Processing device for superfine fiber synthetic leather substrate with single-side compact filling layer and polyurethane filling process thereof

A technology of ultra-fine fiber and processing equipment, which is applied in the direction of textiles and papermaking, can solve the problems of restricting the application of ultra-fine fiber synthetic leather, the overall stiffness of the product, and poor peel strength, and achieve the effect of promoting high-end applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

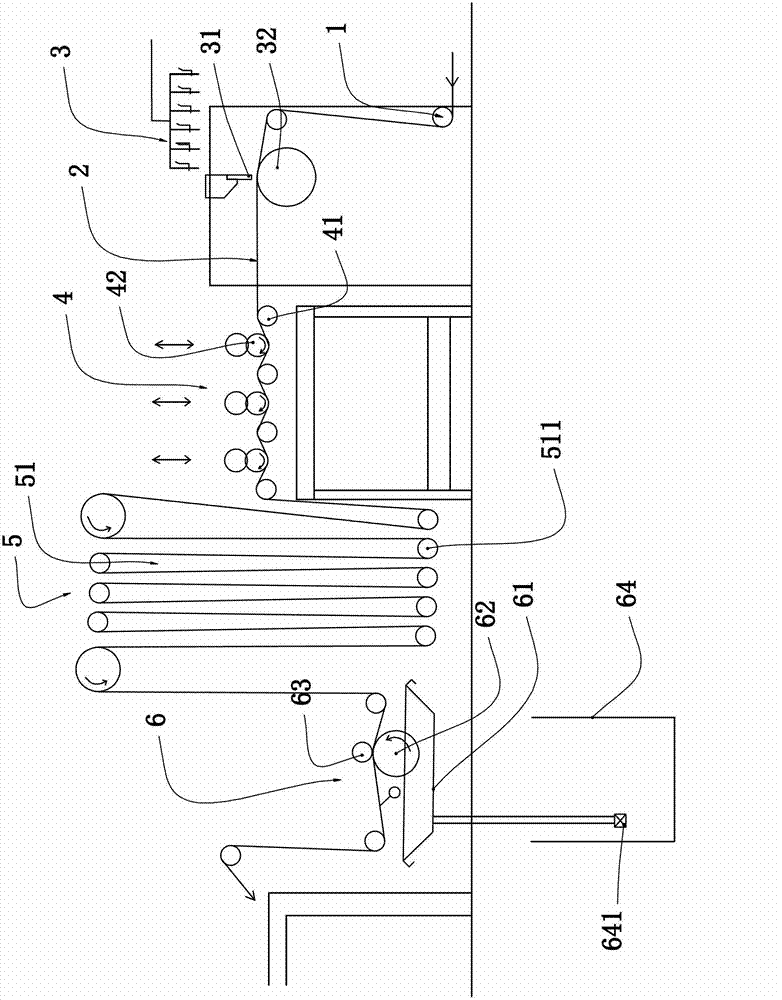

Method used

Image

Examples

Embodiment 2

[0030] Including the following procedures:

[0031](1) Arrange the ultra-fine fiber non-woven on the traction walking mechanism;

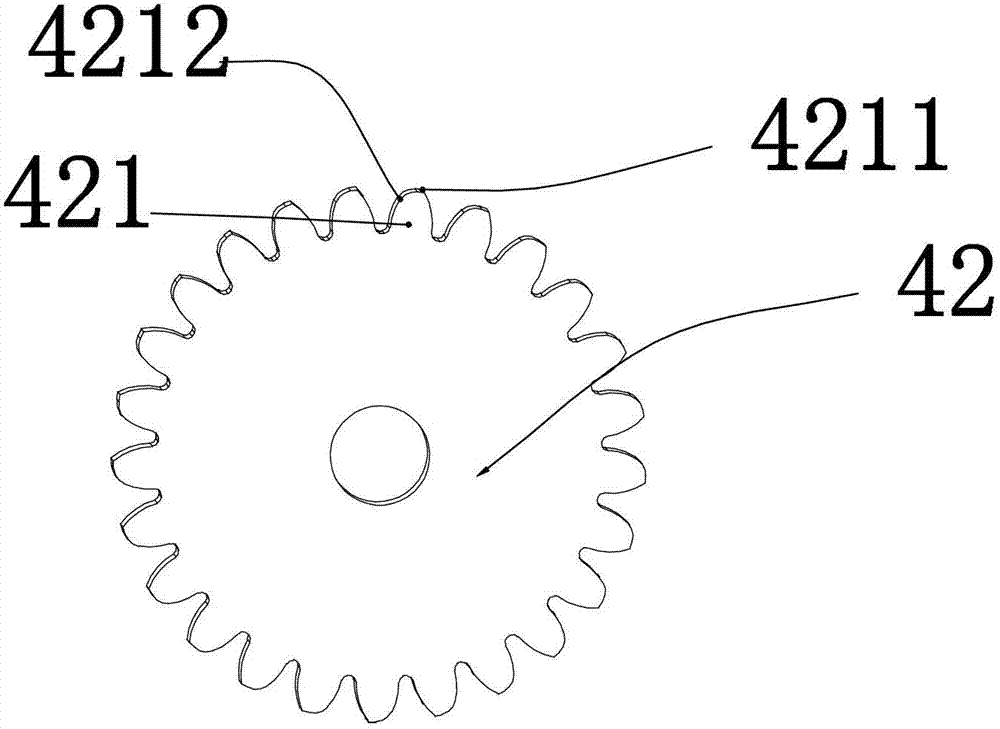

[0032] (2) Add polyurethane resin with high solid content from the feeding port. DMF solution or water-based solvent can be used as the solvent for the high solid content polyurethane resin. The solid content is 15%-35%, and the feeding amount is 500 g / m2- 1000 g / m2, and rotate the upper extrusion pressing wheel, the linear speed of the extrusion convex teeth of the upper extrusion pressing wheel is: 15 m / min-50 m / min, so that one side of the superfine fiber non-woven fabric faces The inner extrusion is filled with polyurethane resin, and the filling depth of the polyurethane resin into the microfiber non-woven fabric is at least 1 / 2 of the thickness of the entire microfiber non-woven fabric;

[0033] (3) The polyurethane resin with low solid content is loaded into the material tank in the lower coating mechanism. The solvent of the high solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com