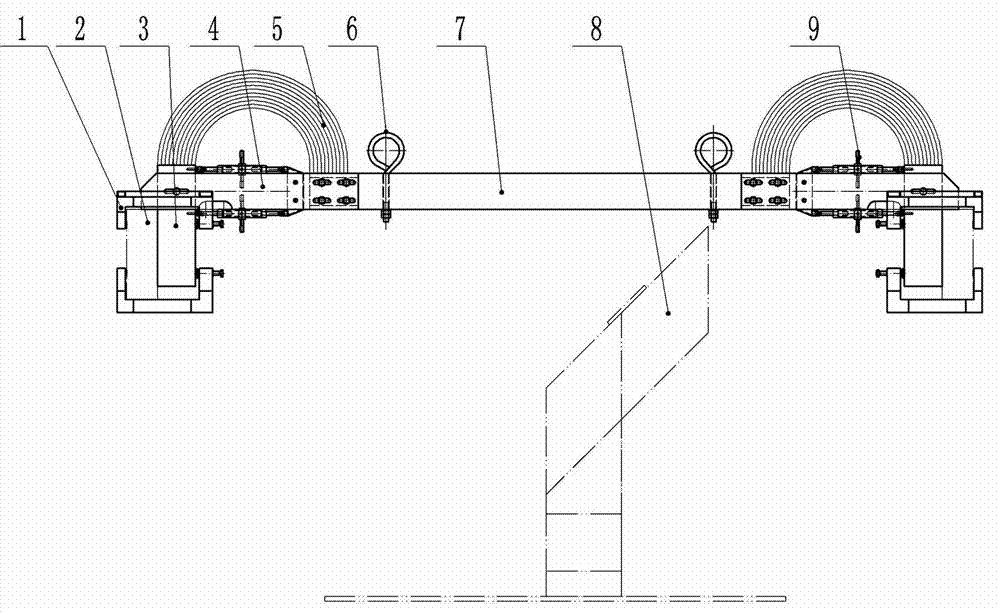

[0028] Example 1: see Figure 1~5 , A device for emergency short-circuiting of aluminum electrolytic cells, comprising a diversion bus 7, a crimping bus 3, a transition soft connection 5 and a clamp 1. Both ends of the diversion bus 7 are fixed with transition soft connections 5, and the transition soft connection The other end of 5 is welded and fixed to the crimping bus bar 3. The crimping bus bar 3 is fastened to the large anode bus bar 2 by a clamp 1. The two opposite sides of each end of the diversion bus bar 7 are respectively fixed with support beams 4, so The other end of the support beam 4 is placed on the large anode bus bar 2 of the downstream tank or the emergency tank, a distance adjuster 9 is fixed inside the crimping bus bar 3, and the other end of the distance adjuster 9 is fixed on the support beam 4 .

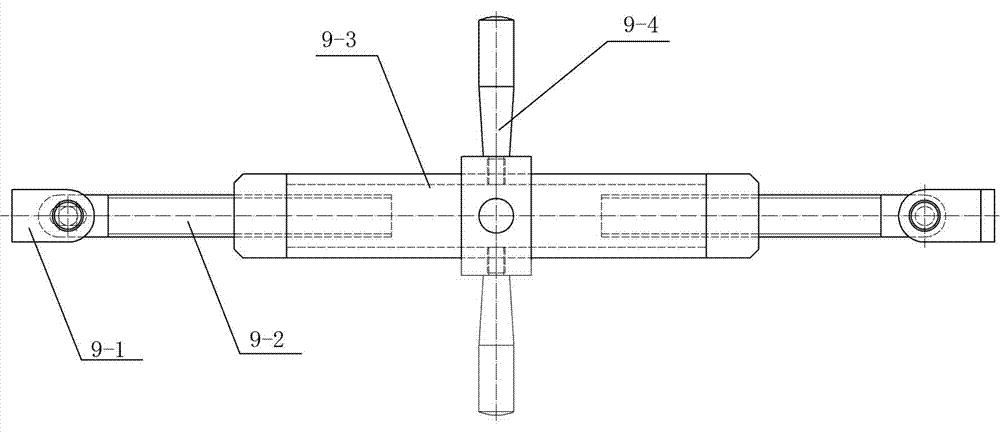

[0029] The distance adjuster 9 includes a support 9-1, a rotating screw 9-2, a wire sleeve 9-3 and a hand wheel 9-4, and the support 9-1 includes a first suppor...

Embodiment 2

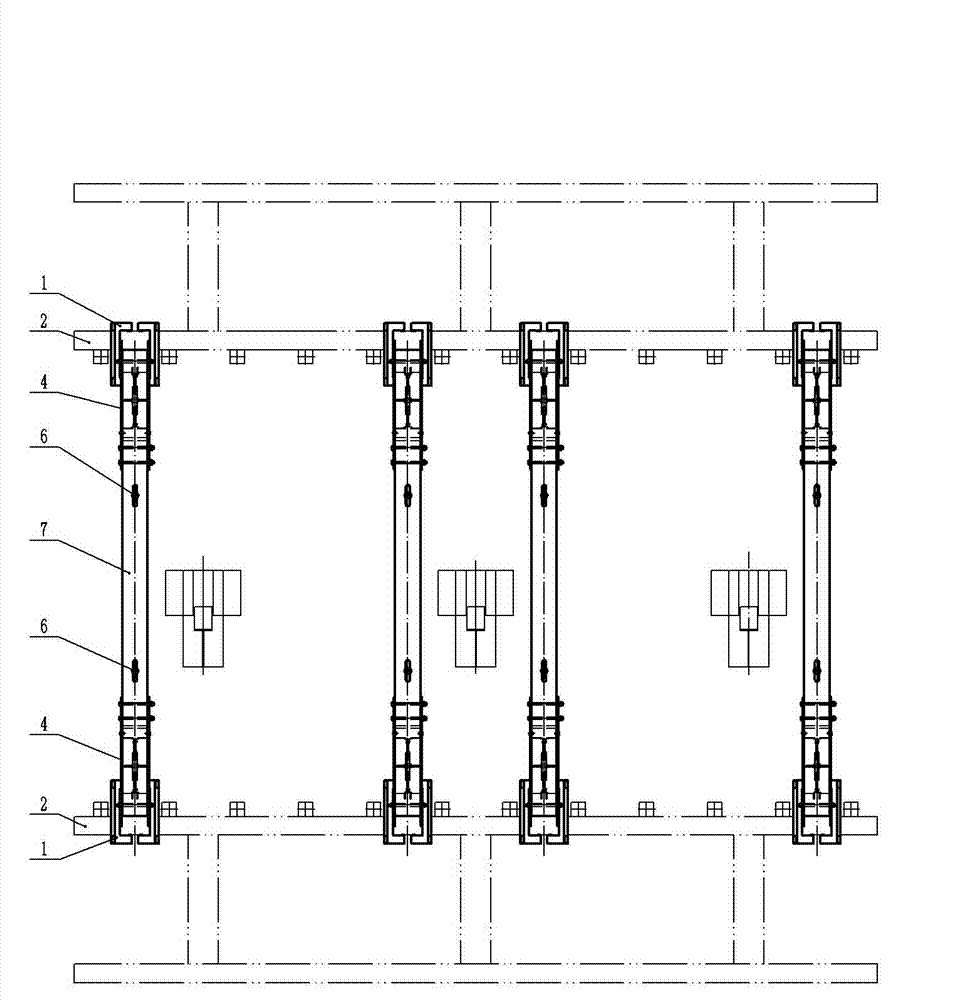

[0032] Example 2: see Figure 1~5 When one or more electrolytic cells in the electrolytic series fails, the electrolytic series is cut off, causing any part of the original short-circuit bus to be damaged, and the short-circuit bus of the accident electrolytic cell is damaged and the bus around the electrolytic cell 12 is When the accident (such as hot electrolyte around) does not meet the operating conditions, the specific steps are as follows:

[0033] 1) Use a crane to short-circuit the aluminum electrolyzer a by lifting lugs and place it on the large anode busbar on the outlet side of the accident electrolyzer and the anode busbar on the inlet side of the downstream tank, and adjust the crimping busbar through the distance regulator. The distance and angle from the large anode bus bar make the crimping surface of the crimping bus bar coincide with the outside of the large anode bus bar;

[0034] 2) Crimp the crimped busbar and the anode busbar firmly by the clamp;

[0035] 3) R...

Embodiment 3

[0040] The third embodiment is basically the same as the second embodiment, but the difference is that when an accident occurs in the electrolytic cell and the short-circuit bus bar and the column bus bar are damaged, the operation is performed according to the above method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com