Optical multilayered film bandpass filter

A band-pass filter, optical multilayer film technology, applied in optics, optical components, instruments, etc., to reduce polarization dependence and eliminate ghosting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

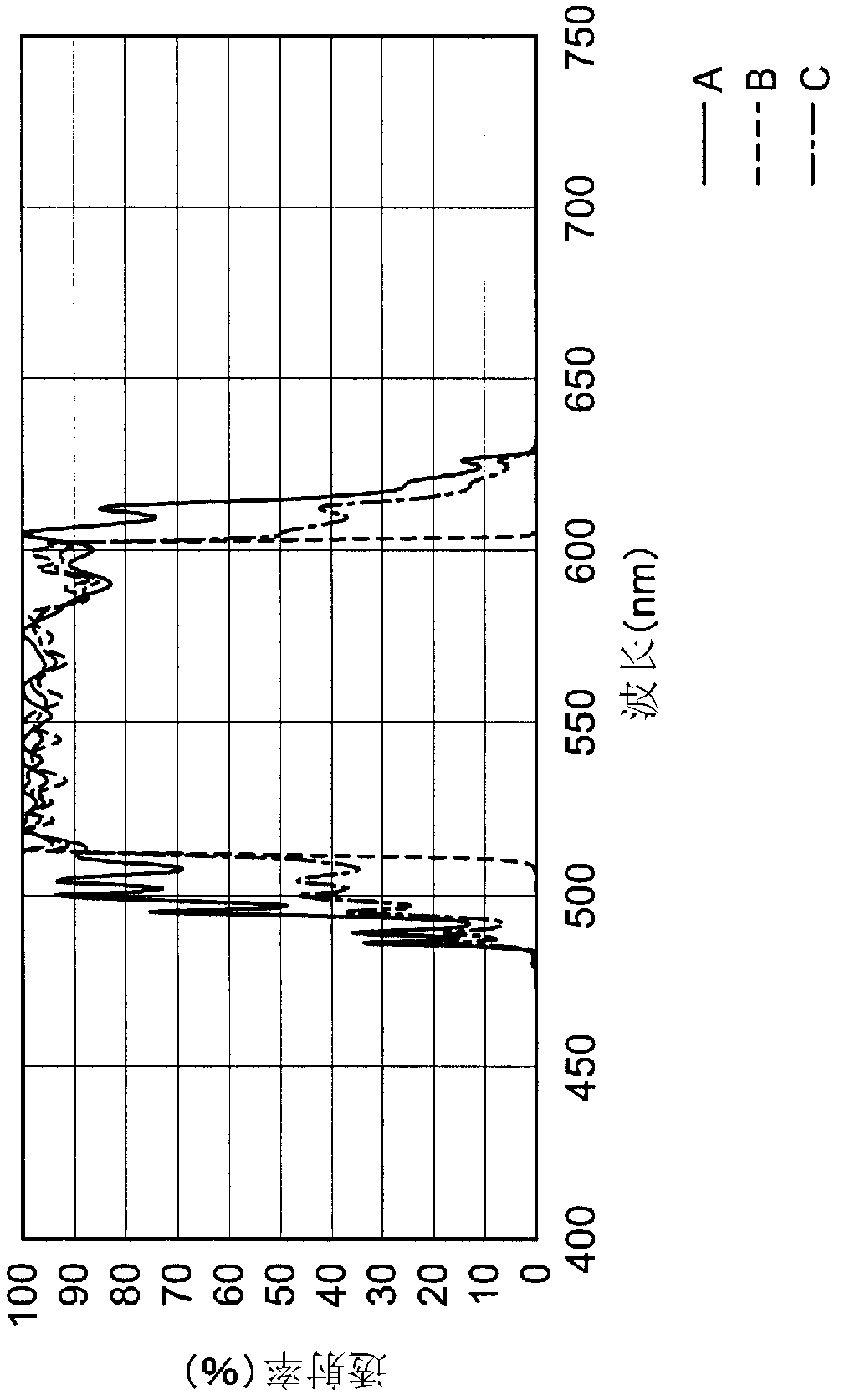

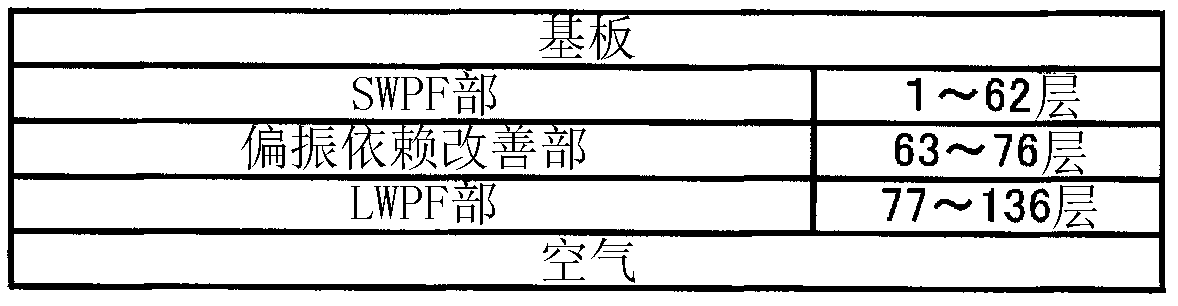

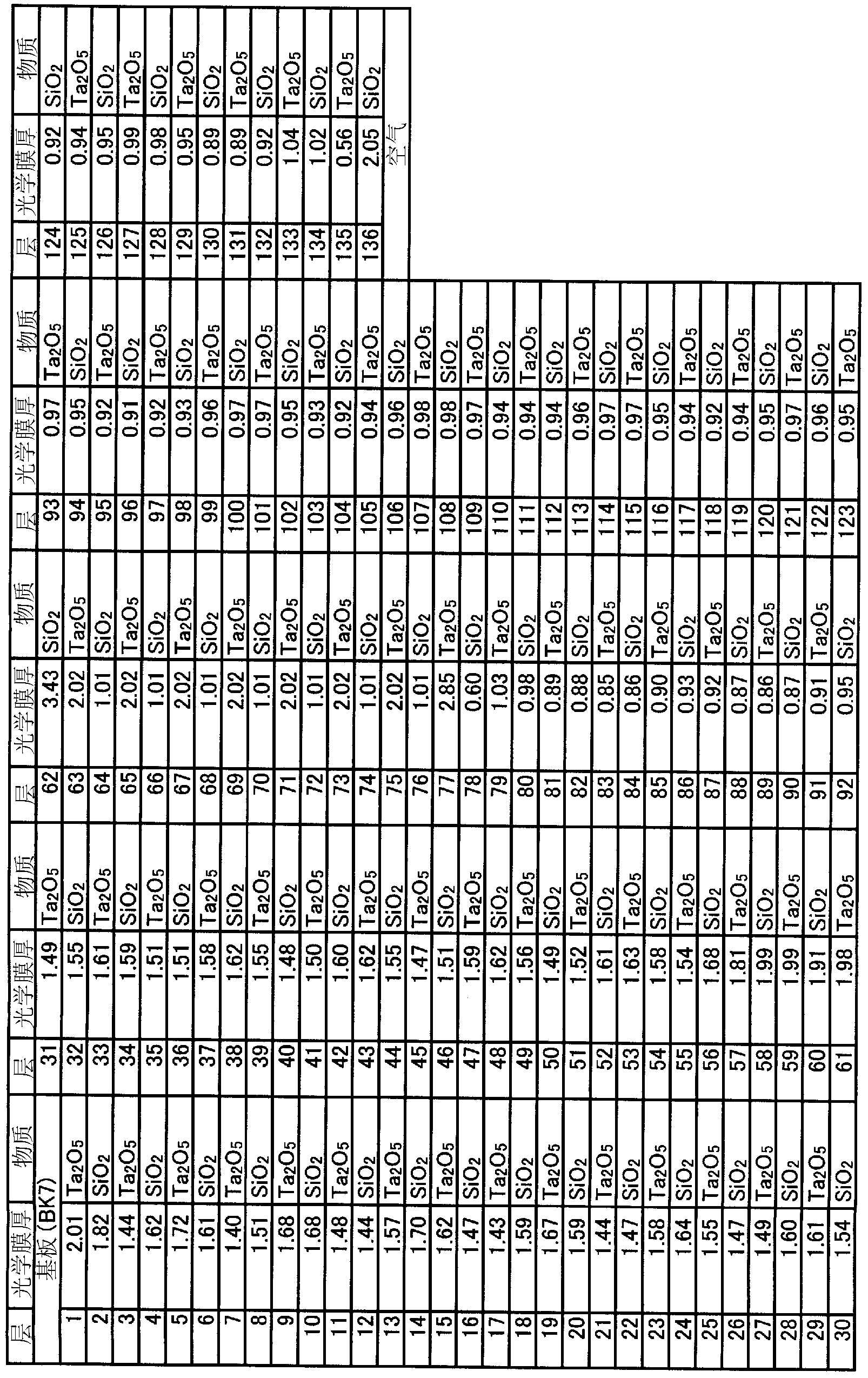

[0099] figure 1 It is a graph showing the bandpass characteristic of the optical multilayer film bandpass filter of Example 1. figure 2 It is a sectional view showing the structure of the optical multilayer film bandpass filter of Example 1. image 3 It is a graph showing the film thickness and constituent substances of each layer of the optical multilayer film bandpass filter of Example 1. exist figure 1 Among them, the solid line A represents the p-polarized light transmission characteristic (Tp), the dotted line B represents the s-polarized light transmission characteristic (Ts), and the dotted line C represents the average (Tmean) of the p-polarized light transmission characteristic and the s-polarized light transmission characteristic. and, in image 3 , shows the optical film thickness (λ / 4=1) when the incident angle is 45 degrees and the wavelength λ of the target light is 498 nm.

[0100] Such as figure 2 , image 3 As shown, the optical multilayer film bandp...

Embodiment 2~ Embodiment 5)

[0111] Figure 7 , Figure 11 , Figure 15 and Figure 19 It is a graph showing the bandpass characteristics of the optical multilayer film bandpass filters of Example 2, Example 3, Example 4, and Example 5, respectively.

[0112] Figure 8 , Figure 12 , Figure 16 and Figure 20 It is a graph showing the bandpass characteristics of the SWPF part, the LWPF part, and the polarization-dependent improvement part in Example 2, Example 3, Example 4, and Example 5, respectively.

[0113] Figure 9 , Figure 13 , Figure 17 and Figure 21 It is a sectional view showing the structure of the optical multilayer film bandpass filter of Example 2, Example 3, Example 4, and Example 5, respectively.

[0114] Figure 10 , Figure 14 , Figure 18 and Figure 22 It is a graph showing the film thickness and constituent substances of each layer of the optical multilayer film bandpass filters of Example 2, Example 3, Example 4, and Example 5, respectively.

[0115] exist Figure...

Embodiment 2

[0129] (1) Example 2: high refractive index layer > low refractive index layer ( Figure 7 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com