Reflectivity measuring system

A measurement system and reflectivity technology, applied in the measurement of scattering characteristics, etc., can solve problems such as difficult assembly, error reduction, and complex structure, and achieve the effects of optical path assembly and light alignment, reduced polarization dependence, and accurate reflectivity measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The reflectance measuring system of the present invention is suitable for measuring the surface reflectance of various optical components, and is especially suitable for measuring the surface reflectance of an optical component whose surface to be measured is a curved surface.

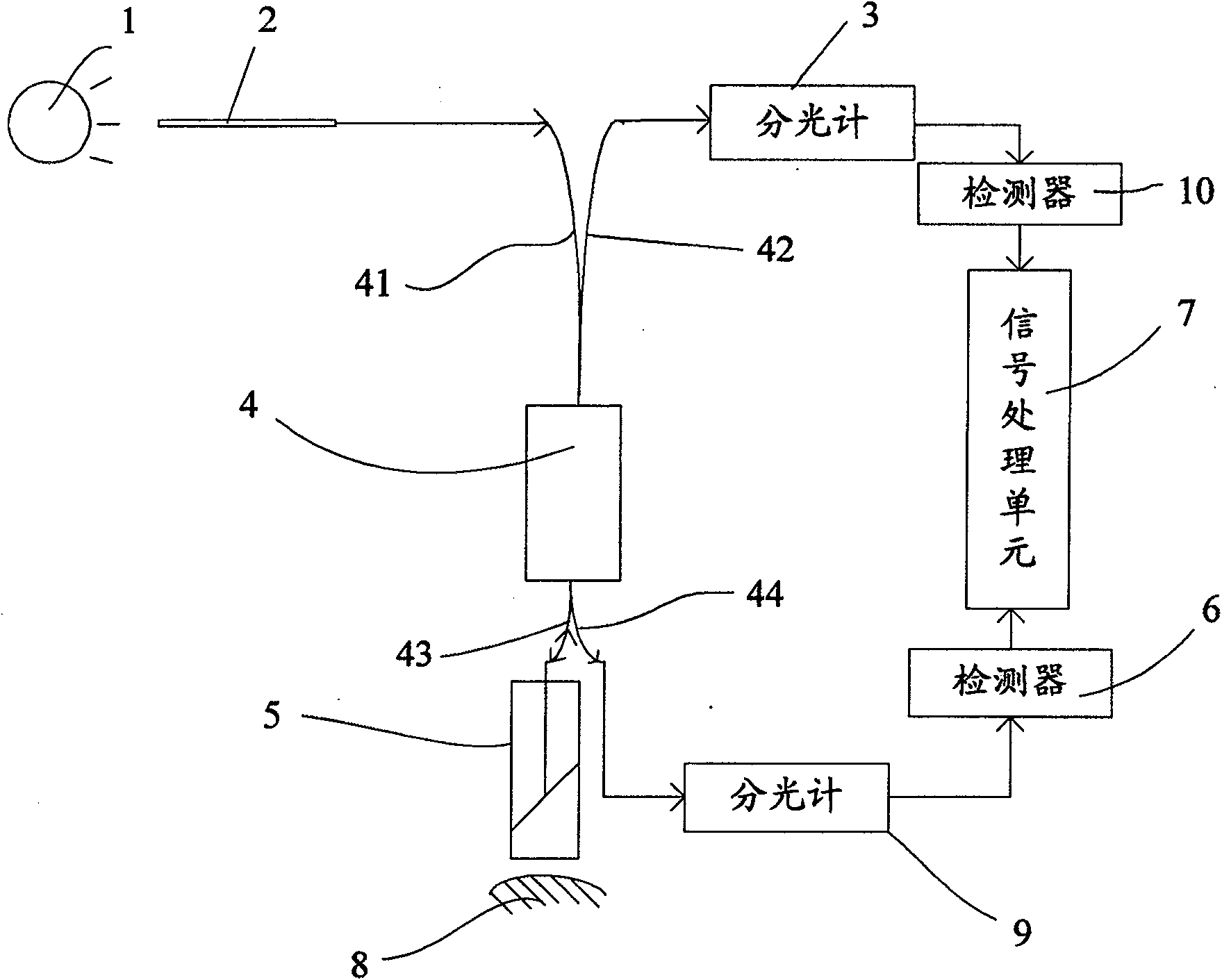

[0009] see figure 1 , the reflectivity measurement system includes a light source 1, a polarization maintaining fiber 2, a first spectrometer 3 (spectrometer), a polarization maintaining fiber direction coupler 4, a collimator lens 5, a first detector 6 (detector ), a signal processing unit 7, a second spectrometer 9 and a second detector 10, the reflectance measurement system is used to measure the reflectance of the surface of the object to be measured 8.

[0010] The light source 1 is a white light source, such as a halogen lamp, and 99.9% of its light is non-polarized light. The light source 1 is driven by AC (Alternating Current) modulation, so that the light emitted by the light source 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com