Side-polished polymer temperature sensing fiber and manufacturing method thereof

A technology for sensing optical fibers and polymers, which is applied in the field of optical fiber evanescent wave sensors, side-throw polymer temperature sensing optical fibers and manufacturing methods thereof, can solve the problems of low detection sensitivity and complex preparation process, and achieve high sensitivity and Low temperature output, good repeatability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

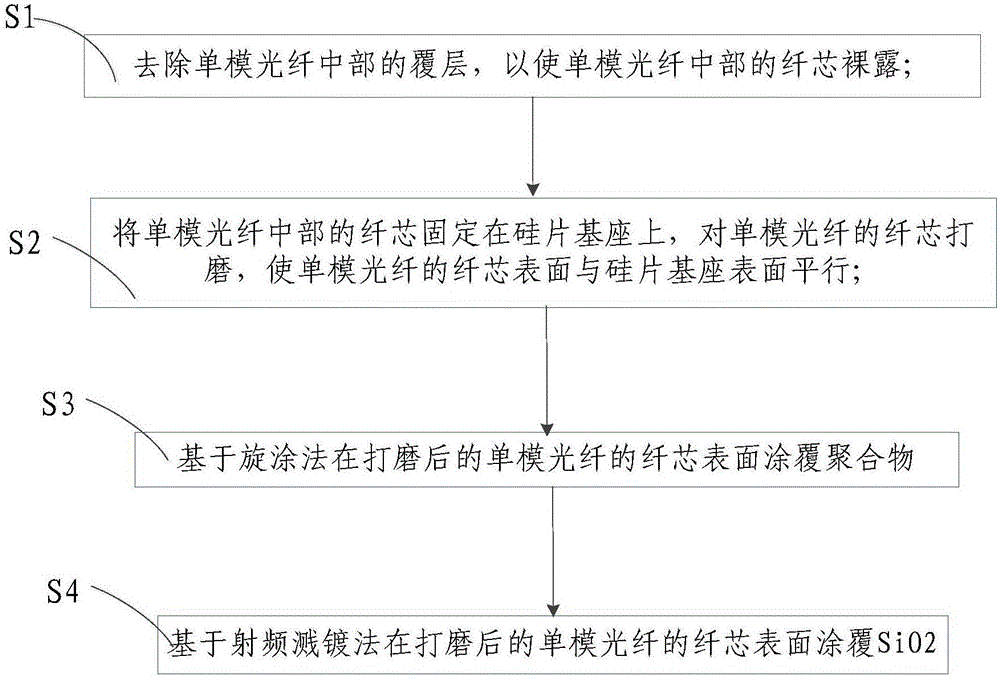

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

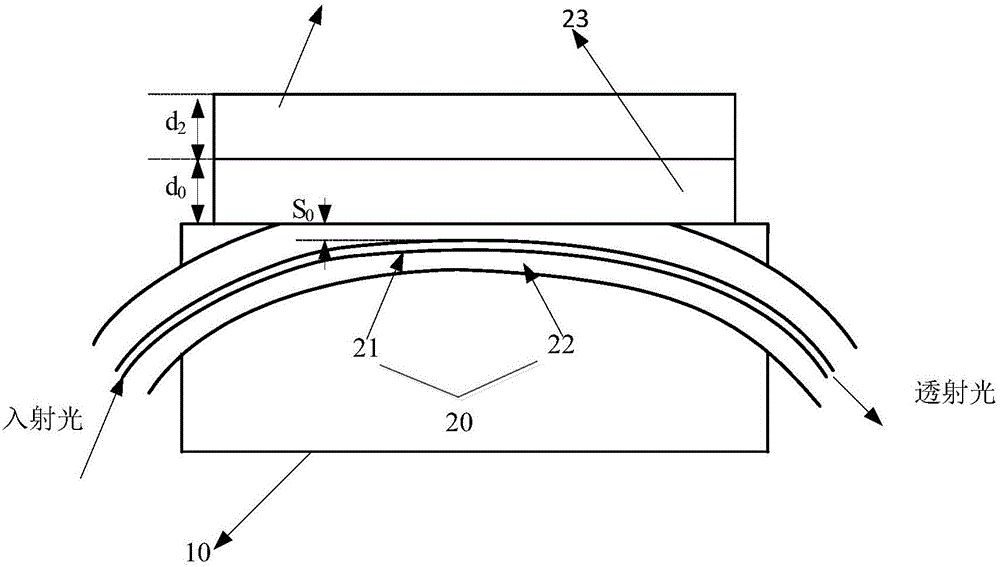

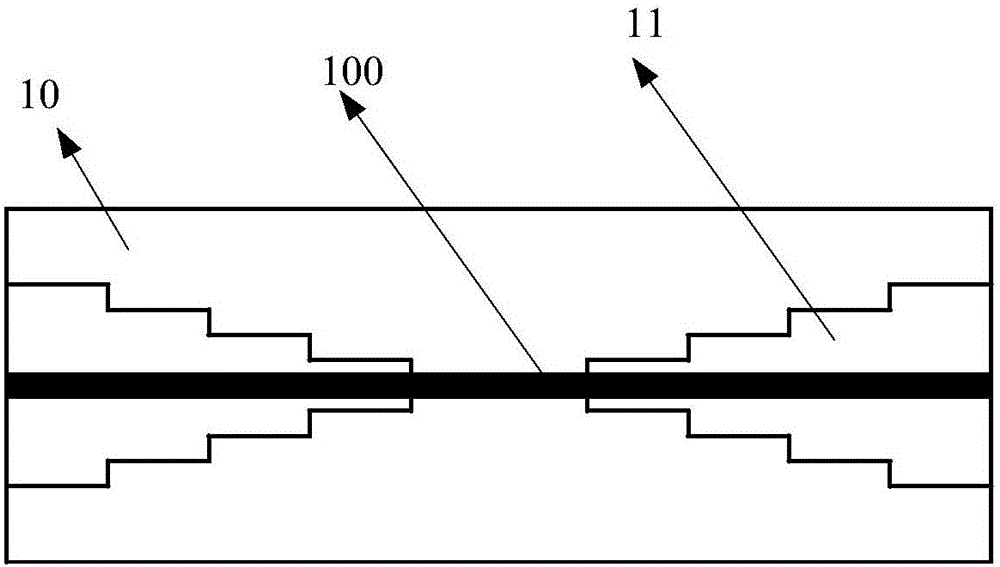

[0028] see figure 1 As shown, the present invention provides a side-throwing polymer temperature sensing optical fiber, which includes a silicon wafer base 10 and an arc-shaped single-mode optical fiber 20, wherein the core 21 in the middle of the single-mode optical fiber 20 is exposed on the surface , and the middle part of the single-mode optical fiber 20 is fixed on the silicon wafer base 10 through the core 21 exposed on the surface, and the core 21 in the middle of the single-mode optical fiber 20 is provided with a polymer on the side away from the silicon wafer base 10. The coating 23 and the SiO2 coating layer 2224 , the SiO2 coating layer 2224 is fixed on the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com