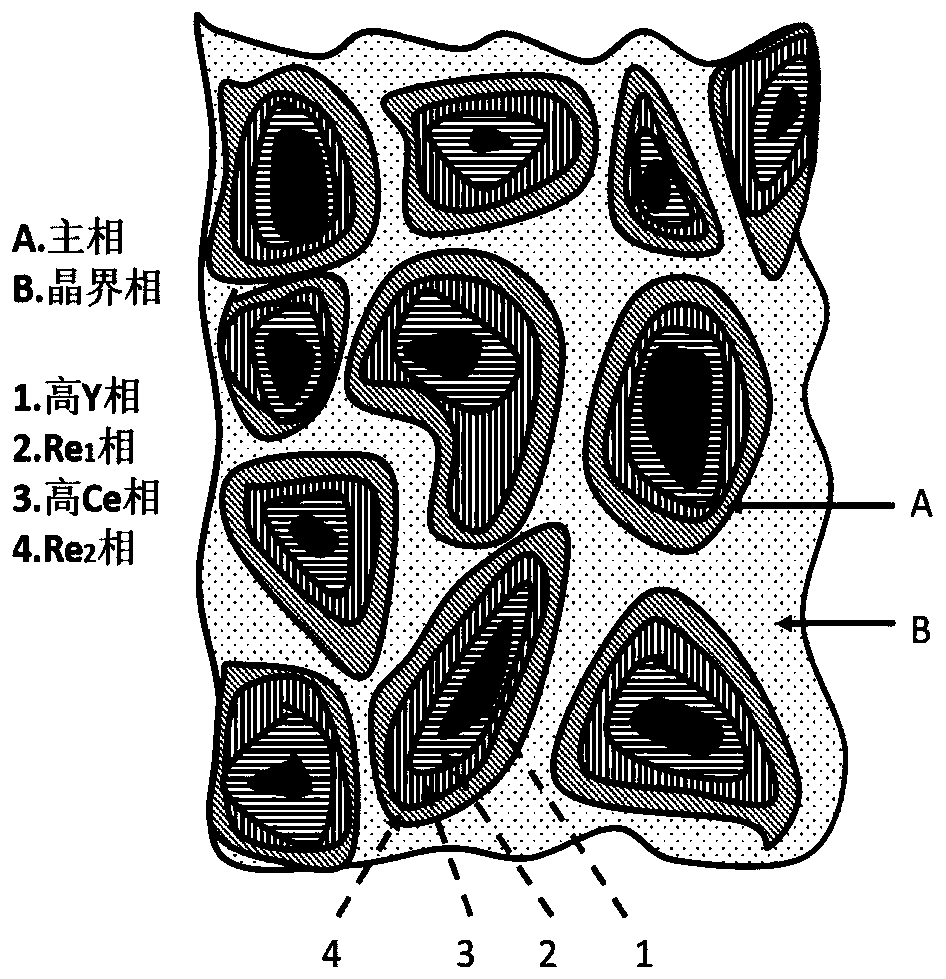

High-performance yttrium-cerium-based rare earth permanent magnet and preparation method thereof

A rare earth permanent magnet, high-performance technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc. problem, to achieve the effect of improving coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the high-performance yttrium-cerium-based rare earth permanent magnet of the present invention comprises the following steps:

[0033] 1) The main phase alloy powder is prepared by quick-setting sheet, hydrogen explosion and jet milling;

[0034] 2) Preparation of grain boundary auxiliary alloy powder by vacuum intermediate frequency induction melting, melting rapid quenching, and ball milling;

[0035] 3) uniformly mixing the main alloy powder and the auxiliary alloy powder, and performing magnetic field orientation molding and isostatic pressing to make a green body;

[0036] 4) The green body is made into a blank after vacuum sintering and tempering;

[0037] The preparation method of the high-performance yttrium-cerium-based rare earth permanent magnet of the present invention: the average particle size of the main phase particle powder is 1-5 microns, and the average particle size of the auxiliary alloy powder is 300-1000 nanometers;

[...

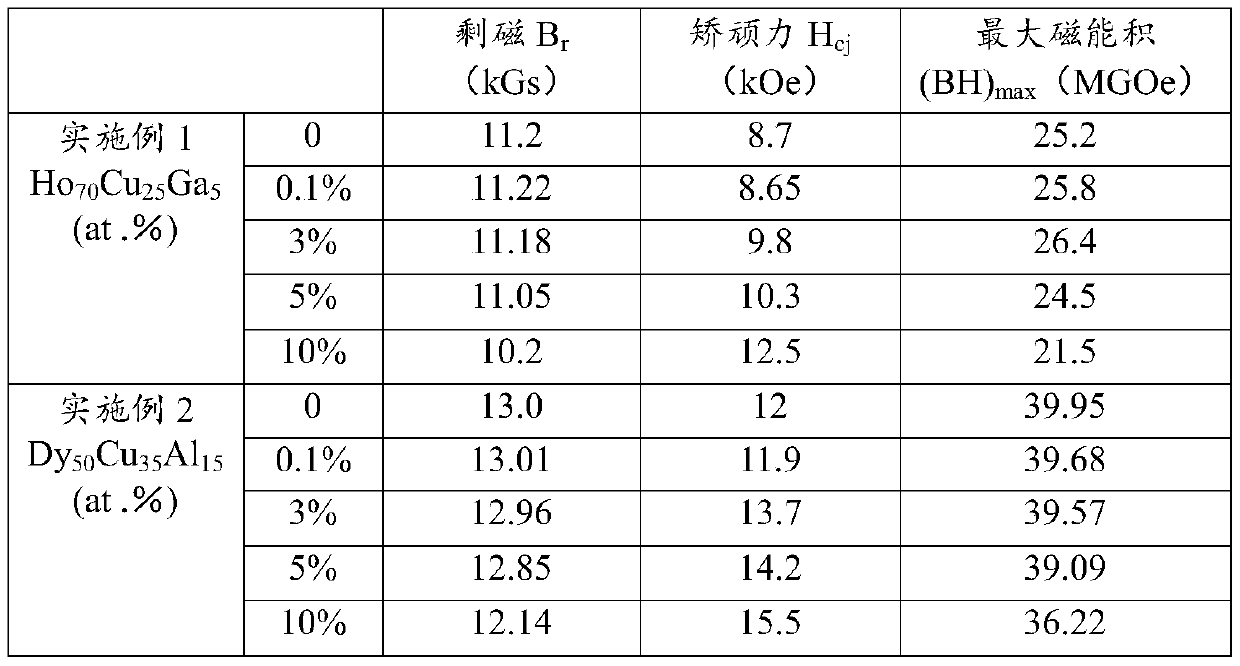

Embodiment 1

[0041] (1) The main phase composition of the yttrium-cerium-based rare earth permanent magnet is (PrNd) 5 Y 4.5 Ce 4.5 Fe 79.05 Cu 0.1 Nb 0.1 al 0.15 co 0.1 B 6.5 (at.%), batching is carried out according to the alloy raw materials required by the composition, the raw materials are polished before batching, and the surface oxide layer and impurities are removed; the alloy raw materials are prepared into a size of 0.15-0.3mm with a quick-setting furnace under the protection of argon quick-setting tablets;

[0042] (2) Use a rotary hydrogen breaking furnace to perform hydrogen breaking treatment on the quick-setting belt, and roughly break the quick-setting belt into particles below 500 μm;

[0043] (3) using inert gases such as high-pressure nitrogen to jet mill the hydrogen powder obtained in step (2) at 0.8Mpa, and make the hydrogen powder into yttrium-cerium-based permanent magnet fine powder with an average particle size of 2-5 μm;

[0044] (4) The composition of t...

Embodiment 2

[0053] (1) The main phase composition of yttrium-cerium-based rare earth permanent magnet is Nd 11.5 Y 1.5 Ce 1.5 Fe 78.65 Nb 0.1 Ga 0.15 co 0.1 B 6.5 (at.%), batching is carried out according to each alloy raw material required for this composition, before batching, the raw material is polished to remove surface oxide layer and impurities; the alloy raw material is prepared into a 0.15-0.3mm alloy raw material under the protection of argon with a quick-setting furnace quick-setting tablets;

[0054] (2) Use a rotary hydrogen breaking furnace to perform hydrogen breaking treatment on the quick-setting belt, and roughly break the quick-setting belt into particles below 500 μm;

[0055] (3) using inert gases such as high-pressure nitrogen to jet mill the hydrogen powder obtained in step (2) at 0.5-1.0 Mpa, and make the hydrogen powder into yttrium-cerium-based permanent magnet fine powder with an average particle size of 2-5 μm;

[0056] (4) The composition of the grain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com