A large current step-by-step transfer switch for an aluminum electrolytic cell and a step-by-step current transfer method

A transfer switch, aluminum electrolytic cell technology, applied in the field of current-on or off-current devices, can solve problems such as being less than ideal, and achieve the effects of simple structure, small footprint and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

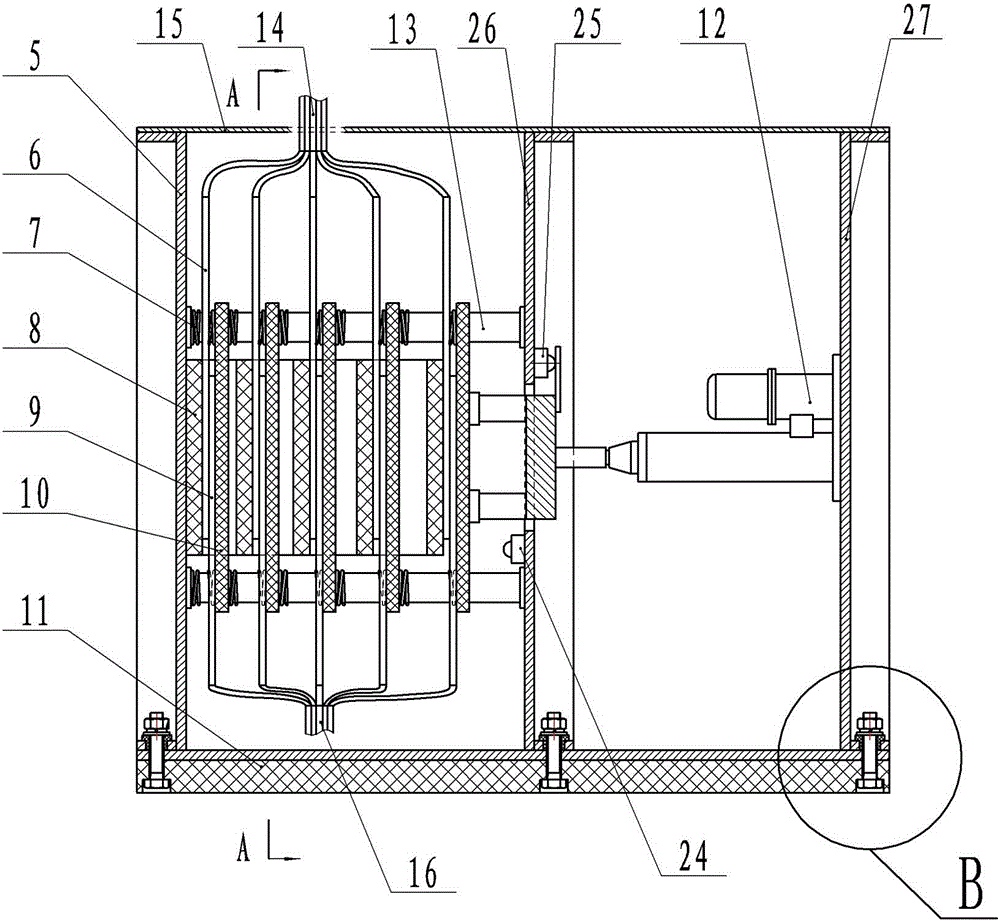

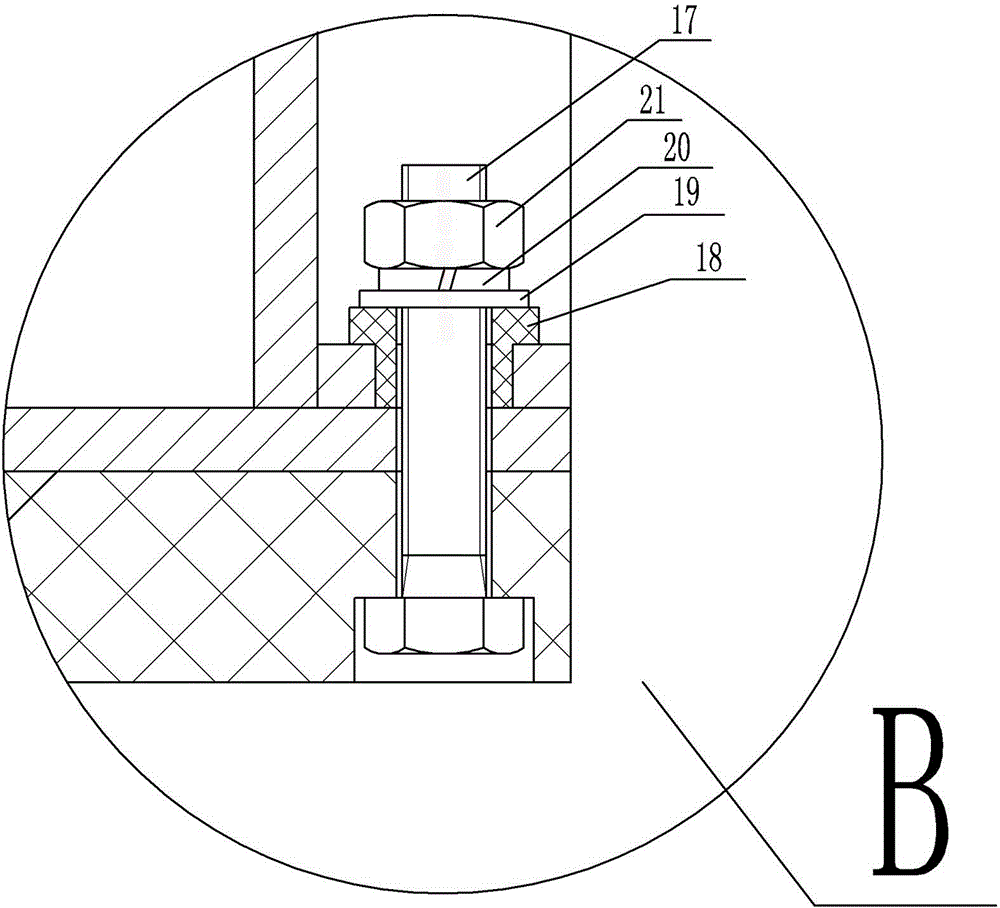

[0039] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 As shown, a step-by-step high current transfer switch for an aluminum electrolytic cell includes a support plate, a sealing cover plate 15, a switch upper and lower contact connecting plate 4, an insulating frame 8, an insulating movable crimping plate 10, and an electro-hydraulic push rod 12. The insulating base 11, the electric push rod 12 is closed and separated between the upper and lower contact connecting plates 4 of the motor synchronous forward and reverse control switch, and two are respectively fixed between the left support plate 5 and the middle support plate 26. The middle upper horizontal support shaft and the two middle lower horizontal support shafts with an insulating layer are provided with at least one pair of switch upper and lower contact connecting pl...

Embodiment 2

[0043] Example 2: see figure 1 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 As shown, the symbols in the figure that are the same as those in Embodiment 1 have the same meaning, and the same parts as those in Embodiment 1 will not be repeated. The difference is that the power moving mechanism is a rack and pinion transmission mechanism 23, and the gear The rack drive mechanism 23 is set on the support platform 22, and the upper and lower contact connecting plates of the switch are shaped as two-phase alternating and matching broken-line switch upper contact connecting plates 6a and lower contact connecting plates 9a, that is, the two phases are mutually matched. The upper and lower contact connecting plates of the broken-line switch are two intersecting and matching broken-line contact plates of two triangles with a common side, or two matching br...

Embodiment 3

[0044] Embodiment 3: The same parts as in Embodiment 1 will not be repeated, the difference is: the power moving mechanism is an electric worm gear mechanism composed of a servo motor, a worm gear, and a worm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com